Fuel cell negative electrode catalyst and preparation method and application thereof

A fuel cell cathode and catalyst technology, applied in battery electrodes, nanotechnology for materials and surface science, circuits, etc., can solve the problems of time and energy consumption, high price, poor stability, etc., and achieve good methanol resistance and Stability, good catalytic performance, short time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] As introduced in the background technology, there are certain deficiencies in the catalytic performance of non-metallic catalysts in CN 108281679 A. In order to solve the above technical problems, the present disclosure proposes a method for preparing a fuel cell cathode catalyst, which includes the following steps:

[0030] Using 2-amino-terephthalic acid and iron salt as raw materials, the metal iron-organic framework material was prepared by solvothermal synthesis, and the metal iron-organic framework material was washed in N,N-dimethylformamide and filtered , drying the filtered precipitate to obtain a precursor, calcining the precursor at 550-650° C. under an inert gas atmosphere, and then performing acid treatment to obtain iron-nitrogen-doped carbon nanomaterials. Wherein, the solvent used in the solvothermal synthesis method is N,N-dimethylformamide.

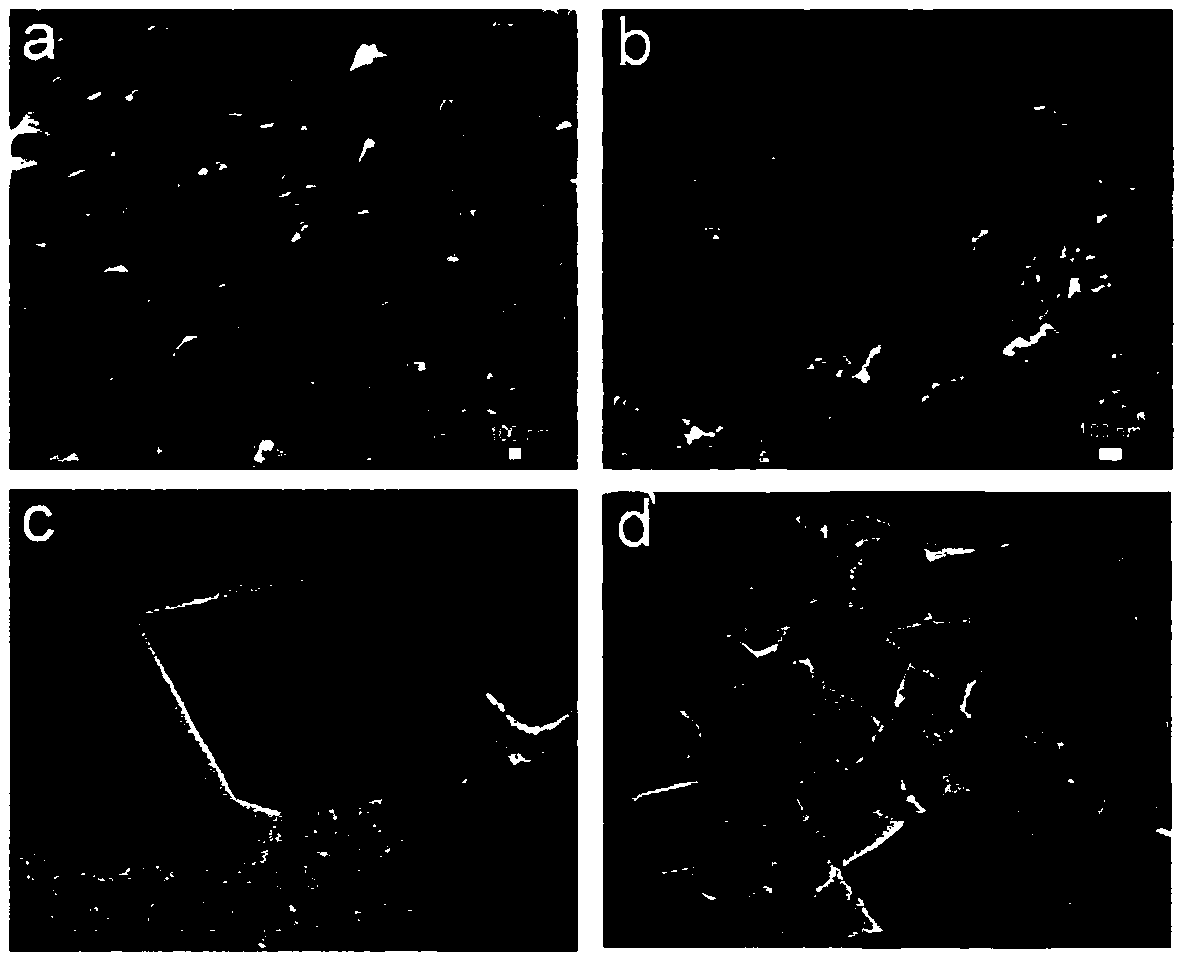

[0031] Different solvents were used in the solvothermal reaction to obtain different crystal morphologies. The...

Embodiment 1

[0052] A preparation method for nitrogen-iron-doped carbon nanomaterials, comprising the following steps:

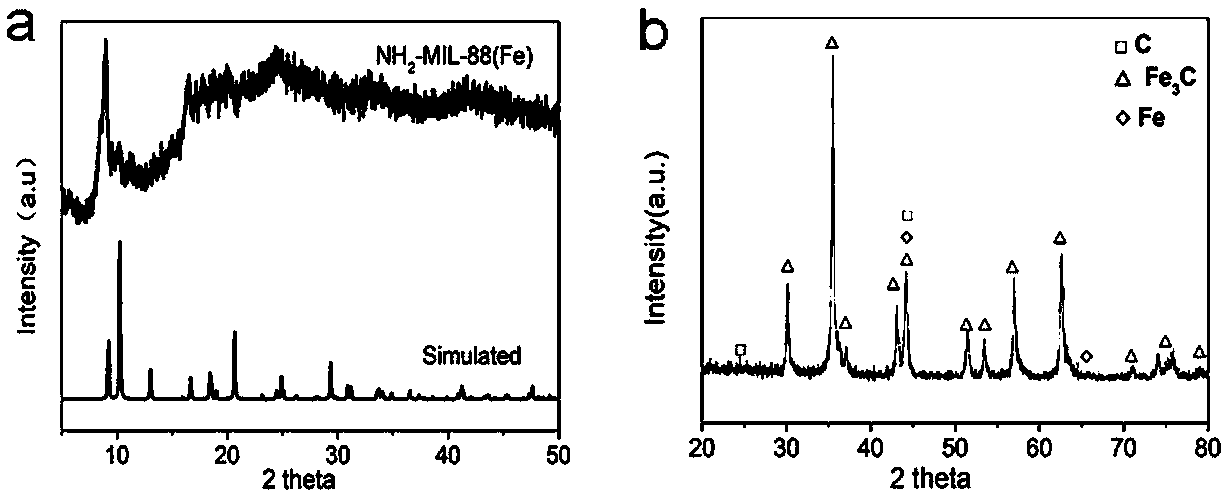

[0053] 1) Preparation of nanoscale metallic iron-organic framework material precursor: weigh 1.3838mmol 2-amino-1,4-terephthalic acid, and simultaneously weigh 1.3838mmol ferric chloride hexahydrate and dissolve it in 30mL N,N-di Methylformamide, stirred until fully dissolved, then added to a polytetrafluoroethylene reactor, sealed the reactor, reacted at 120°C for 20 hours, then cooled to room temperature, filtered the above reaction solution, and filtered the precipitate with N, N-dimethylformamide was washed three times, and then dried in a vacuum oven for 12 hours to obtain a brown-black powder product.

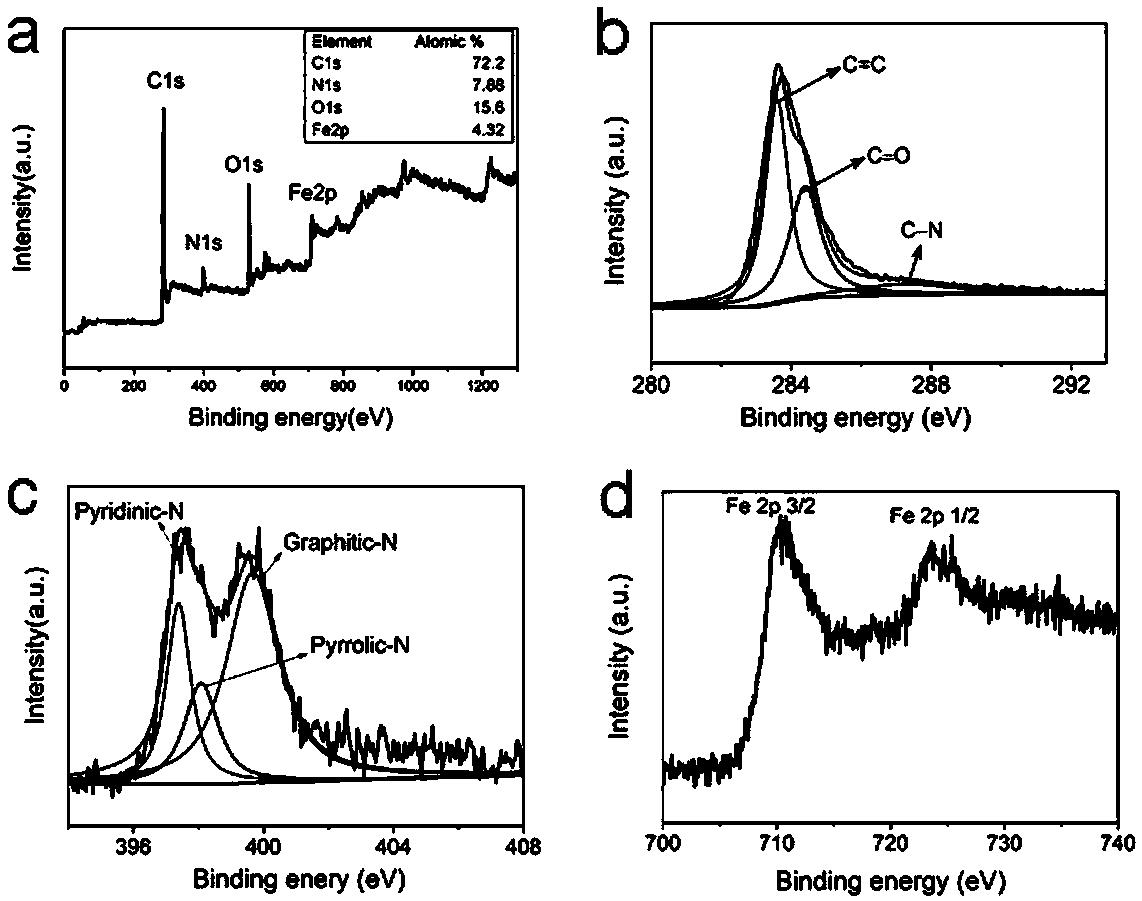

[0054] 2) Preparation of nitrogen-iron-doped carbon nanomaterials (N-C-Fe): put the nanoscale metallic iron-organic framework material precursor prepared in step 1) into a tube furnace, -1 The temperature was raised to 600 ° C at a certain rate, and the nitrogen-ir...

Embodiment 2

[0056] This example is the same as Example 1, the difference is that this example is heated at 3°C·min under an argon atmosphere. -1 The temperature was raised to 550 ° C at a certain rate, and the nitrogen-iron-doped carbon nanomaterial was obtained by roasting for 3 hours, and then treated with 2M hydrochloric acid, and the obtained material was named N-C-Fe-550.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Hole size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap