Preparation method for diamond film on surface of harmonic reducer

A harmonic reducer, diamond film technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of poor thermal stability, low friction coefficient, high brittleness, etc., to achieve low wear rate, The effect of a low coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a diamond film on the surface of a harmonic reducer, comprising the steps of:

[0028] 1. First, use ultrasonic waves to perform acetone ultrasonic cleaning and ethanol ultrasonic cleaning on the surface of the harmonic reducer respectively. The temperature of ultrasonic cleaning is 50°C, and the ultrasonic time is 60 minutes.

[0029] 2. Then use ion bombardment to bombard the surface of the harmonic reducer, first place the harmonic reducer on the workpiece table in the vacuum chamber; the vacuum degree in the working room is pumped to 10 -3 After the Pa level, the working gas Ar was introduced, and the surface of the harmonic reducer was etched and cleaned by plasma bombardment. The ion cleaning time was 50 min and the voltage was 1000V to further remove impurities on the sample surface.

[0030] 3. Finally, argon gas is introduced into the vacuum chamber, and the physical vapor deposition method of ion beam enhanced deposition is adopted. Ar i...

Embodiment 2

[0032] A method for preparing a diamond film on the surface of a harmonic reducer, comprising the steps of:

[0033] 1. First, use ultrasonic waves to clean the surface of the harmonic reducer with acetone ultrasonic cleaning and ethanol ultrasonic cleaning respectively. The temperature of ultrasonic cleaning is 60°C, and the ultrasonic time is 40 minutes.

[0034] 2. Then use ion bombardment to bombard the surface of the harmonic reducer, first place the harmonic reducer on the workpiece table in the vacuum chamber; the vacuum degree in the working room is pumped to 10 -4 After the Pa level, the working gas Ar was introduced, and the surface of the harmonic reducer was etched and cleaned by plasma bombardment. The ion cleaning time was 40 min and the voltage was 1200V to further remove impurities on the sample surface.

[0035] 3. Finally, argon gas is introduced into the vacuum chamber, and the physical vapor deposition method of ion beam enhanced deposition is adopted. Ar i...

Embodiment 3

[0037] A method for preparing a diamond film on the surface of a harmonic reducer, comprising the steps of:

[0038] 1. First, use ultrasonic waves to perform acetone ultrasonic cleaning and ethanol ultrasonic cleaning on the surface of the harmonic reducer respectively. The temperature of ultrasonic cleaning is 60°C, and the ultrasonic time is 40 minutes.

[0039] 2. Then use ion bombardment to bombard the surface of the harmonic reducer, first place the harmonic reducer on the workpiece table in the vacuum chamber; the vacuum degree in the working room is pumped to 10 -3 After the Pa level, the working gas Ar was introduced, and the surface of the harmonic reducer was etched and cleaned by plasma bombardment. The ion cleaning time was 50 min and the voltage was 900V to further remove impurities on the sample surface.

[0040] 3. Finally, argon gas is introduced into the vacuum chamber, and the physical vapor deposition method of ion beam enhanced deposition is adopted. Ar io...

PUM

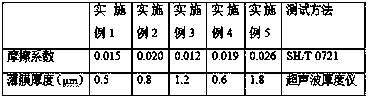

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com