PE pipe blasting construction process for open-air fracture-developed rock stratum

A construction technology and rock formation technology, which is applied in the field of PE pipe blasting construction technology in open-air fissures developed rock formations, can solve the problems of uneven distribution of explosives, influence of blasting effect, and increased consumption of explosives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

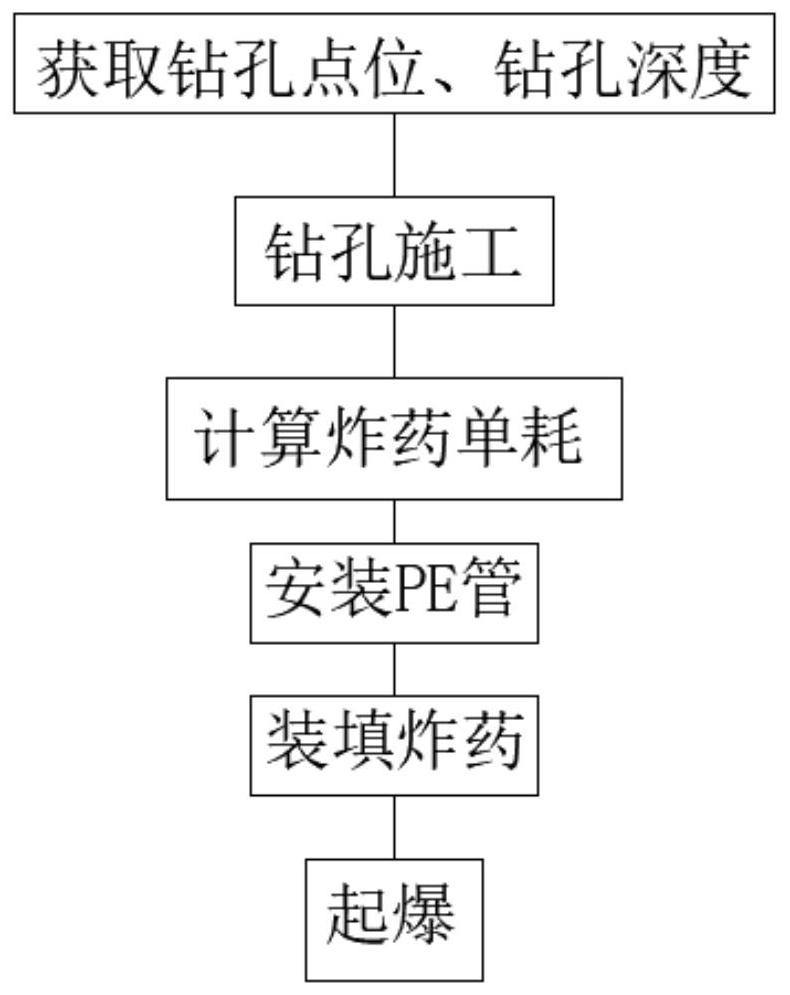

[0054] like Figure 1-12 As shown, the embodiment of the present invention provides a blasting construction process for PE pipes in rock formations with open-air fractures, including the following steps:

[0055] Step 1: Obtain drilling information according to the on-site rock formation conditions;

[0056] Step 2: Carry out drilling construction according to the obtained drilling information;

[0057] Step 3: Calculate the unit consumption of explosives according to the drilling;

[0058] Step 4: Install the PE pipe in the borehole and fill the PE pipe with explosives according to the calculated unit consumption of explosives;

[0059] Step 5: Detonate the explosives filled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com