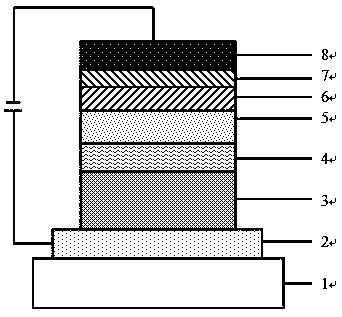

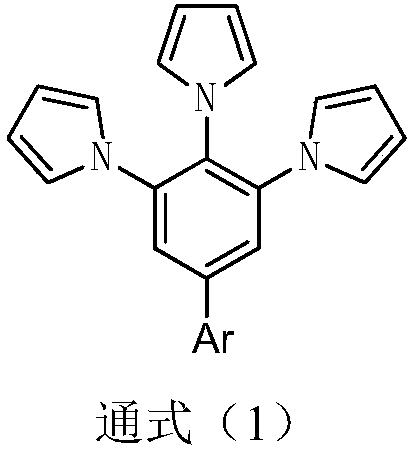

Preparation and application of novel umbrella-type light-emitting material with pyrrole structure

A luminescent material, pyrrole technology, applied in organic chemistry, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of luminous efficiency and service life that cannot satisfy device manufacturers, achieve good industrialization prospects, improve efficiency, reduce The effect of drive voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

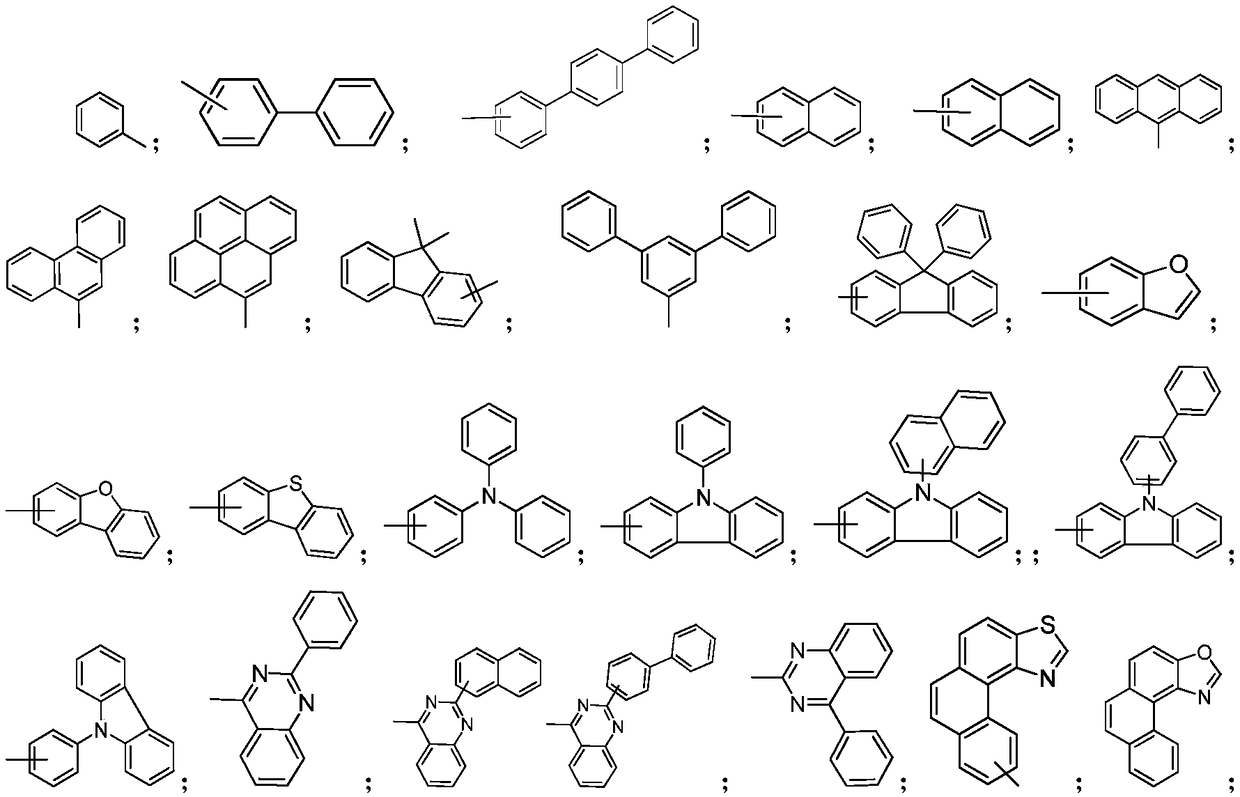

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: the synthesis of intermediate

[0025]

[0026] In a 1000ml three-necked flask, add 40.0g of raw material A (303mmol) and 62.9g of raw material B (939mmol) under the condition of nitrogen gas, add 167g of K2CO3 (1210mmol), 400ml of NMP, heat up to 160 ℃ ~ 170 ℃, keep warm for 15h, TLC Detect that the reaction of the raw materials is complete; cool down to room temperature, filter, rinse the filter cake with NMP, remove the solvent, pass the filtrate through a silica gel column, and rotate the column solution under reduced pressure. Recrystallized with toluene to obtain 68 g of white substance C with a yield of 82.2% and a purity of 98% by HPLC. The molar ratio of the raw material A to the raw material B is 1:3.1, and the molar ratio of the raw material A to K2CO3 is 1:4

[0027] In a 1000ml three-necked flask, under nitrogen gas flow, add 60g of Substance C (219mmol), add 600ml of dichloroethane, and lower the temperature to 0-5°C. Then elemental brom...

Embodiment 2

[0029] Embodiment 2: the synthesis of compound 1

[0030]

[0031] The specific synthetic route of compound 1

[0032]

[0033] Under the protection of nitrogen, weigh 45g of intermediate I (127.7mmol), 31.6g of raw material D (127.7mmol), 33.8g of sodium carbonate (319mmol), 62g of ethanol, 78.8g of water (78.8ml), 143.4mg of Pd (OAC) 2 (0.638mmol), 608mgX-phos (1.28mmol), stirred and mixed with toluene, heated to 85-90°C, refluxed for 5-10 hours, sampling and pointing the plate, it showed that there was no intermediate 1 remaining, and the reaction was complete; naturally cooled to Filter at room temperature, pass the filtrate through a silica gel column, and rotary evaporate the column solution under reduced pressure until there is no fraction. The crude product is a gray solid, which is refined with toluene and dried to obtain 47g of compound 1. Yield: 77.3%, HPLC: 99.9%, HPLC-MS: The theoretical molecular weight of compound 1 is 475.5, and the actual detection resu...

Embodiment 3

[0034] Embodiment 3: the synthesis of compound 5

[0035]

[0036] The specific synthetic route of compound 5

[0037]

[0038] Under the protection of nitrogen, weigh 50g intermediate I (141.95mmol), sodium carbonate 37.61g (354.88mmol), water 87ml, catalyst 318.7mg Pd(OAC) 2 (1.42mmol), 1350mg X-phos (2.84mmol). After the addition of the materials, mix them evenly with toluene, heat to 90-100°C, add the THF solution of the raw materials E dropwise at this temperature (weigh 33.1g (156.2mmol) of the raw materials E in a 500ml Erlenmeyer flask, and mix them with tetrahydrofuran uniform to clear). Control the temperature at 90-100°C and add dropwise. After the dropwise addition is completed, keep warm and reflux at 90-100°C. The sampling plate shows that there is no intermediate remaining, and the reaction is complete. After washing the organic phase with water and drying it, it was passed through a silica gel column, and the column liquid was desolvated under reduced ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com