Billet centering device

A technology of centering device and billet, applied in the field of billet centering device, can solve the problems of long production line, untimely steel mill, damage to the end of the push rod, etc., and achieve the effect of reducing length, reducing temperature drop, and buffering collision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

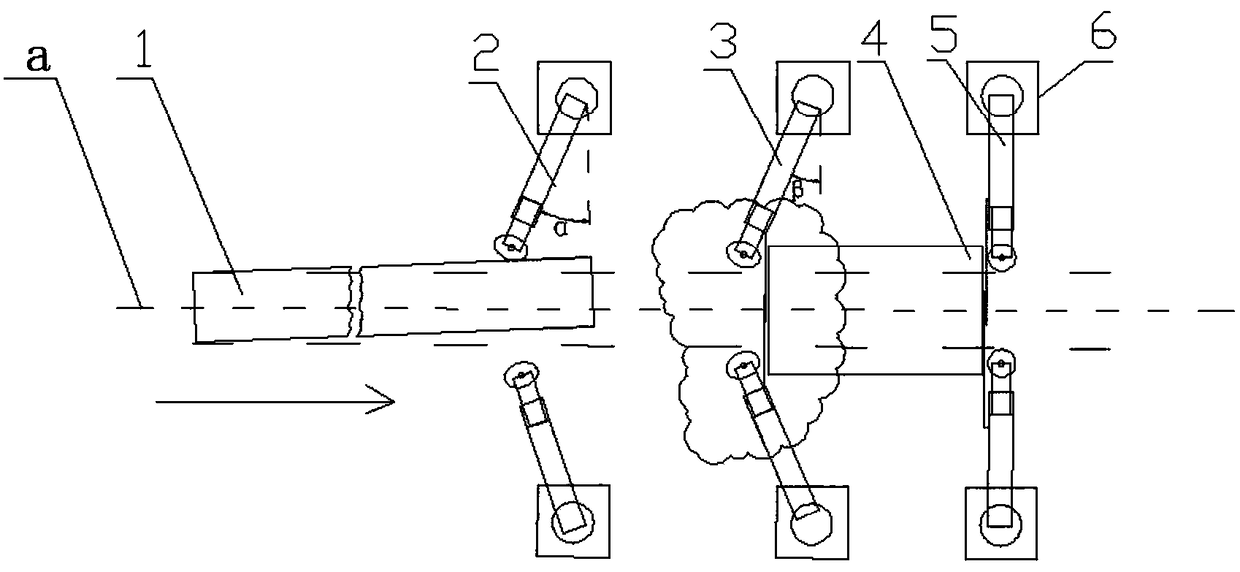

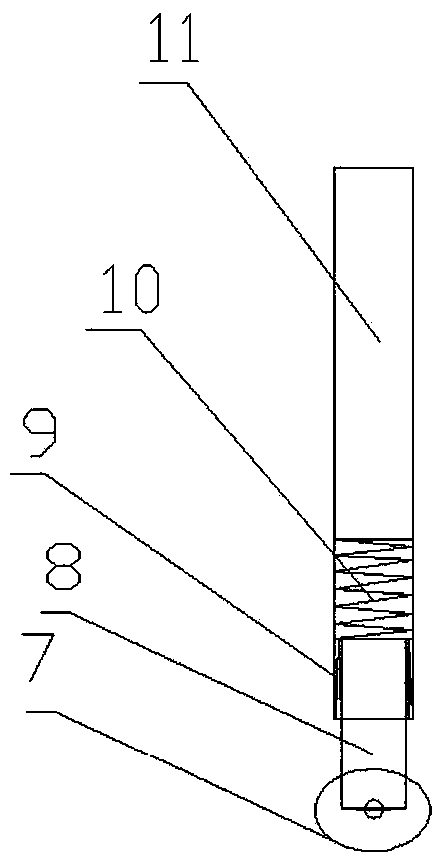

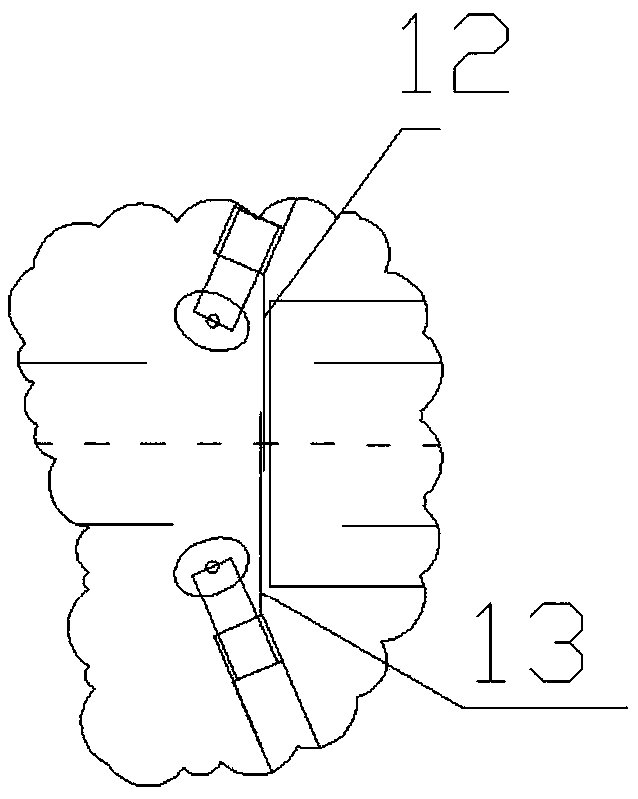

[0021] Such as figure 1 As shown, a billet centering device includes a pair of front push rods 2, a pair of middle push rods 3 and a pair of rear push rods 5, all of which are symmetrical about the center line a of the roller table. The front push rods 2 are located upstream of the middle push rods 3 , the middle push rod 3 and the rear push rod 5 are respectively located at the inlet side and the outlet side of the descaling box 4, and the ends of the front push rod 2, the middle push rod 3 and the rear push rod 5 are top wheels 7 that can be stretched along the rod direction And the restoring force of the top wheel 7 in the rod direction is provided by the main spring 10, the top wheel 7 of the front push rod 2 is biased upstream and the angle between the front push rod 2 and the vertical line a of the center line of the roller table is α, the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com