Calorimetry testing method and device for tubular reaction

A technology of tube reaction and test method, applied in the direction of measuring device, calorimeter, measuring heat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

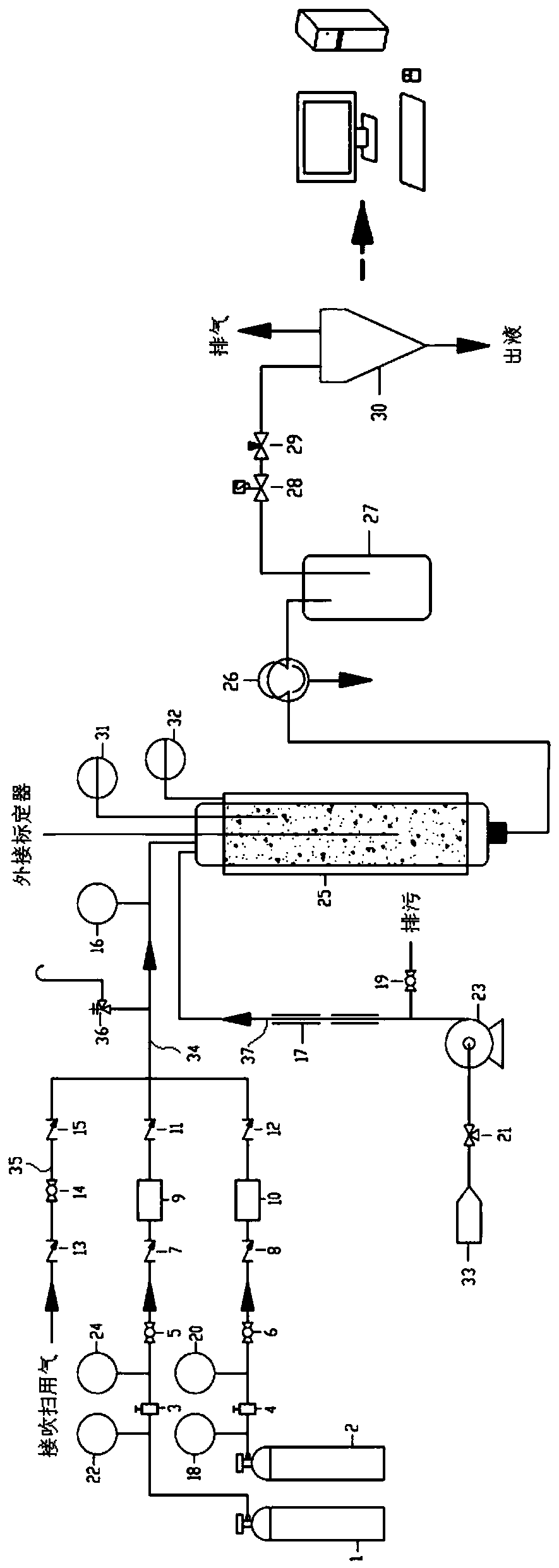

[0070] like figure 1 As shown, the device comprises a first feeding system, a second feeding system, a reactor 25, a sampler 26, a material collector 27 and a gas-liquid separator 30, wherein the first feeding system passes through a first input pipeline 34 and reacts The input end of the reactor 25 is connected, the second feeding system is connected with the input end of the reactor 25 through the second input pipeline 37, and the output end of the reactor 25, the sampler 26, the material collector 27 and the gas-liquid separator 30 are connected in series successively, the described The first feeding system includes a raw material liquefaction bottle, a feeding pipeline and a purge gas pipeline 35, the raw material liquefaction bottle is connected to the feeding pipeline one by one, each feeding pipeline and the purge gas pipeline 35 are arranged in parallel and The output ends are all connected to the first input pipeline 34, and ball valves and mass flow meters are sequen...

Embodiment 2

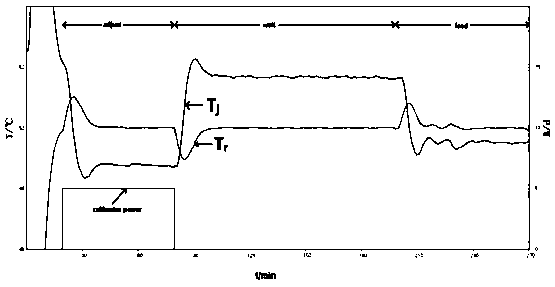

[0085] In this example, acetic anhydride is hydrolyzed to generate acetic acid as an example to illustrate the calorimetric test method of the present invention, and at the same time verify it with data recorded in literature. The feed molar ratio of acetic anhydride and water is 1:22.69, and the reaction temperature T r The temperature is 50°C, the material residence time is 20-30s, and the reaction pressure is 0.1 MPa.

[0086] experiment procedure:

[0087] 1) Air tightness test of the reaction system. Feed nitrogen into the reaction system through the gas replacement port, and control the nitrogen pressure through the decompression gauge. When the nitrogen gas reaches 3.0MPa, stop the nitrogen gas flow and start maintaining the pressure. If within 1 hour, the pressure drop of the reactor system is less than 0.01bar / min, it can be considered that the airtightness of the reaction system is good, and the pressure holding is over.

[0088] 2) Pressure relief. Open the sol...

Embodiment 3

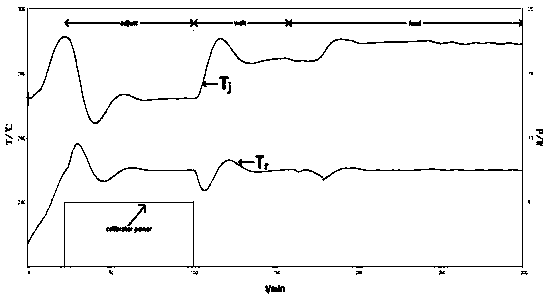

[0103] Present embodiment is with 40% methanol aqueous solution on solid catalyst (catalyst main component is CuO, ZnO, Al 2 o 3 、Na 2 O) take place under the catalysis to generate hydrogen and carbon dioxide as an example, the calorimetric test method of the present invention is described, and further verified by bond energy calculation. The 40% methanol aqueous solution enters at a flow rate of 0.0011g / s, the temperature of the 40% methanol aqueous solution before entering the reactor is 25°C, the reaction temperature is set at 250°C, the residence time of the material is 20-30s, and the reaction pressure is 1.5Mpa.

[0104] experiment procedure:

[0105] 1) Air tightness test of the reaction system. Feed nitrogen into the reaction system through the gas replacement port, and control the nitrogen pressure through the decompression gauge. When the nitrogen gas reaches 3.0MPa, stop the nitrogen gas flow and start maintaining the pressure. If within 1 hour, the pressure drop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com