Preparation technology of composite semen coicis ultrafine powder

A preparation process, the technology of barley powder, which is applied in the field of food processing, can solve the problems of affecting the nutrition and taste of barley compound powder, the inability to obtain nutrient absorption, uneven mixing, etc., achieve high dispersion, inhibit blood sugar rise, and promote uniform mixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

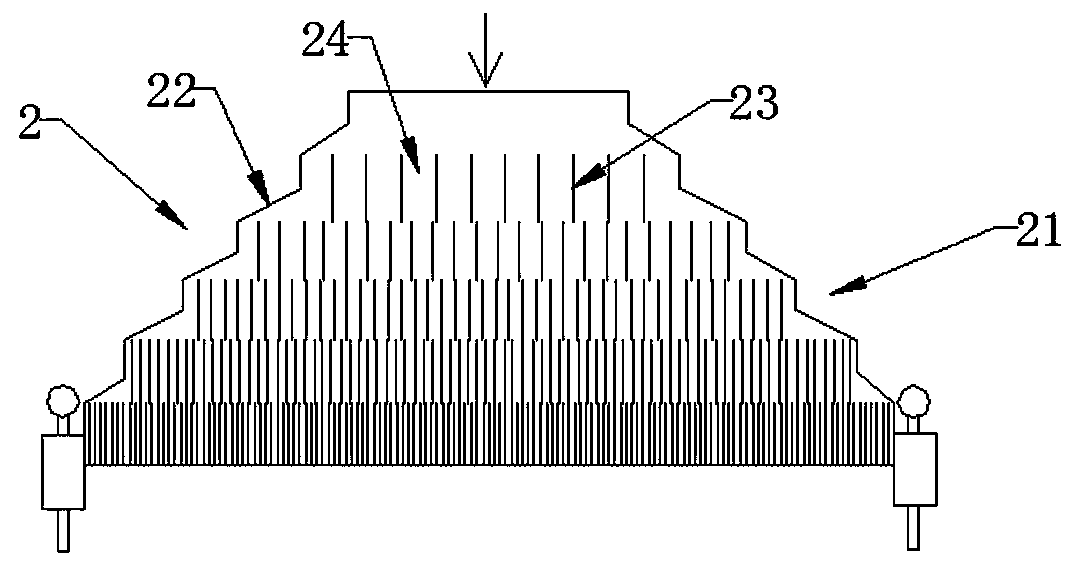

Image

Examples

Embodiment 1

[0036] A preparation process of compound barley superfine powder, specifically comprising the steps of:

[0037] S1. Place the dried and ripened barley and red beans in a milling machine for grinding, and grind the barley powder and red bean powder respectively until evenly. The particle size of the barley powder and red bean powder particles is 0.1cm; Red beans should be air-dried, dried and matured before grinding to reduce the water content of barley and red beans, so as to prevent excessive water content from causing powder agglomeration and affecting the grinding effect;

[0038] S2. Add edible organic acid to the barley powder and red bean powder for extraction, the edible organic acid is citric acid, and use acid treatment to remove the starch in the barley powder and red bean powder, the acid treatment time is 30min, and the temperature is 35 ℃; then add a degreasing agent to the acid-treated barley powder solution and red bean powder solution to carry out degreasing p...

Embodiment 2

[0047] A preparation process of compound barley superfine powder, specifically comprising the steps of:

[0048] S1. Place the dried and matured barley and red beans in a milling machine for grinding, and grind the barley powder and red bean powder to uniformity respectively. The particle size of the barley powder and red bean powder particles is 0.2cm; Red beans should be air-dried, dried and matured before grinding to reduce the water content of barley and red beans, so as to prevent excessive water content from causing powder agglomeration and affecting the grinding effect;

[0049] S2. Add edible organic acid to the barley powder and red bean powder for extraction, the edible organic acid is tartaric acid, and remove the starch in the barley powder and red bean powder by acid treatment, the acid treatment time is 40min, and the temperature is 45°C Then add degreasing agent in the barley powder solution and red bean powder solution after acid treatment and carry out degreas...

Embodiment 3

[0058] A preparation process of compound barley superfine powder, specifically comprising the steps of:

[0059] S1. Place the dried and ripened barley and red beans in a milling machine for grinding, and grind the barley powder and red bean powder respectively until evenly. The particle size of the barley powder and red bean powder particles is 0.1cm; Red beans should be air-dried, dried and matured before grinding to reduce the water content of barley and red beans, so as to prevent excessive water content from causing powder agglomeration and affecting the grinding effect;

[0060] S2. Add edible organic acid to the barley powder and red bean powder for leaching, the edible organic acid is one of citric acid or tartaric acid, use acid treatment to remove the starch in the barley powder and red bean powder, the acid treatment time for 35min, and the temperature is 40°C; then add a degreasing agent to the acid-treated barley powder solution and red bean powder solution for de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com