Rotary high-temperature air preheater

An air preheater, rotary technology, applied in the direction of regenerative heat exchanger, heat exchanger type, indirect heat exchanger, etc., can solve the problem of working temperature, furnace temperature, pressure pulsation, Combustion control device is complex and other problems, to achieve the effect of mature and reliable working principle, numerous manufacturers, and convenient structure assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

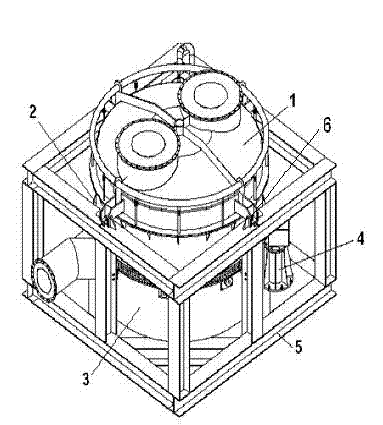

[0035] like figure 1 As shown, it is a schematic structural diagram of a rotary high-temperature air preheater. The rotary high-temperature air preheater is composed of an upper cover 1, a rotor 2, a supporting cylinder 3, a transmission device 4, an external frame 5 and an expansion guide device 6 . The outer frame 5 is provided with a support cylinder 3, a rotor 2 on the support cylinder 3, and a transmission device 4 located on one side of the support cylinder 3. The transmission device 4 is connected to the rotor 2, and the rotor 2 is provided with an upper cover 1. The cover 1 is connected to the outer frame 5 by expansion guides 6 .

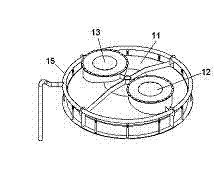

[0036] like figure 2 Shown is a top view of the upper cover, image 3 In its bottom view, the upper cover 1 includes an upper cover shell 11 and an inner heat insulating layer 17 of the upper cover provided on its inner side, and an air seal air supply pipeline 15 is provided at the edge of the upper surface of the upper cover shell 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com