Preparation method and application of antimony nanoparticle/nitrogen-doped carbon nano necklace composite material (Sb/N-CNN)

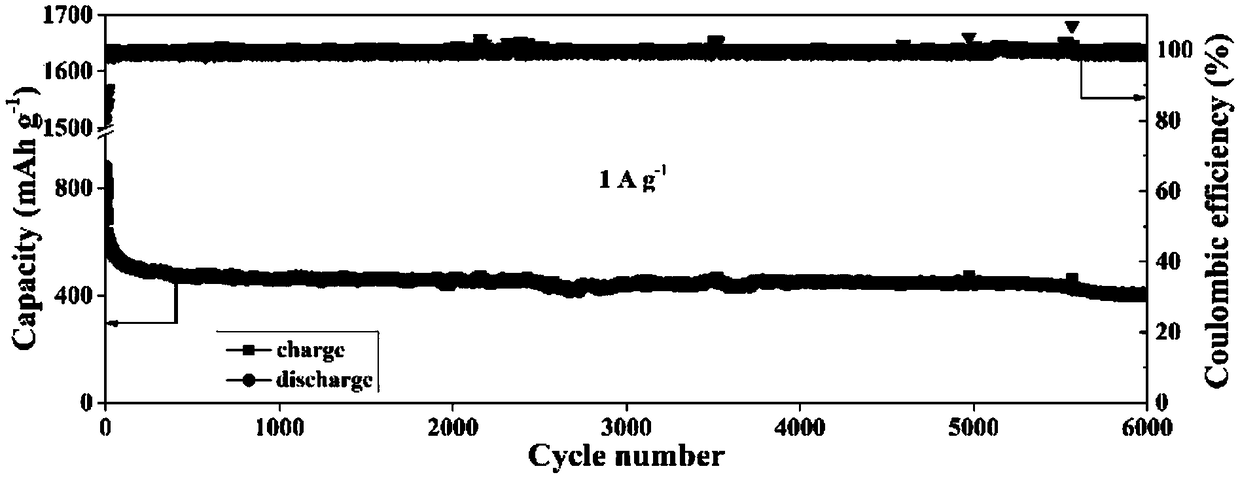

A nanoparticle, nitrogen-doped carbon technology, applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve problems such as limited effects, and achieve high electrical conductivity, excellent rate performance, and fast electrochemical reaction rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

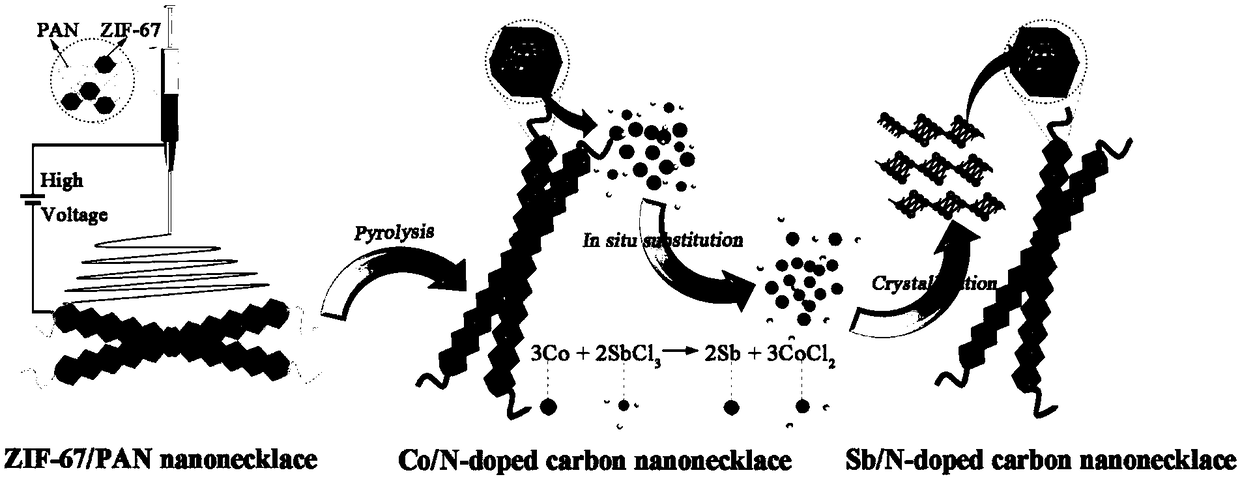

[0054] The preparation process and steps in this embodiment are as follows:

[0055] (1) Preparation of ZIF-67: 1.487g Co(NO 3 ) 2 ·6H 2 O was dissolved in 100ml of methanol, 3.284g of 2-methylimidazole was dissolved in 50ml of methanol, and the two solutions were mixed and stirred for 2h, the product was centrifuged, washed with methanol and water for 3 times, and vacuum-dried at 70°C for 12h;

[0056] (2) Spinning ZIF-67 and PAN to prepare ZIF-67 / PAN-nanochains by electrospinning: take 0.263g ZIF-67 and ultrasonically disperse it in 2.063g of N,N-dimethylformamide, add 0.175 g polyacrylonitrile, stirred at room temperature for 24 hours, and then spun, the voltage was 18kV, the needle type was No. 19, the distance between the needle and the receiver was 18cm, and the ambient temperature was 35°C;

[0057] (3) The prepared ZIF-67 / PAN-nano chains were heated in a tube furnace with 5% H 2 In / Ar atmosphere, first anneal at 250°C for 1.5h, then raise the temperature to 700°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com