Method for 3D printing of rapidly renewable cobalt-chromium alloy coated tooth

A 3D printing, cobalt-chromium alloy technology, applied in 3D printing, dentures, dentistry, etc., can solve the problems of unattractive pure metal materials, brittle pure ceramic materials, and loose bite, so as to shorten the time required for rehabilitation and reduce work. Quantity, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

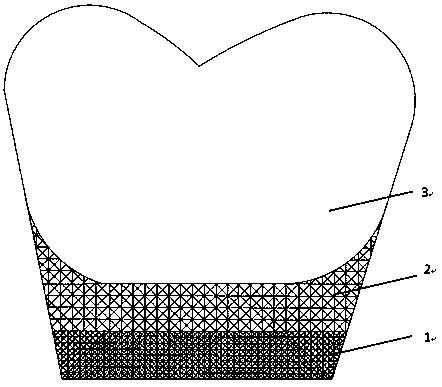

[0031] The 3D printing method of the present embodiment fast renewable cobalt chromium alloy coating tooth, it comprises the following steps:

[0032] (1) Obtaining denture size information: use a laser scanning device to scan the shape of the teeth occluded with the denture to obtain 3D data information on the surface topography of the denture, and then import it into the computer 3D software UG to continuously improve the 3D data information on the denture surface. Then convert the 3D model generated in the computer into an STL file and import it into the 3D printer control software.

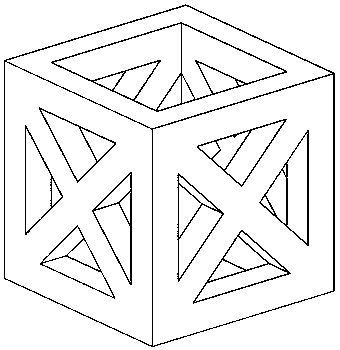

[0033] (2) 3D printed denture main body: select zirconia powder mixed with a small amount of graphene and carbon nanotube powder, grind it with a ball mill until the particle size of the powder is less than 100um, fill it with protective gas and heat it up to 900°C, according to the imported 3D The main body of the denture is 3D printed by a 3D printer, and the laser is used for heat treatment...

Embodiment 2

[0039] The 3D printing method of the present embodiment fast renewable cobalt chromium alloy coating tooth, it comprises the following steps:

[0040] (1) Obtaining denture size information: use a laser scanning device to scan the shape of the teeth occluded with the denture to obtain 3D data information on the surface topography of the denture, and then import it into the computer 3D software UG to continuously improve the 3D data information on the denture surface. Then convert the 3D model generated in the computer into an STL file and import it into the 3D printer control software.

[0041] (2) 3D printed denture main body: select zirconia powder mixed with a small amount of graphene and carbon nanotube powder, grind it with a ball mill until the particle size of the powder is less than 100um, fill it with protective gas and heat it up to 1000°C, according to the imported 3D The main body of the denture is 3D printed by a 3D printer, and the laser is used for heat treatmen...

Embodiment 3

[0047] The 3D printing method of the present embodiment fast renewable cobalt chromium alloy coating tooth, it comprises the following steps:

[0048] (1) Obtaining denture size information: use a laser scanning device to scan the shape of the teeth occluded with the denture to obtain 3D data information on the surface topography of the denture, and then import it into the computer 3D software UG to continuously improve the 3D data information on the denture surface. Then convert the 3D model generated in the computer into an STL file and import it into the 3D printer control software.

[0049] (2) 3D printed denture main body: select zirconia powder mixed with a small amount of graphene and carbon nanotube powder, grind it with a ball mill until the particle size of the powder is less than 100um, fill it with protective gas and heat it up to 1100°C, according to the imported 3D The main body of the denture is 3D printed by a 3D printer, and the laser is used for heat treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com