Dynamic test device and method for cement-based material deformation in thermal curing process

A cement-based material, dynamic testing technology, used in electromagnetic measuring devices, electrical/magnetic solid deformation measurement, etc., can solve the problems of reading corrosion, can not eliminate errors, etc., achieve reasonable settings, easy operation, eliminate steam and temperature the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

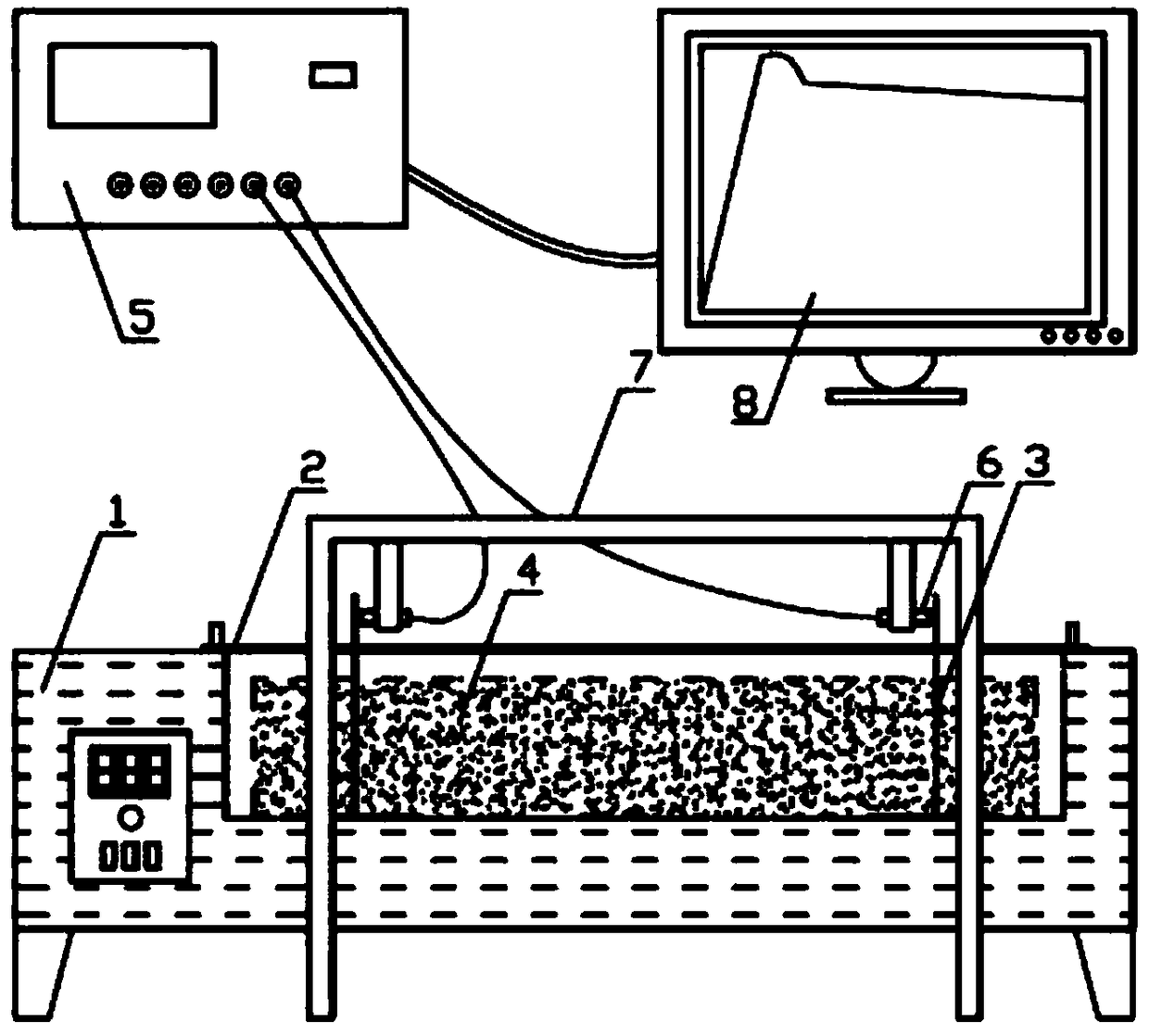

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

[0033] see as Figure 1-Figure 5As shown, the deformation dynamic testing device of a cement-based material in the thermal curing process described in this specific embodiment includes a controllable water bath heating system 1, a design mold system, an improved non-contact deformation measurement system and optimized data collection. Composed with analysis handlers. The controllable water bath heating system 1 is composed of a rectangular box made of 304 stainless steel and its double-layer insulation structure, heating liquid and temperature control program. The temperature control range is 20-100°C, and the temperature control accuracy is ±2°C. The heating rate is 0-20°C / h; three test mold slots are reserved, and when the three test molds are all installed, the liquid level of the heating liquid will rise to the top surface of the test mold side wall; the mold syst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Side wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com