Molecular sieve based catalyst and preparation method thereof as well as application to side chain alkylation reaction of methyl alcohol and methylbenzene

A catalyst and molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low catalyst life, low selectivity to styrene, etc., achieve simple preparation process and improve technical economy. and promotion possibilities, the effect of high methanol conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

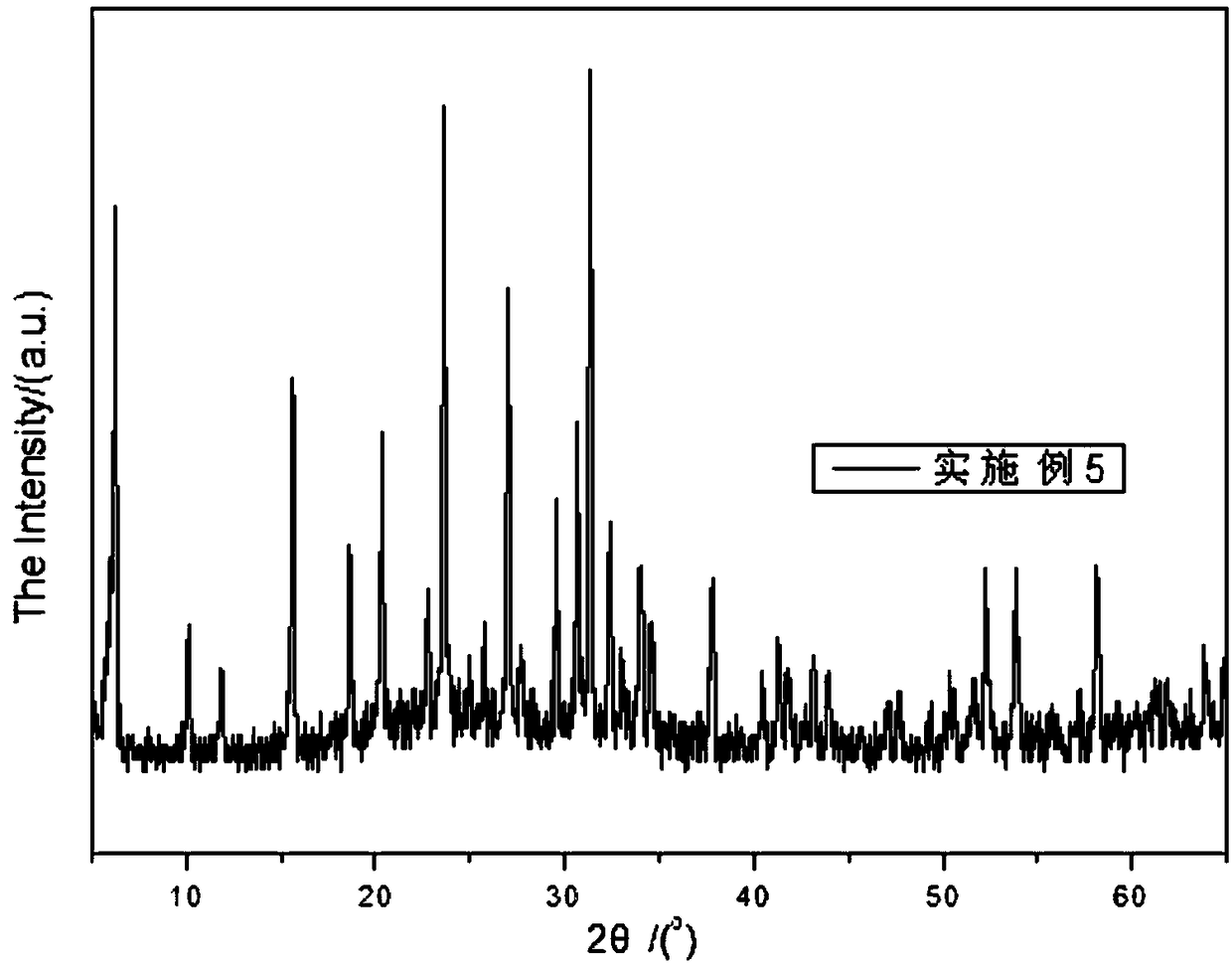

Image

Examples

preparation example Construction

[0025] According to an exemplary embodiment of the present invention, the preparation method of the molecular sieve catalyst includes the following steps.

[0026] Step A:

[0027] adding water source to the silicon source for dilution, then adding template agent, aluminum source and sodium source successively and stirring evenly after each addition to obtain a liquid mixture;

[0028] In this step, SiO 2 Calculated, the quality of the silicon source is 100%, and the silicon source can be one or more of sodium silicate, silica sol, methyl orthosilicate and ethyl orthosilicate. Take Al 2 o 3 Calculated, the mass of the aluminum source is SiO in the silicon source 2 56.56-84.84% of the mass, and the aluminum source can be one or more of aluminum isopropoxide, sodium metaaluminate and aluminum nitrate. Take Na 2 In terms of O, the mass of the sodium source is SiO in the silicon source 2 1 to 3 times the mass, and the sodium source can be one or a mixture of sodium hydroxid...

Embodiment 1

[0050] The raw material components of the molecular sieve catalyst of the present embodiment are (the unit is mass, if there is no special instruction, the following are all equivalent):

[0051] SiO 2 In total, weigh 100 parts of silica sol; 2 o 3 In total, 56.56 parts of aluminum isopropoxide, as Na 2 In terms of O, 200 parts of sodium hydroxide; in terms of H 2 In terms of O, 1200 parts of deionized water; 40 parts of template agent ethylenediamine, 1 part of trimethylsilyl chloride, alkali metal ion exchange solution is 0.5mol / L of KNO 3 solution.

[0052] The molecular sieve catalyst of the present embodiment is prepared by the following method from the above-mentioned component raw materials:

[0053] A) According to the above component ratio, add deionized water to the silica sol to dissolve and dilute, then add ethylenediamine, dissolve and stir evenly, then add aluminum isopropoxide dropwise, and finally add sodium hydroxide dropwise;

[0054] B) Stir the obtain...

Embodiment 2

[0060] The raw material components of the molecular sieve catalyst of the present embodiment are:

[0061] SiO 2 In total, weigh 100 parts of ethyl orthosilicate; 2 o 3 In total, 56.56 parts of aluminum isopropoxide; 2 In terms of O, 100 parts of sodium hydroxide; in terms of H 2 O meter, deionized water is 1600 parts; template agent butanediamine 40 parts, dimethyldimethoxysilane 20 parts, alkali metal ion exchange solution is 2mol / L CsNO 3 solution.

[0062] The molecular sieve catalyst of the present embodiment is prepared by the following method from the above-mentioned component raw materials:

[0063] A) According to the above component ratio, add deionized water to tetraethyl orthosilicate to dissolve and dilute, then add butanediamine, dissolve and stir evenly, then add aluminum isopropoxide dropwise, and finally add sodium hydroxide dropwise;

[0064] B) Stir the obtained liquid mixture evenly, age at room temperature for 6 hours, add dimethyldimethoxysilane and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com