Homogeneous phase ionic liquid catalyzed high-purity diethyl carbonate synthesizing technology

A technology of diethyl carbonate and ionic liquid is applied in the field of homogeneous ionic liquid catalyzed high-purity diethyl carbonate synthesis process, which can solve the problems of difficult separation of product and catalyst, high production cost, complicated process, etc., and achieve broad market application. Prospects, efficient production, the effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

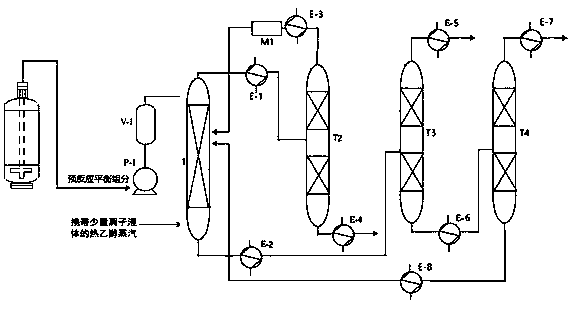

[0076] The first reactive distillation column T1: column diameter 1000mm; column height 19000mm; the number of plates in the public rectification section, initial distillation section, side line section, and public stripping section are 10, 20, 30, 15 respectively; the internal pressure of the column is 0.5 MPa; tower top temperature 130°C; tower bottom temperature of common stripping section 190°C; tower bottom temperature of side line section 170°C.

[0077] Atmospheric distillation column T2: column diameter 4000mm; column height 50000mm; the number of plates in the public rectification section, initial distillation section, and public stripping section are 10, 20, and 15 respectively; the pressure inside the column is 0.1MPa, and the temperature at the top of the column is 65 °C, the bottom temperature of the common stripping section is 120 °C.

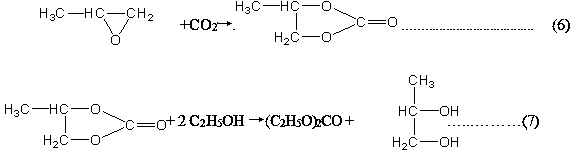

[0078] The molar ratio of raw material ethylene carbonate to ethanol is 10:1, the amount of ionic liquid acetate catalyst is 0.3...

Embodiment 2

[0081] Vacuum distillation tower T3: tower diameter 3000mm; tower height 40000mm; the number of plates in the public rectification section, initial distillation section, side line section, and public stripping section are 10, 20, 30, 15 respectively; the pressure inside the tower is 0.1 MPa The temperature at the top of the tower is 90°C, and the temperature at the bottom of the common stripping section is 160°C; the temperature at the bottom of the side line section is 120°C.

[0082] Vacuum distillation tower T4: tower diameter 3000mm; tower height 40000mm; the number of plates in the public rectification section, initial distillation section, side line section and public stripping section are 10, 20, 30, 15 respectively; the pressure inside the tower is 0.1 MPa ; The temperature at the top of the tower is 165°C, and the temperature at the bottom of the common stripping section is 180°C; the temperature at the bottom of the side line section is 150°C.

[0083] In the first r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com