A kind of fish cake processing method using tuna fish meat as raw material

A processing method, tuna technology, applied in food ingredients as taste improvers, food ingredients, food science, etc., can solve the problems of fishy and sour taste, low elasticity, poor gel performance of tuna kamaboko, etc., to eliminate sourness taste and fishy smell, uniform and bright color, and soft texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

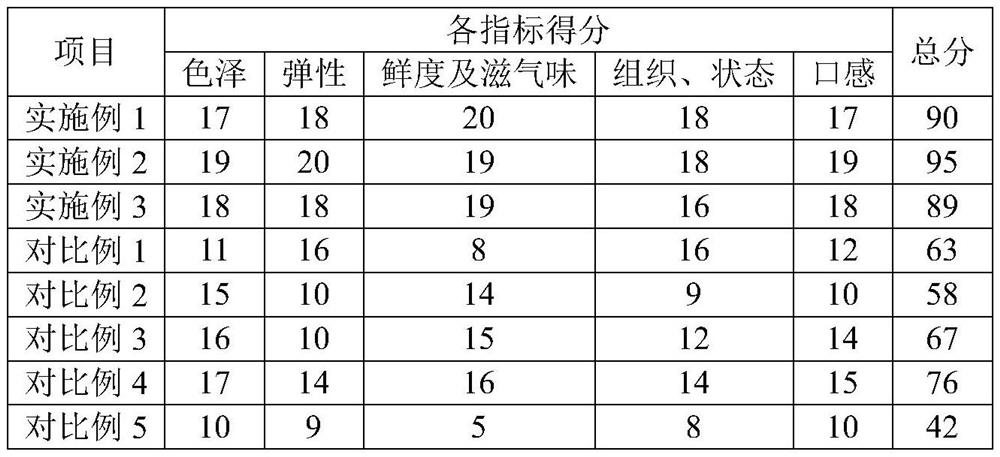

Embodiment 1

[0030] A kind of fish cake processing method taking tuna fish meat as raw material, comprises the following steps:

[0031](1) Take the tuna and remove the scales, viscera, head and fish skin, pick the fish meat, grind it, then rinse and deacidify, drain; the process of rinsing and deacidification is as follows: add calcined clam shells to the baking soda solution with a concentration of 1wt%. Powder, EDTA, vitamin E and chitosan oligosaccharides are evenly dispersed, and the dispersion concentrations are 4wt%, 0.1wt%, 0.3wt% and 0.5wt%, respectively. Add tuna fish meat for soaking, and the mass volume ratio of tuna fish meat and baking soda solution is 1:1 , soaking temperature 2°C, time 60min, rinse with water after soaking until there is no calcined clam shell powder on the surface of the fish, and the calcined clam shell powder used is obtained by calcining clean clam shells at 900°C for 4 hours and then crushing to 80 mesh; (2) The drained tuna flesh was crushed twice, ea...

Embodiment 2

[0036] A kind of fish cake processing method taking tuna fish meat as raw material, comprises the following steps:

[0037] (1) Take the tuna and remove the scales, viscera, head and fish skin, pick the fish meat, grind it, then rinse and deacidify, drain; rinse and deacidify as follows: add calcined clam shell powder to the baking soda solution with a concentration of 2wt%. , EDTA, vitamin E and chitosan oligosaccharides are uniformly dispersed, and the dispersion concentration is 2wt%, 0.2wt%, 0.4wt% and 0.6wt%, respectively, add tuna fish meat for soaking, the mass volume ratio of tuna fish meat and baking soda solution is 1:1.5, The soaking temperature is 5°C and the time is 75min. After soaking, rinse with water until there is no calcined clam shell powder on the surface of the fish meat. The calcined clam shell powder used is obtained by calcining clean clam shells at 950°C for 5 hours and then crushing to 100 mesh;

[0038] (2) beat the drained tuna flesh twice, beat ea...

Embodiment 3

[0044] A kind of fish cake processing method taking tuna fish meat as raw material, comprises the following steps:

[0045] (1) Take the tuna and remove the scales, viscera, head and fish skin, pick the fish meat, mince, rinse and deacidify, and drain; rinse and deacidify as follows: add calcined clam shells to the baking soda solution with a concentration of 1.5wt% Powder, EDTA, vitamin E and chitosan oligosaccharides are evenly dispersed, and the dispersion concentrations are 3wt%, 0.15wt%, 0.6wt% and 0.8wt%, respectively. Add tuna fish meat for soaking, and the mass volume ratio of tuna fish meat and baking soda solution is 1:2 , soaked at 8°C for 90 minutes, rinsed with water after soaking until there is no calcined clam shell powder on the surface of the fish, and the calcined clam shell powder used was obtained by calcining clean clam shells at 1000°C for 6 hours and then crushing to 100 mesh;

[0046] (2) beat the drained tuna flesh twice, beat each time for 4 minutes, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com