A kind of methanol-to-olefins method

A technology for producing olefins and methanol from methanol is used in the production of hydrocarbons from oxygen-containing organic compounds, ethylene production, organic chemistry, etc. The effect of methanol conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

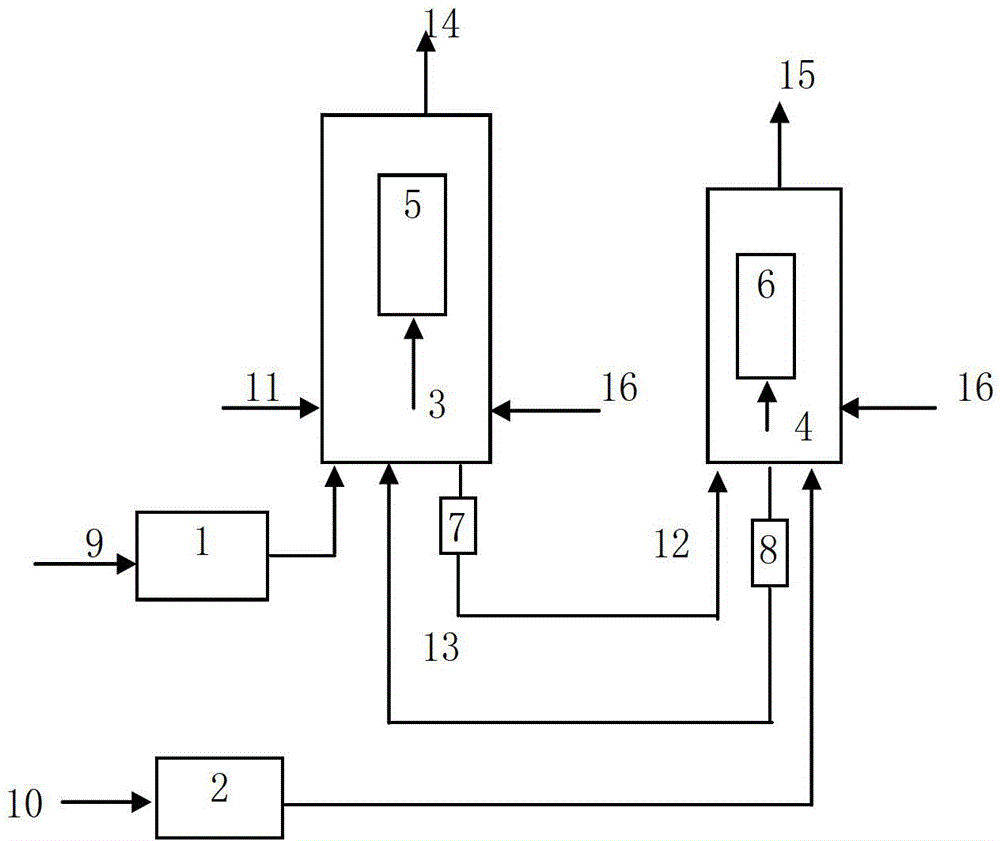

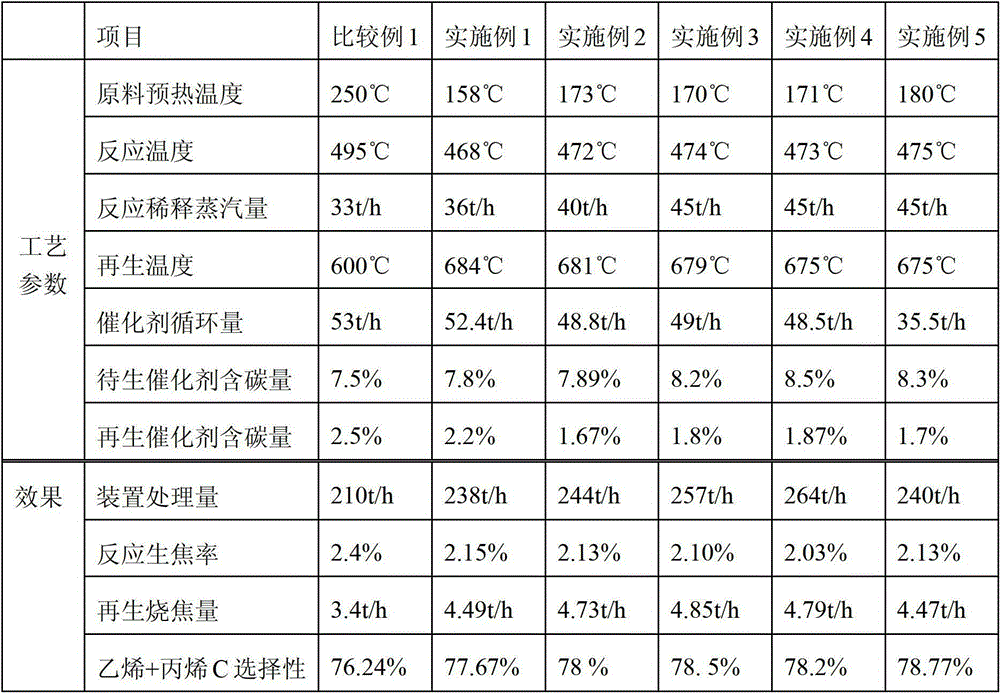

[0104] Such as figure 1 It shows that methanol 11 is preheated to 160°C through the feed system and mixed with about 50t / h of dilution steam before entering the reactor 3, and the product gas generated under the condition of 475°C in contact with the catalyst in the reactor enters the reaction cyclone separator 5. The product gas 14 after separating the catalyst enters the water washing and cooling system; as the reaction proceeds, the activity of the catalyst after the reaction decreases, and 35.5t / h of catalyst with a carbon content of 8% is controlled by the standby slide valve 7 and enters the regenerator 4. In the regenerator, it is in contact with the main air 10 from the auxiliary combustion chamber 2 and burned at 675°C. The generated flue gas enters the regenerative cyclone separator, and the flue gas 15 after separating the catalyst enters the waste heat recovery system; through the regeneration slide valve 8 Control 35.5t / h carbon content of 1.6% regenerated catalys...

Embodiment 2

[0106] Same as Example 1, except that the operation scheme is carried out according to the parameters listed in Table 2.

Embodiment 3

[0108] Same as Example 1, except that the operation scheme is carried out according to the parameters listed in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com