A deep hole pre-splitting blasting method in coal mine roof

A technology of pre-splitting blasting and roofing, which is applied in blasting and other directions, and can solve problems such as roof rotation pressure and achieve the effect of preventing residual blasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

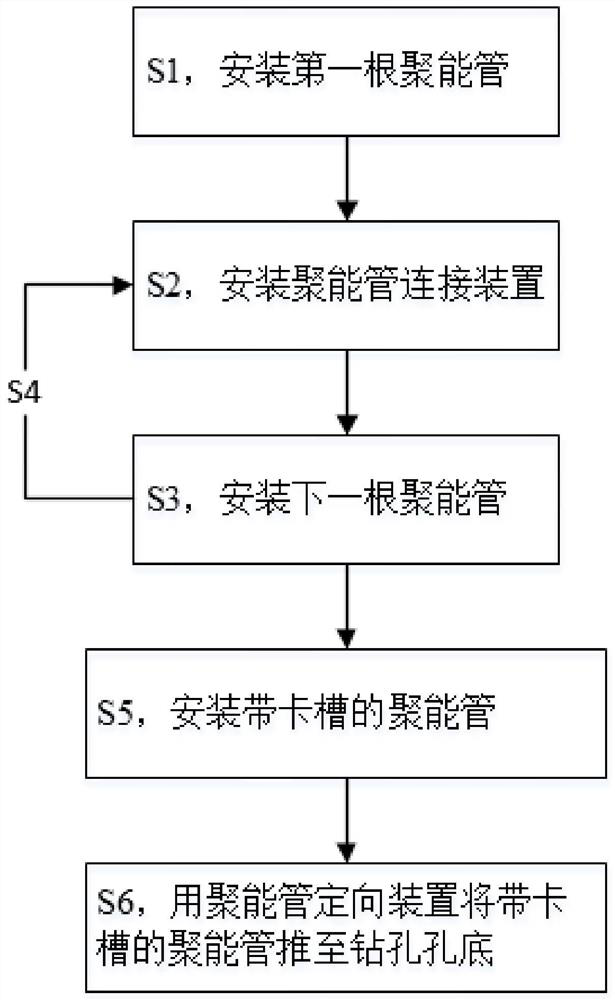

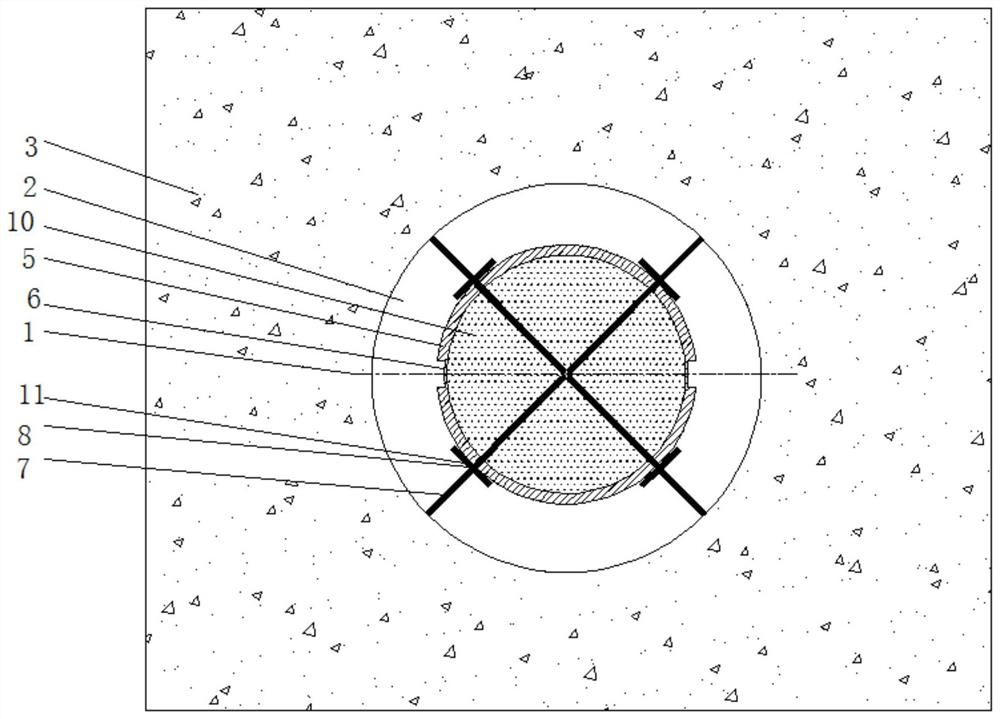

Method used

Image

Examples

Embodiment 1

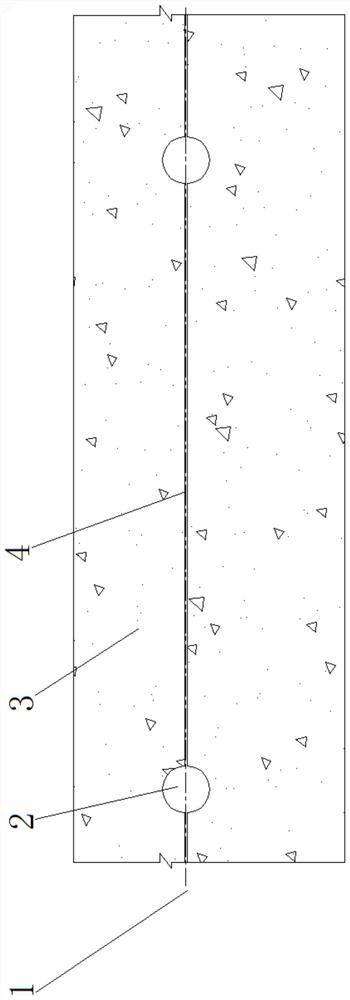

[0080] Qinhe Energy Group Zhongcun Coal Industry Co., Ltd. has a coal seam thickness of 3.1m and a full height in one mining operation. Due to the high strength of the roof, the roof and floor of the adjacent roadway will move a lot after the coal mining face is pushed through before taking measures to cut the roof. The pressure is high, the roadway is partially damaged, and it needs to be repaired before it can be used;

[0081] It was decided to use roof cutting to reduce the roof pressure of the roadway. First, the roof was drilled to take cores. It was measured that the range of 0-30m above the roof was mudstone and sandstone respectively. The obtained mechanical parameters are as follows:

[0082] Uniaxial compressive strength R = 62.3Mpa; tensile strength Rm = 9.07Mpa; shear strength τ = 36.86Mpa, cohesion c = 13.29Mpa; internal friction angle φ = 28.65°; elastic modulus E = 4845Mpa; Poisson's ratio μ=0.27; the average coefficient of disintegration K=1.32, and the avera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com