Novel drying filter and preparation method thereof

A filter and drying technology, applied in chemical instruments and methods, separation methods, dispersed particle filtration, etc., can solve the problems of increasing the manufacturing cost of drying filters, complicated processing technology of drying filters, polluting the working environment of workers, etc. The parts are clean and beautiful, the energy consumption is reduced, and the working environment is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

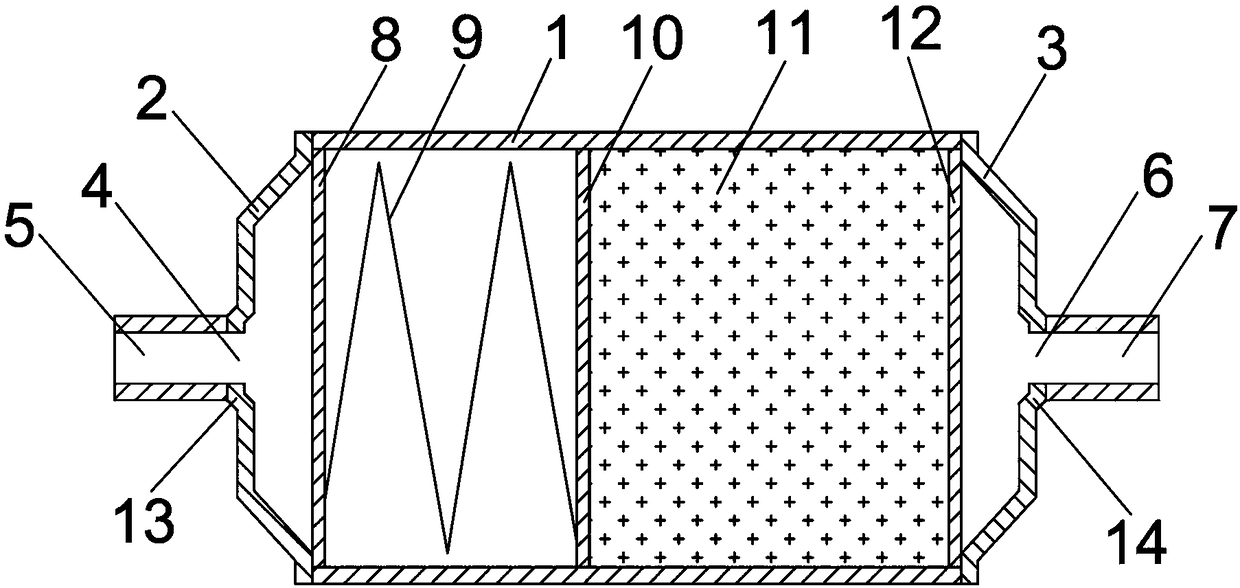

[0022] Embodiment 1: as figure 2 As shown, it includes a cylinder body, a left end cap and a right end cap. The left end cap and the right end cap are respectively arranged on both sides of the cylinder body. The diameters of the left end cap and the right end cap are slightly larger than the outer diameter of the cylinder body, so The center of the left end cover is provided with an air intake hole, and the edge of the air intake hole is provided with a first connecting portion, the first connecting portion is a first protruding ring stamped from the edge of the air intake hole, the first protruding ring The outer surface is welded with an air inlet pipe, and the air inlet pipe is coaxial with the air inlet hole, and the center of the right end cover is provided with an air outlet hole, and the edge of the air outlet hole is provided with a second connecting part, and the second connecting part is the edge of the air outlet hole The second protruding ring is punched, the out...

Embodiment 2

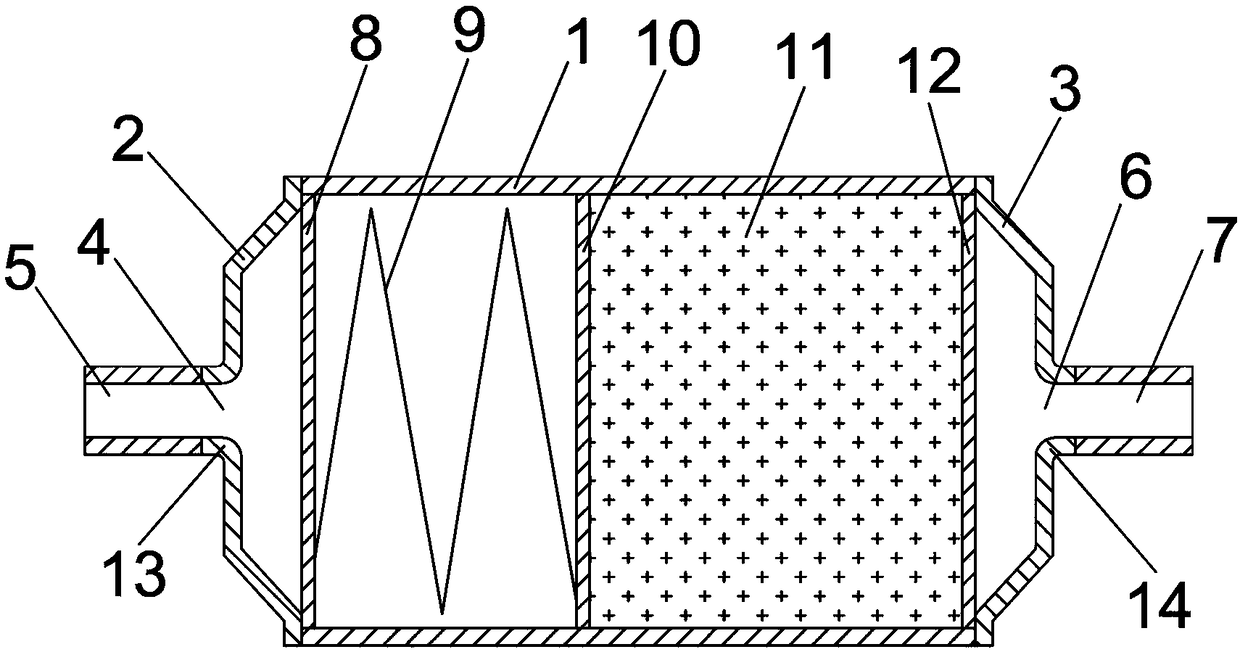

[0031] Example 2, such as image 3 As shown, it includes a cylinder body, a left end cap and a right end cap. The left end cap and the right end cap are respectively arranged on both sides of the cylinder body. The diameters of the left end cap and the right end cap are slightly larger than the outer diameter of the cylinder body, so The center of the left end cover is provided with an air intake hole, and the edge of the air intake hole is provided with a first connecting portion, the first connecting portion is a first flanging formed by flanging outward at 90° from the edge of the air intake hole, and the The first flanging is welded with an air inlet pipe, and the air inlet pipe is coaxial with the air inlet hole, and the center of the right end cover is provided with an air outlet hole, and the edge of the air outlet hole is provided with a second connection part, which is the outlet The second flanging formed by the 90° outward flanging of the air hole edge, the second f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com