A kind of automatic filling and sealing rotary valve for cream

A fully automatic, rotary valve technology, applied in the field of rotary valves, can solve problems such as affecting production quality, occurrence of empty pipes, damage to valve core connecting rods, etc., to solve the problem of drug leakage, avoid empty pipes, and avoid wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

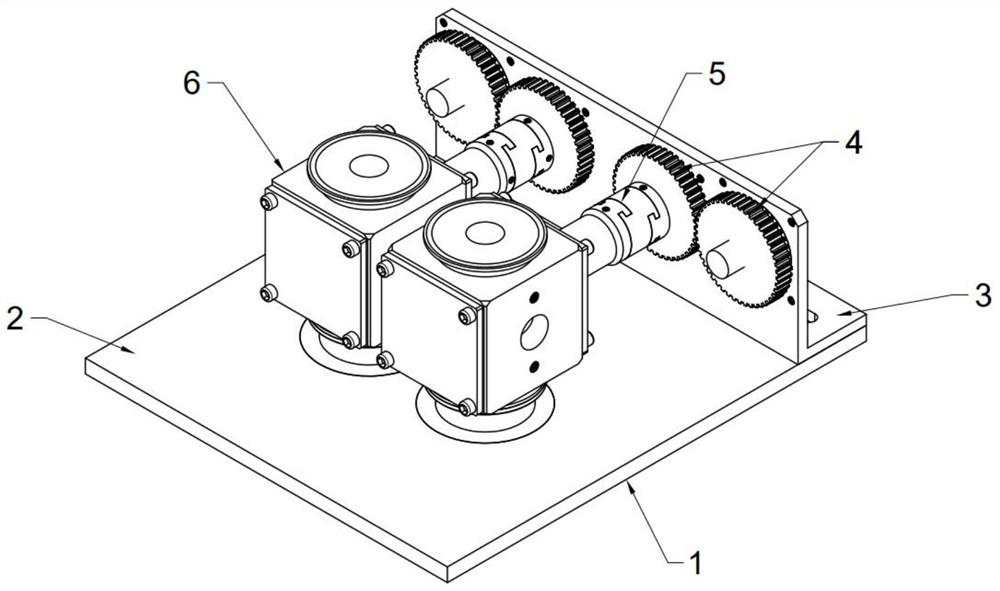

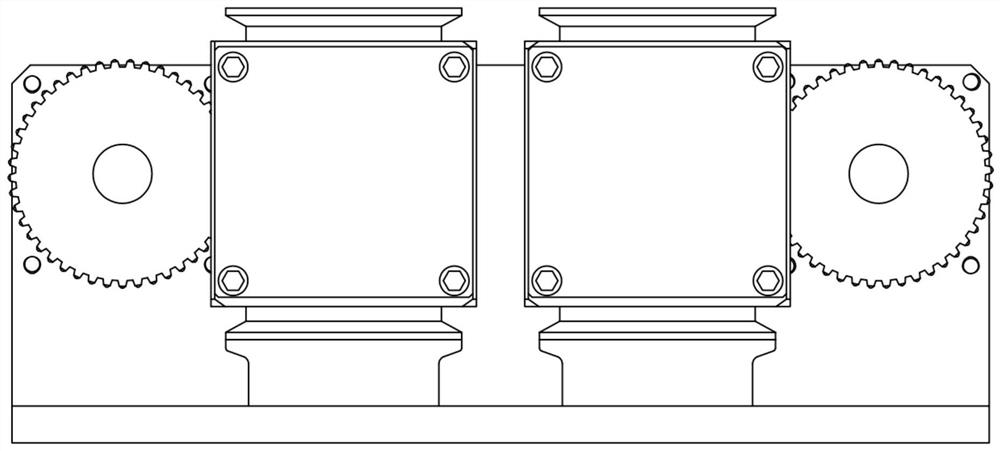

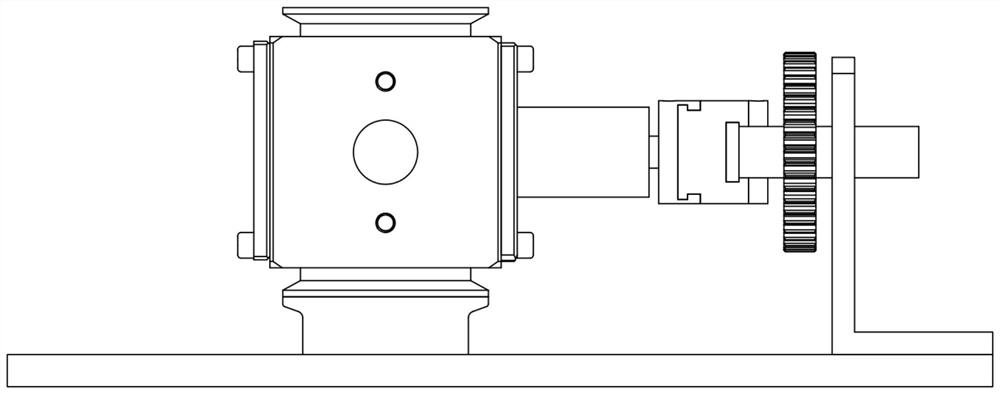

[0039] combine Figure 1-8 As shown, the present invention provides a fully automatic filling and sealing rotary valve for cream, which includes a fixed seat 1, a transmission gear 4, a coupling 5 and a rotary valve 6. The fixed seat 1 is divided into a fixed bottom plate 2 and an L-shaped support plate 3, the fixed bottom plate 1 is a square flat plate placed horizontally, an L-shaped support plate 3 is fixed on one side of its upper surface; the transmission gear 4 is rotatably fixed on the L-shaped support plate 3, and the Two groups of rotary valves 6 are fixed side by side on the upper surface of the fixed bottom plate 2, and each group of rotary valves is connected with the transmission gear 4 through the coupling 5, and the characteristics are as follows:

[0040]The rotary valve 6 includes a valve core 602 and a valve sleeve 601, and the valve core 602 is rotatably fixed in the valve sleeve 601; the valve core 602 is a stepped shaft, which is divided into a shaft body,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com