Preparation process of phosphorus-and-nitrogen-doped graphene porous carbon composite material

A composite material and preparation technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of unfavorable industrialization development and complicated experimental process, and achieve the improvement of electron transfer rate and electrochemical activity, preparation method Simple, energy-dense effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Dissolve 300mg o-phenylenediamine in 8.8mL deionized water, add 7mL graphene oxide (GO) solution (4.3mgmL -1 ) And ultrasonic for 30min, add 4.2mL phosphoric acid solution (2M) and continue ultrasonication for 30min, the obtained GO concentration is 1.5mg mL -1 .

[0035] Transfer the above solution to an autoclave and keep it at 90℃ for 6h. When it is cooled to room temperature, take out the reactant, place it in a 35℃ water bath, add 8.9mL of ferric chloride solution (1M), seal it and let it stand for 24h, and freeze-dry it. mixture.

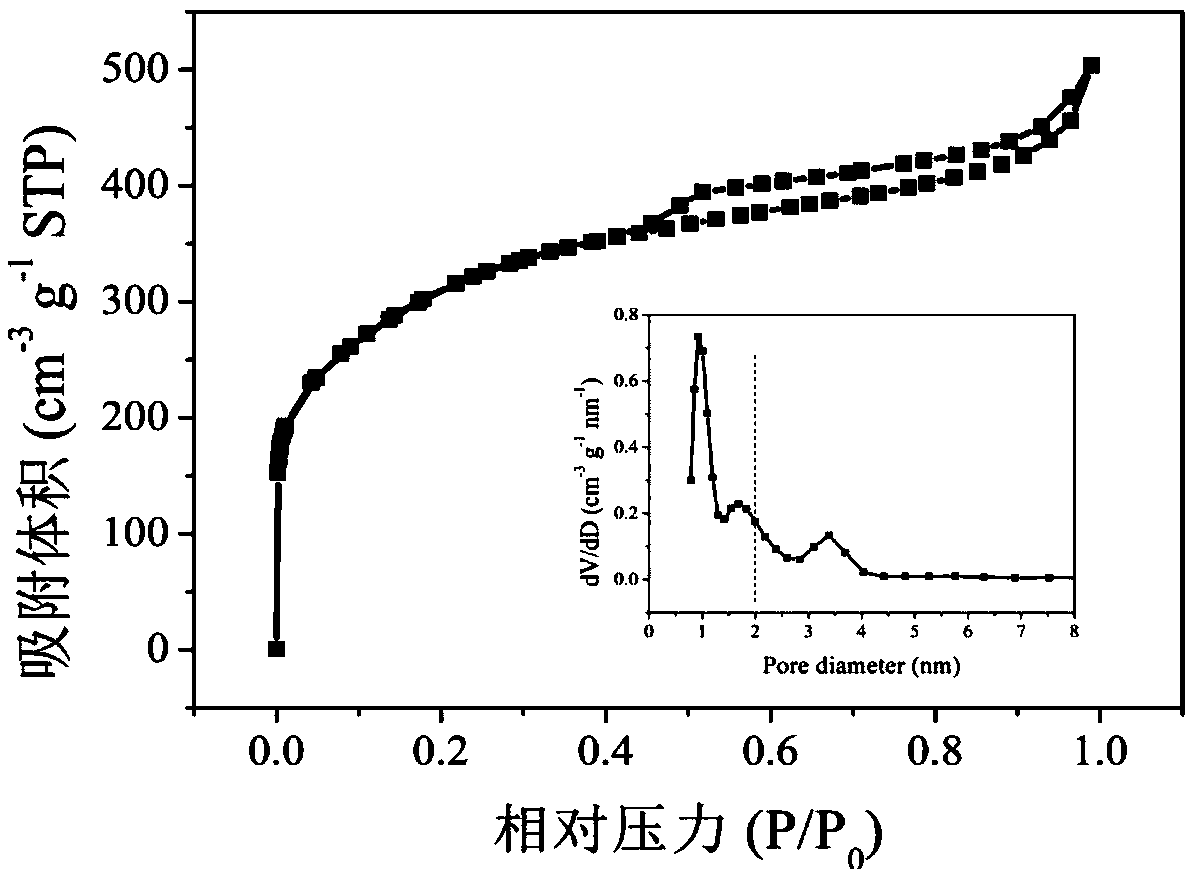

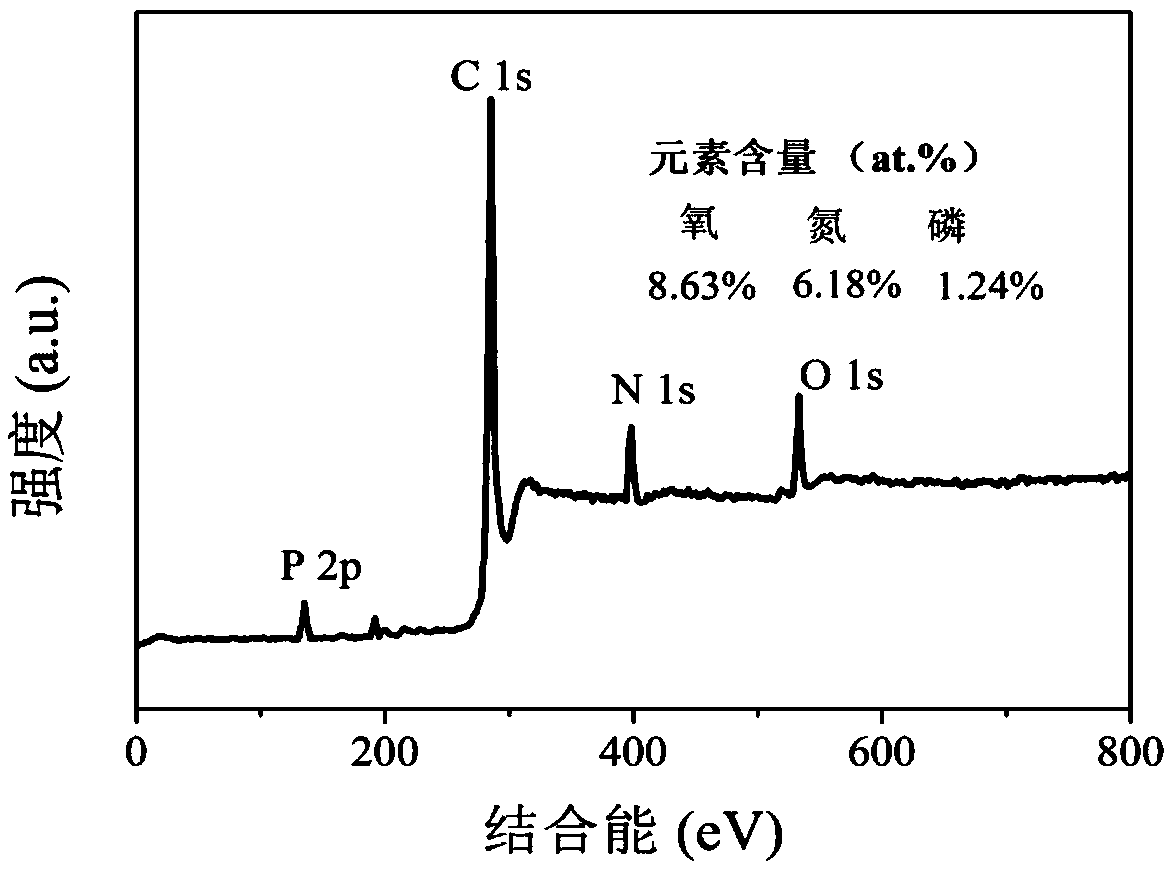

[0036] 3℃min in a nitrogen environment -1 The rate was raised to 800°C and kept for 2h. After the tube furnace was cooled to room temperature, the samples were collected, and then soaked in 1M hydrochloric acid solution, then washed, dried and passed through a 400 mesh sieve for use. The prepared phosphorus-nitrogen-doped graphene porous carbon composite material is washed and dried. After testing, its specific surface area is 1101.6m 2 g -...

Embodiment 2

[0044] The o-phenylenediamine, phosphoric acid and graphene oxide solution are subjected to hydrothermal reaction, ferric chloride polymerization and freeze drying. Weigh 2g of the obtained sample into a tube furnace and roast it at 700°C for 2h in a nitrogen atmosphere, soak and wash it in a 1M hydrochloric acid solution, then dry and pass through a 400 mesh sieve for use.

[0045] The commercial acetylene black, polytetrafluoroethylene, and phosphorus-nitrogen co-doped graphene porous carbon materials in a ratio of 1:1:8 are mixed uniformly, and a mixed solution of alcohol and water is added to make a slurry, and then evenly spread on 1 cm 2 The stainless steel net is dried and compacted at 20Mpa to prepare super capacitor electrodes.

[0046] After testing, the specific capacitance value of the prepared supercapacitor electrode material is 390F g -1 .

Embodiment 3

[0048] The o-phenylenediamine, phosphoric acid and graphene oxide solution are subjected to hydrothermal reaction, ferric chloride polymerization and freeze drying. Weigh 2g of the obtained sample and put it into a tube furnace in a nitrogen atmosphere to roast at 900°C for 2h, then wash with 1M hydrochloric acid, dry and pass through a 400 mesh sieve for use.

[0049] The commercial acetylene black, polytetrafluoroethylene, and phosphorus-nitrogen co-doped graphene porous carbon materials in a ratio of 1:1:8 are mixed uniformly, and a mixed solution of alcohol and water is added to make a slurry, and then evenly spread on 1 cm 2 The stainless steel net is dried and compacted at 20Mpa to prepare super capacitor electrodes.

[0050] After testing, the specific capacitance value of the prepared supercapacitor electrode material is 274F g -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com