Lignin modification method and preparation method of lignin-based epoxy resin

A technology based on epoxy resin and lignin, which is applied in the field of compound modification, can solve the problems of non-biodegradable toxicity and the complexity of ionic liquid synthesis, and achieve the effects of alleviating the energy crisis, easy implementation, and high utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

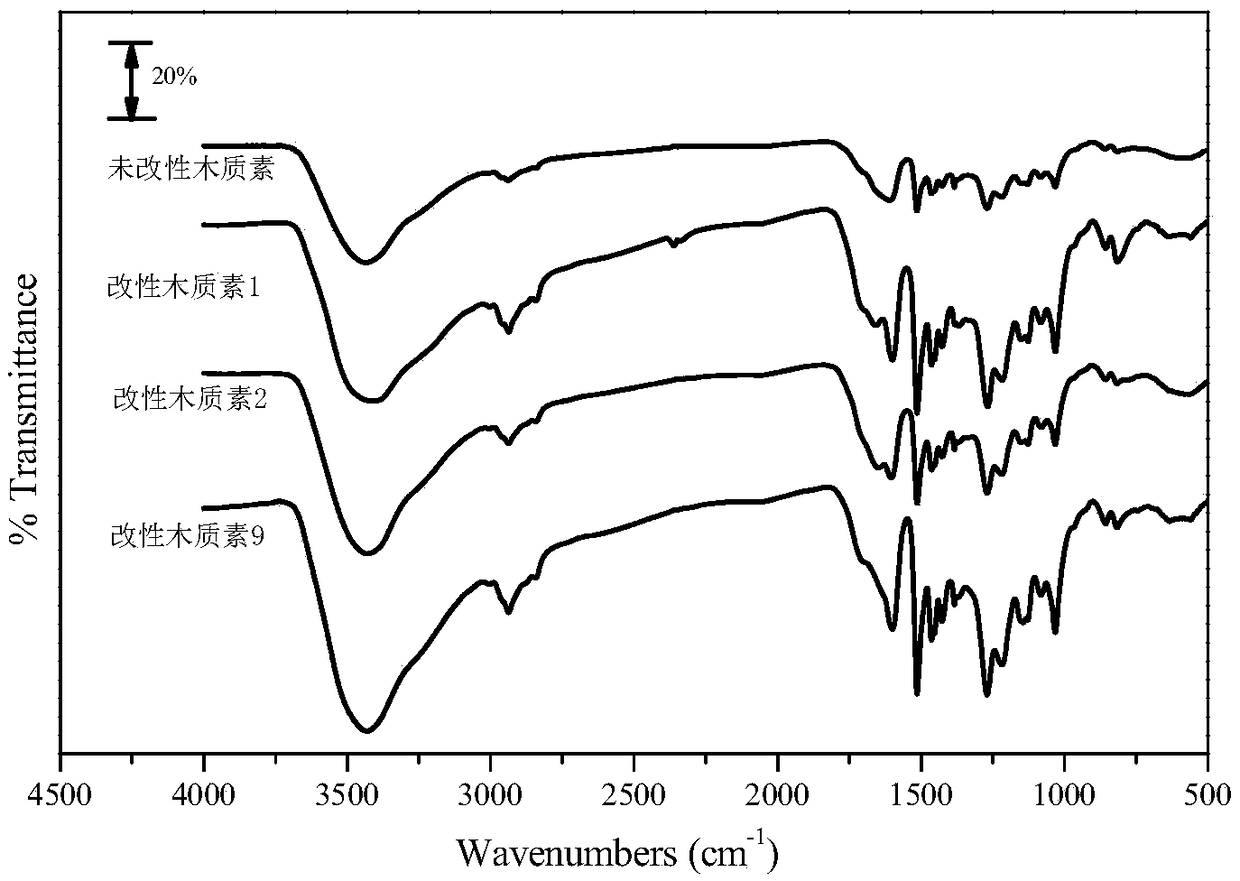

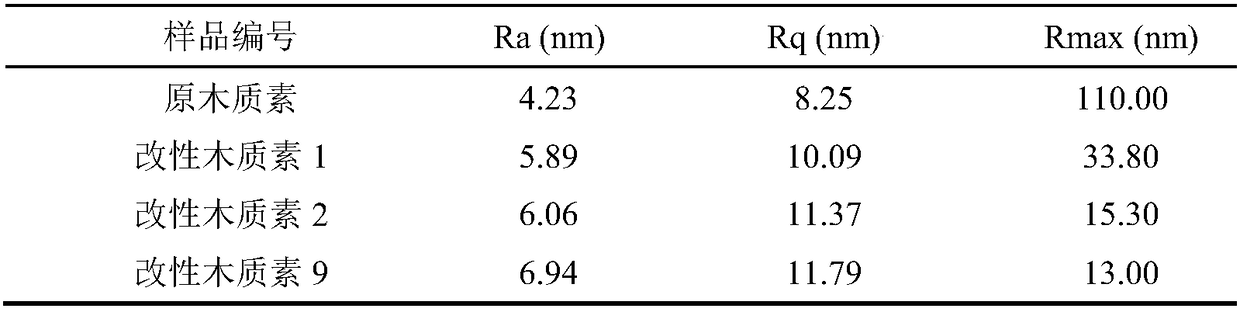

[0029] Modification of lignin

[0030] Weigh choline chloride and urea into a 250mL beaker, stir in a water bath at 70°C until a uniform solution is formed, and obtain eutectic melt I with a molar ratio of choline chloride and urea of 2.1; weigh 1.0g of wood Plain element and 0.1g nickel oxide are placed in the autoclave, the eutectic melt I that will make is added in the autoclave (the mass ratio of lignin, eutectic melt and metal oxide is 1:20:0.1), in Under 1Mpa nitrogen atmosphere, react at 80°C and 100r / min for 2h under continuous stirring, then wash the product with water, centrifuge, filter, and vacuum dry to obtain modified lignin 1.

Embodiment 2

[0032] Modification of lignin

[0033] Weigh choline chloride and urea into a 250mL beaker, stir in a water bath at 100°C until a uniform solution is formed, and obtain eutectic melt I with a molar ratio of choline chloride and urea of 2.5; weigh 1.0g of wood Primer and 0.1g cobalt oxide are placed in the autoclave, and the eutectic I made is added in the autoclave (the mass ratio of lignin, eutectic and metal oxide is 1:40:0.1), in Under 1Mpa nitrogen atmosphere, react at 110°C and 100r / min for 5h under continuous stirring, then wash the product with water, centrifuge, filter, and vacuum dry to obtain modified lignin 2.

Embodiment 3

[0035] Modification of lignin

[0036] Weigh choline chloride and urea and place them in a 250mL beaker, stir in a water bath at 90°C until a uniform solution is formed to obtain eutectic melt I with a molar ratio of choline chloride and urea of 4; weigh 1.0g Lignin and 0.5g chromium oxide are placed in the autoclave, and the eutectic I made is added in the autoclave (the mass ratio of lignin, eutectic and metal oxide is 1:30:0.5), Under 1Mpa nitrogen atmosphere, react at 100°C and 200r / min for 4h under constant stirring, then wash the product with water, centrifuge, filter, and vacuum dry to obtain modified lignin 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com