winch brake

A winch and torsion spring technology, applied in the direction of the hoisting device, etc., can solve the problems of easy damage and failure, short service life, etc., and achieve the effects of simple structure and assembly, reducing accidents and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Now in conjunction with accompanying drawing, the present invention will be further described.

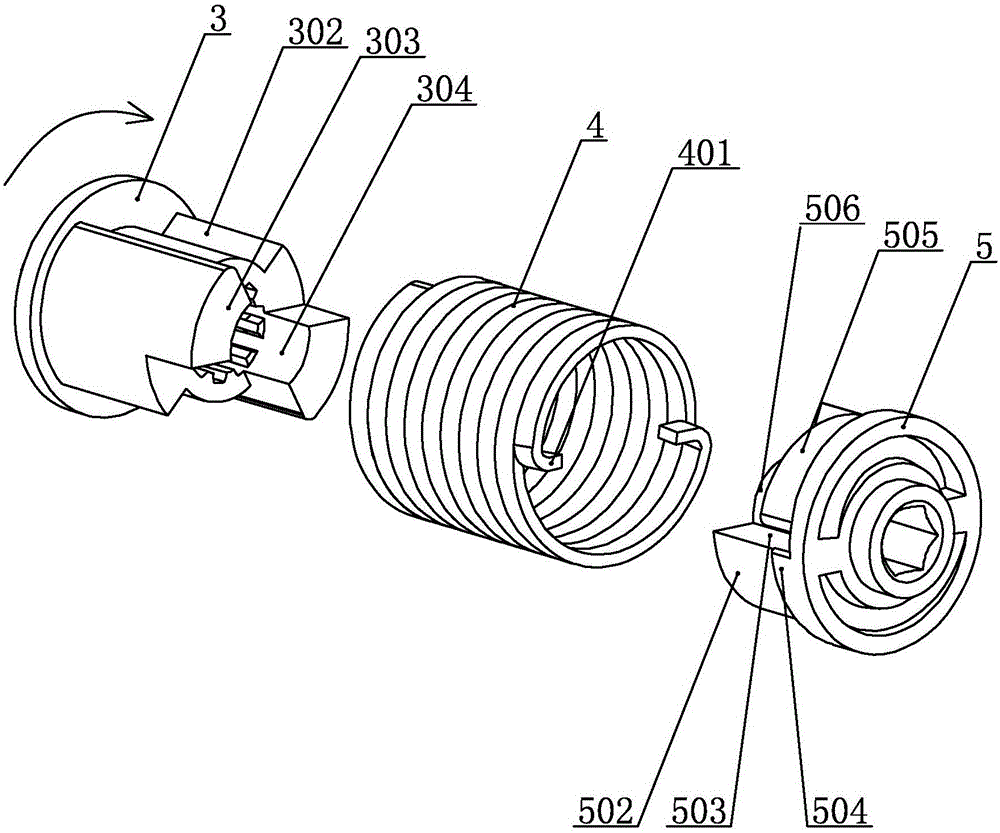

[0017] like figure 1 , figure 2 As shown, the winch brake includes a driving seat 3, an anti-expansion torsion spring 4, a passive seat 5, a positioning bush 6, and a brake sleeve 7. The driving seat is connected to the output end of the motor 1, and the motor is connected to the motor bracket 2. The motor bracket is provided with The sleeve seat 201 where the brake sleeve is socketed, the active seat, the reverse expansion torsion spring, the passive seat, and the positioning bush are connected in sequence, and are limited in the brake sleeve by the circlip 8, wherein the reverse expansion torsion spring is in contact with the brake sleeve in the initial state The frictional contact between the inner walls is smaller than the frictional force between the reverse expansion torsion spring and the brake sleeve during braking. The specific structure and connection are as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com