Inductance detecting device after film cracking of ferrites coating

A detection device and ferrite technology, which is applied in measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve the problems of high labor intensity, low detection efficiency, and affecting production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments involved in the present invention will be described in further detail below in conjunction with the accompanying drawings.

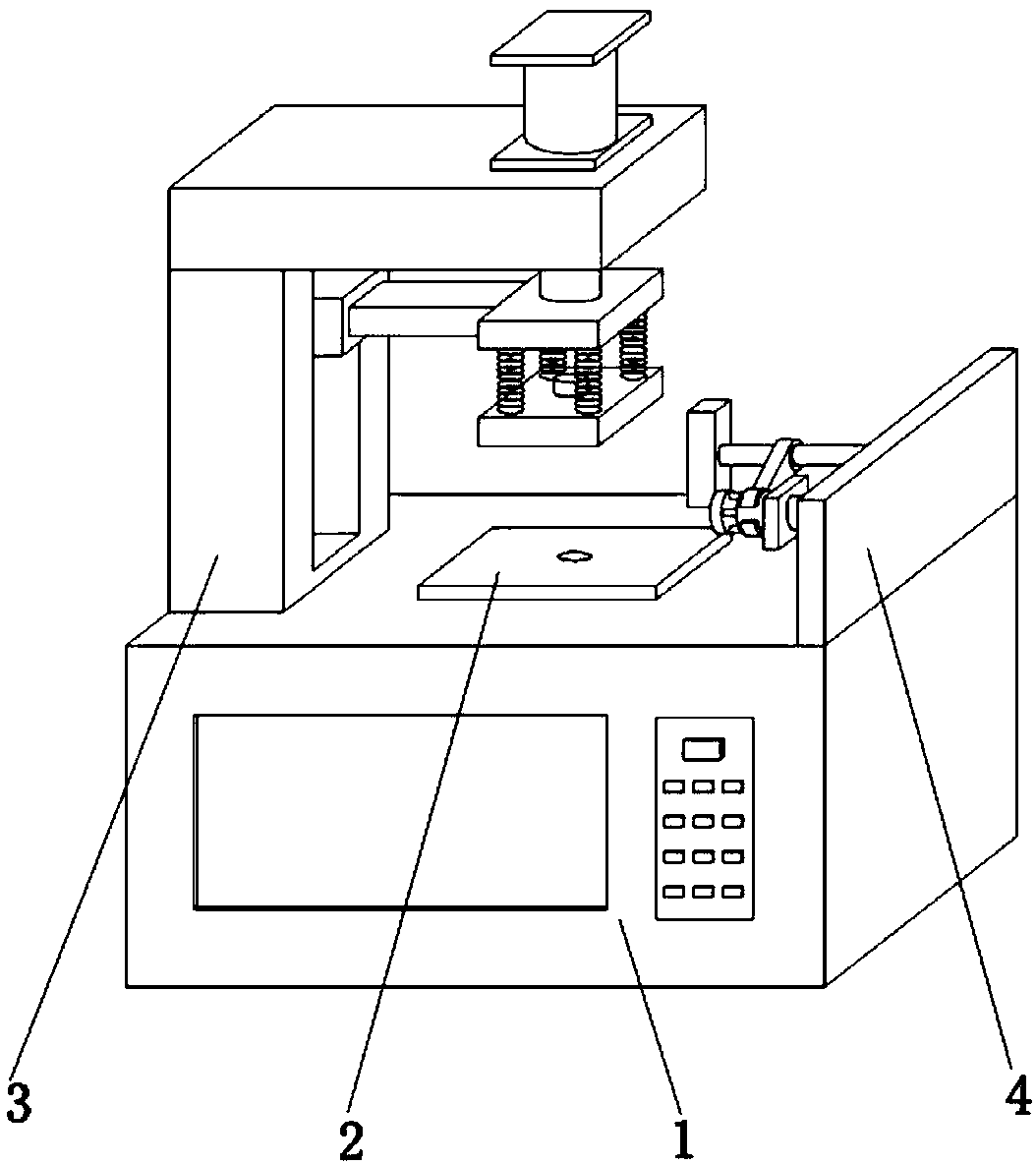

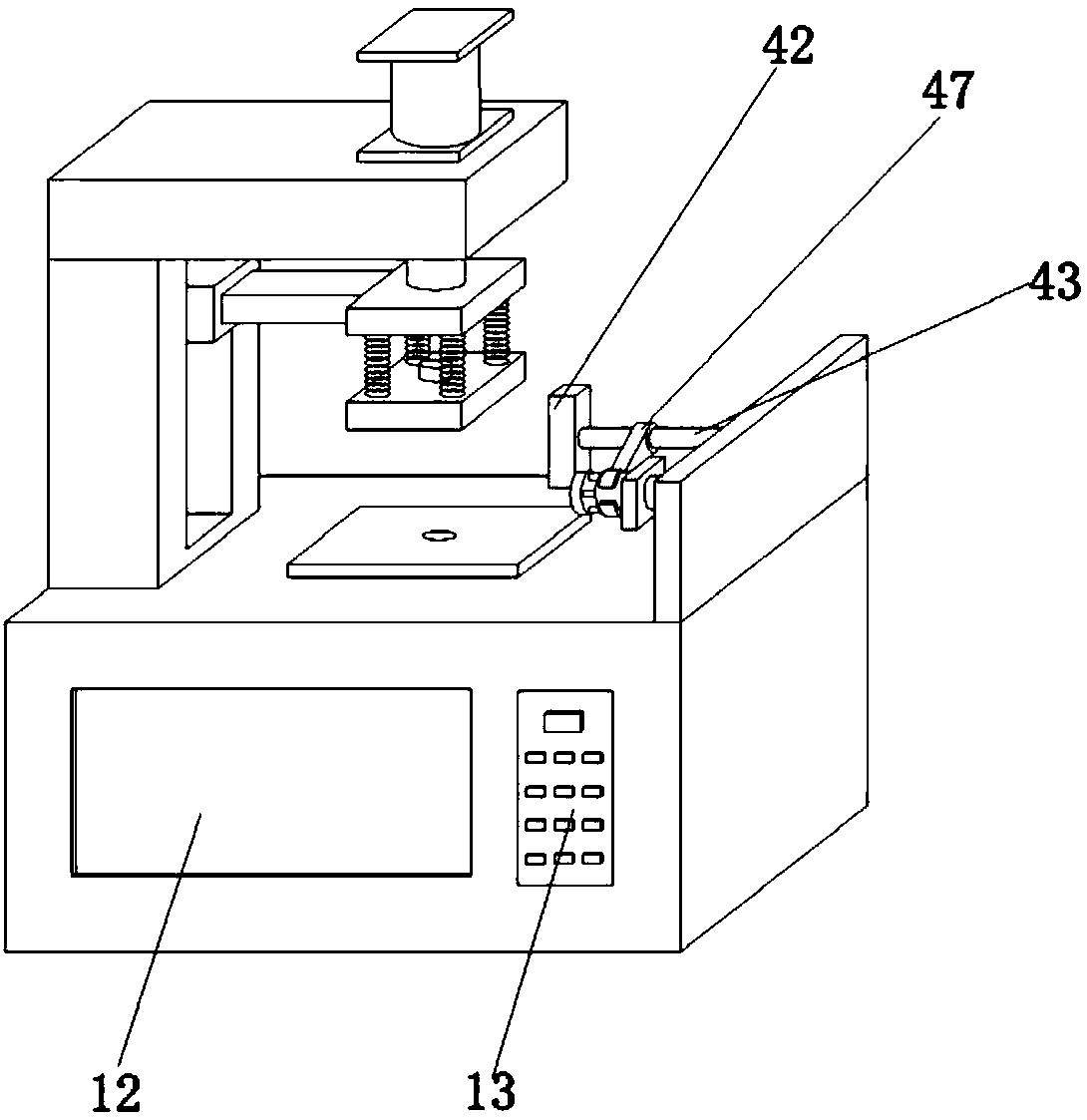

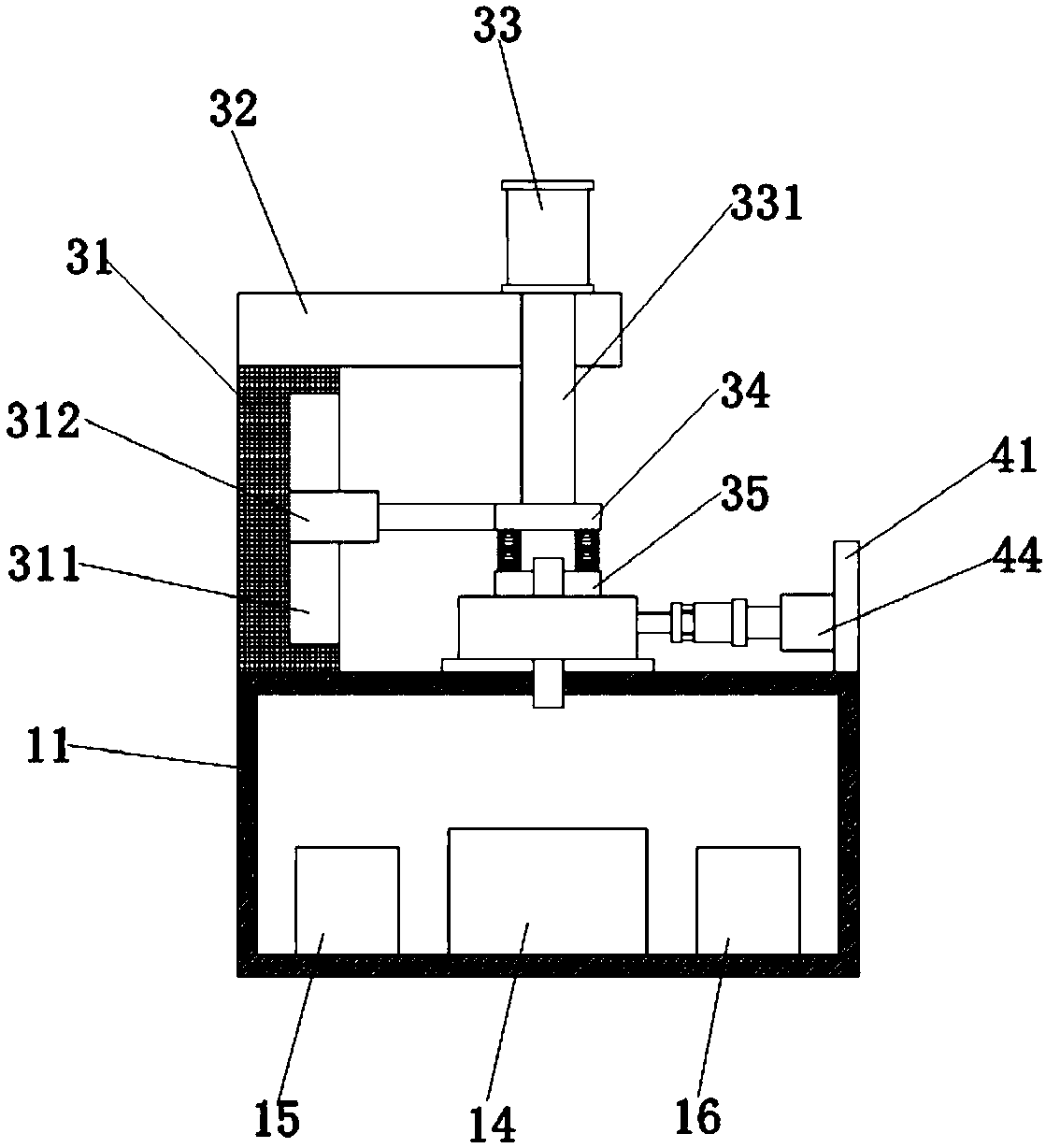

[0025] combine Figure 1 to Figure 5, an inductance detection device after ferrite coating is crushed, including a device body, the device body includes a control box 1, a loading base 2, a detection mechanism 3 and a marking mechanism 4, and the loading base 2 is located in the center of the control box 1, ferrite 5 is placed on the top of the loading base 2, the detection mechanism 3 is located on one side of the top of the control box 1, and the marking mechanism 4 is located on the other side of the top of the control box 1; the control box 1 includes a box body 11, Liquid crystal display 12, control panel 13, control module 14, button module 15 and inductance measurement module 16, liquid crystal display 12 and control panel 13 are positioned at the front of casing 11, control module 14, button module 15 and inductance measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com