Pneumatic diving pump and use method thereof

A technology for pneumatic submersible pumps and water pumps, which is applied to pumps, pump devices, non-variable-capacity pumps, etc., can solve the problems of insufficiently optimized fan blade structure design, low aerodynamic efficiency, and short service life, etc. The effect of convenient assembly, high work efficiency and strong sewage discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

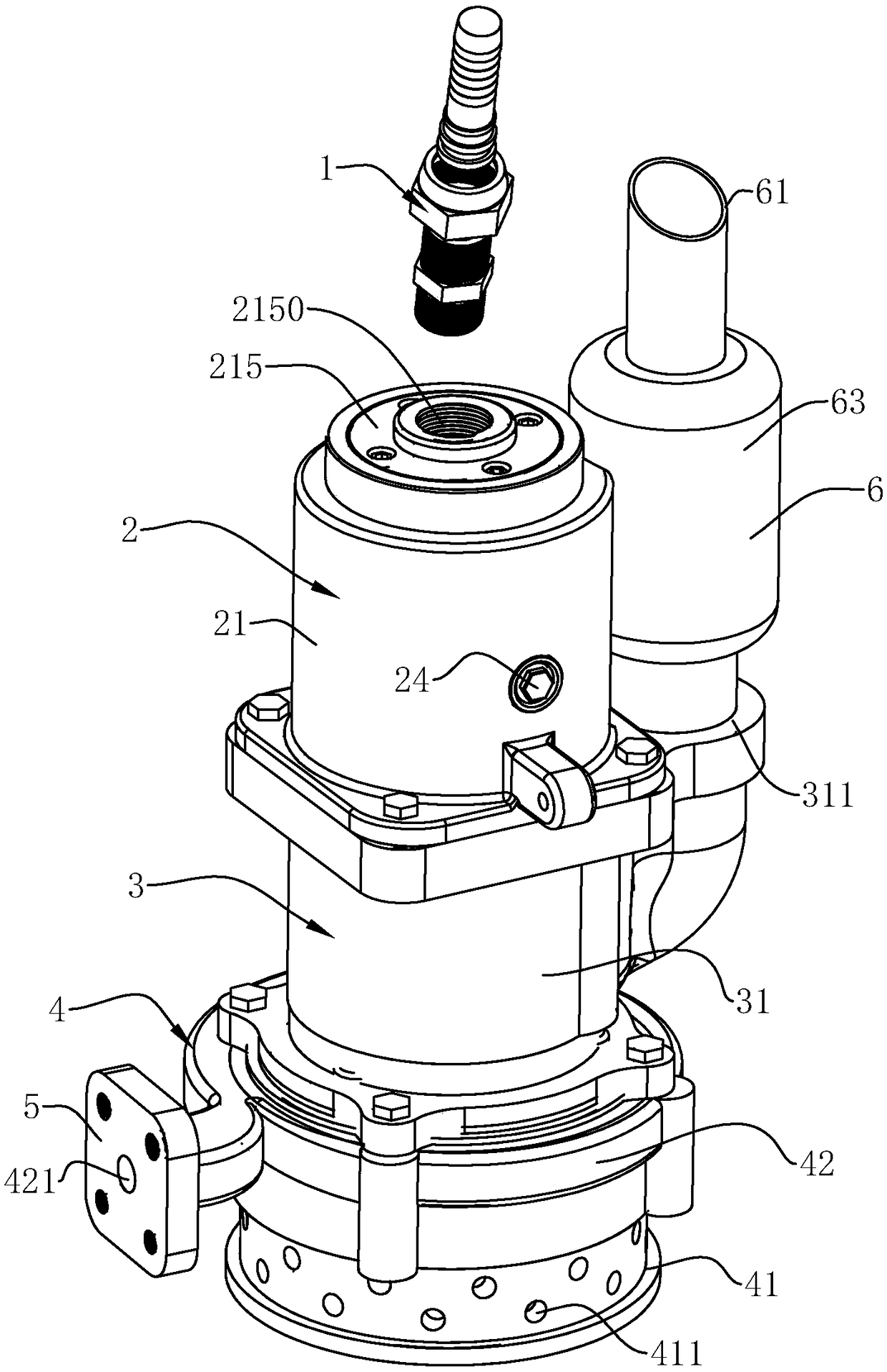

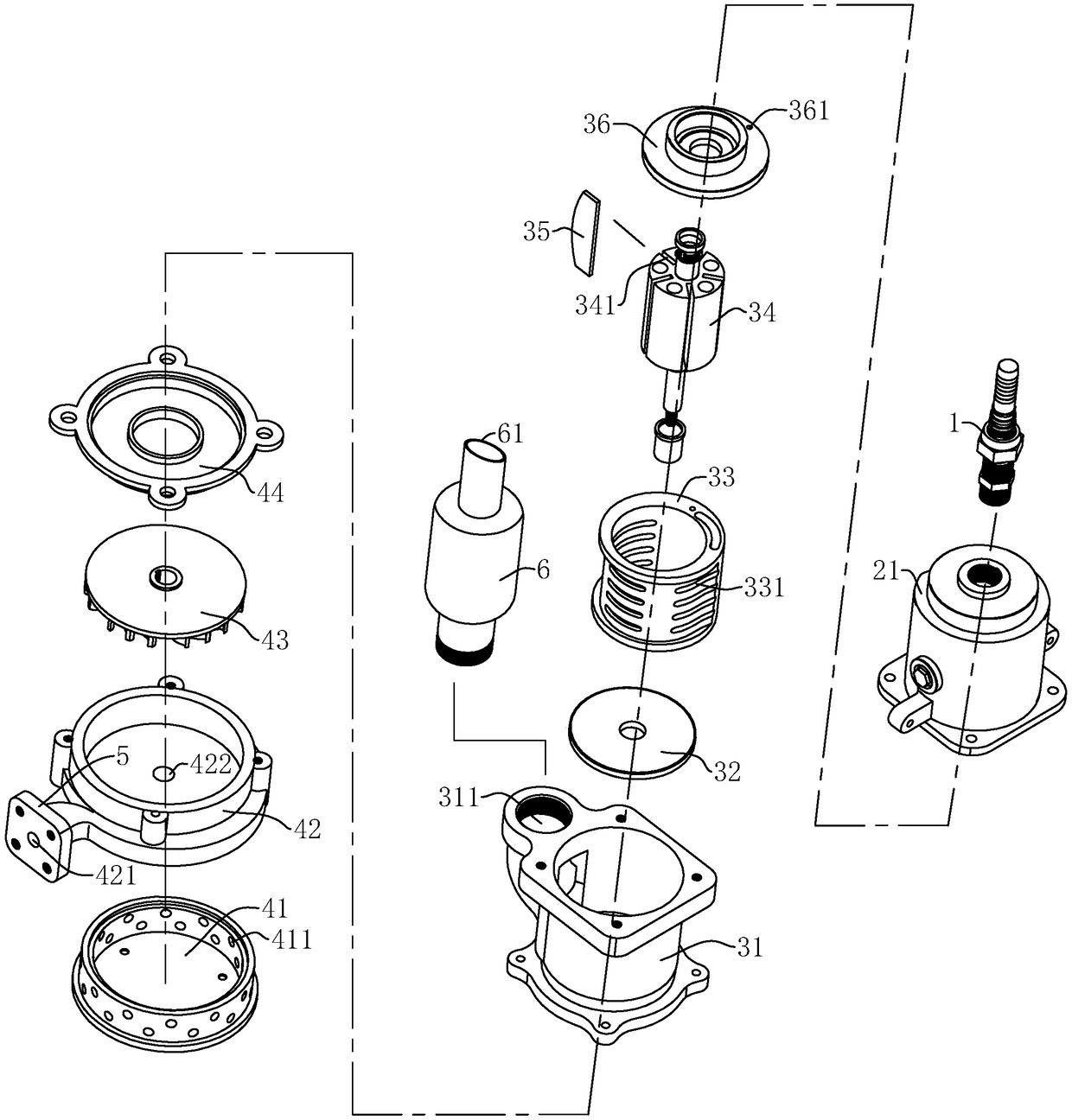

[0038] A kind of pneumatic submersible pump, refer to figure 1 and figure 2 As shown, it includes an air pipe joint 1 for connecting to an external air source, a lubricator 2 connected to the air pipe joint 1, connected under the lubricator 2 to receive the air source and atomized oil, and used to convert the air source to rotation A powered air motor 3, a water pump body 4 connected to the power output end of the air motor 3 and having a water inlet 422, a drain connector 5 connected to the output end of the water pump body 4, and a muffler 6 connected to the exhaust port 311 of the air motor 3. For the external air source, it can be generated by an air pump or an air source generator.

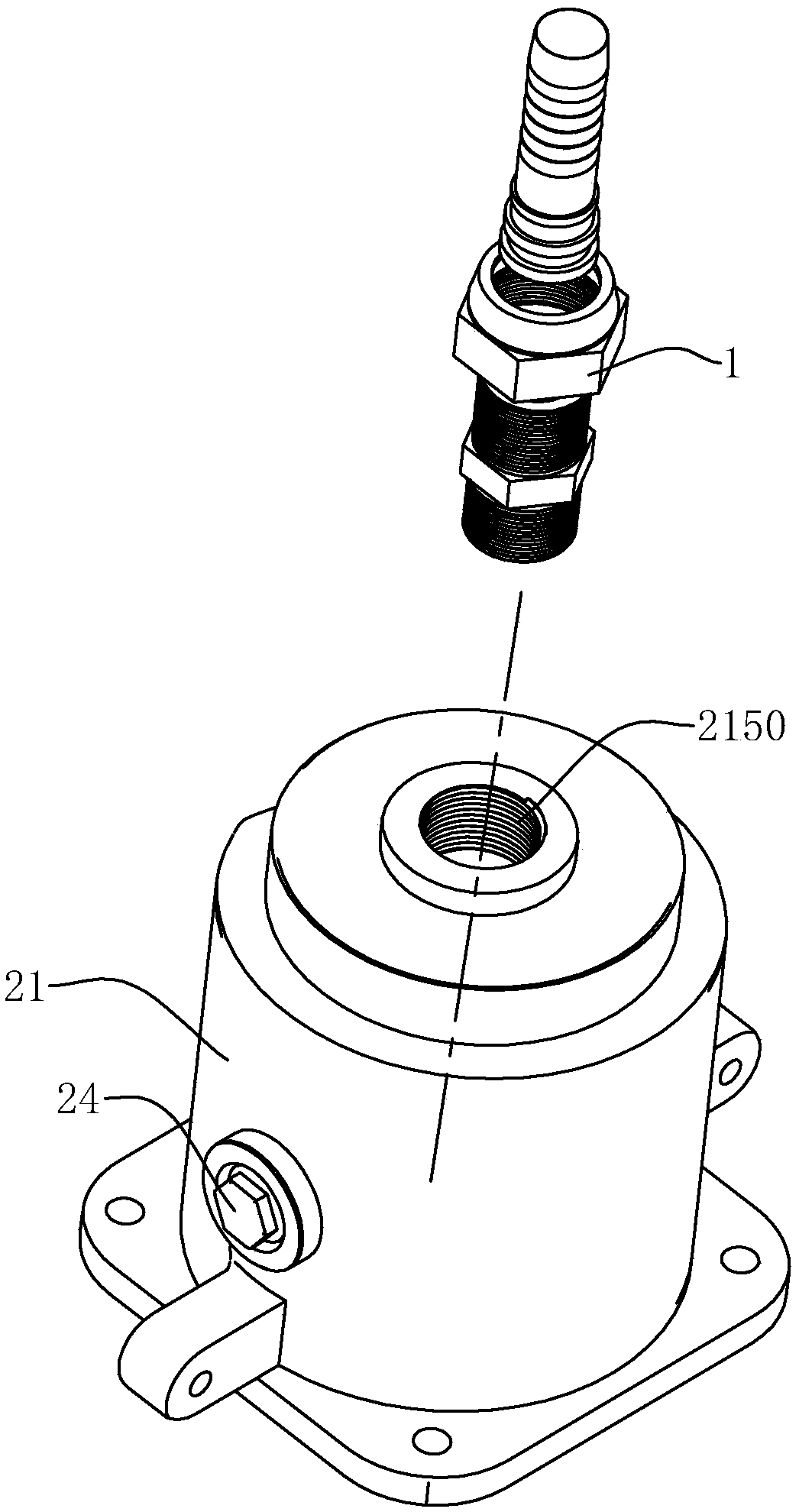

[0039] For lubricator 2, you can continue to refer to image 3 , Figure 4 as well as Figure 5 As shown, the lubricator 2 includes a first cylinder 21 with a first inner cavity 211 and an oil storage chamber 212, a first air valve 22 disposed on the oil storage chamber 212 facing the dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com