Environmentally-friendly low-fluorescence imitation asphalt plugging agent

A plugging agent, polyethylene glycol technology, applied in the field of oil drilling, can solve the problems of unsatisfactory anti-slump plugging, high fluorescence level, limited plugging effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Plugging agent a is composed of the following components in various mass percentages:

[0032] Polyamide wax powder 10%,

[0033] Oxidized Polyethylene Wax 20%,

[0034] PAC 5%,

[0035] Macrogol 20%,

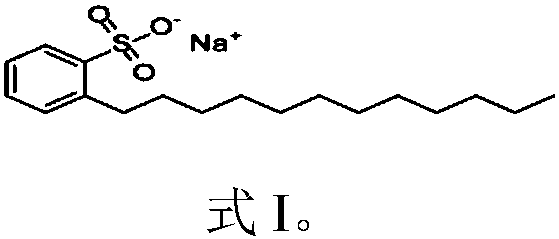

[0036] Sodium dodecylbenzenesulfonate 2%,

[0037] Nano calcium carbonate 10% with a particle size of 40-70nm,

[0038] The balance is water.

[0039] Put the above components into the reaction kettle one by one according to the above arrangement order. After heating up to 120°C, stir at a constant temperature for 60 minutes. After all the components are completely mixed evenly, then cool down to normal temperature and pressure and stir at a high speed. Discharge after 30 minutes, dry at 120°C for 180 minutes, pulverize and granulate, and pass through a 200-mesh sieve.

Embodiment 2

[0041] The plugging agent b is composed of the following components in various mass percentages:

[0042] Polyamide wax powder 15%,

[0043] Oxidized Polyethylene Wax 25%,

[0044] PAC 8%,

[0045] Macrogol 25%,

[0046] Sodium dodecylbenzenesulfonate 3%,

[0047] Nano calcium carbonate 15% with a particle size of 40-70nm,

[0048] The balance is water.

[0049] The preparation method is the same as in Example 1, only the dosage of each component is replaced accordingly.

Embodiment 3

[0051] The plugging agent c is composed of the following components in various mass percentages:

[0052] Polyamide wax powder 20%,

[0053] Oxidized Polyethylene Wax 20%,

[0054] PAC 5%,

[0055] Macrogol 20%,

[0056] Sodium dodecylbenzenesulfonate 5%,

[0057] Nano calcium carbonate 15% with a particle size of 40-70nm,

[0058] The balance is water.

[0059] The preparation method is the same as in Example 1, only the dosage of each component is replaced accordingly.

[0060] Examples 1-3 According to the prepared environmentally friendly and easy-degradable imitation asphalt low-fluorescence plugging agent, the drilling fluid was prepared according to the following procedures and its performance was tested. For specific performance tests, refer to GB / T 16783.1-2006 Petroleum and Natural Gas Industry Drilling Fluid Field Test Part 1 : Water-based drilling fluid.

[0061] 1. Base slurry configuration program

[0062] 1) Take 400ml of fresh water, add 8g of bentonite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com