Control method and system for preventing out-of-control of oil drilling engineering drilling rig/traveling block

A technology for engineering drilling rigs and oil drilling, which is applied to the automatic control system of drilling, drilling equipment, earthwork drilling and production, etc. It can solve the problems of personnel injury, machine crash, human death, mistakes, etc., and achieve low cost, good social benefits, and increased The effect of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

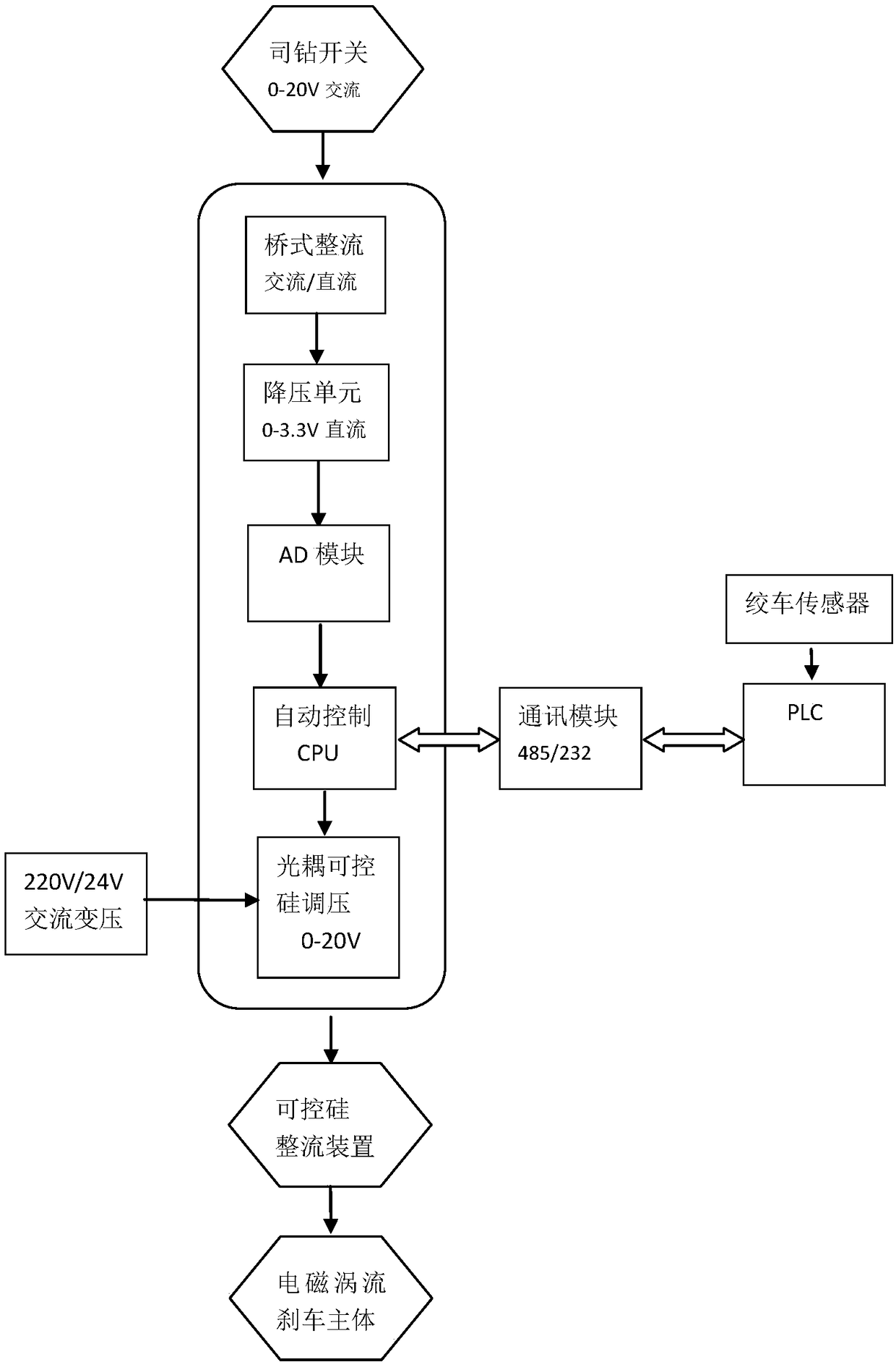

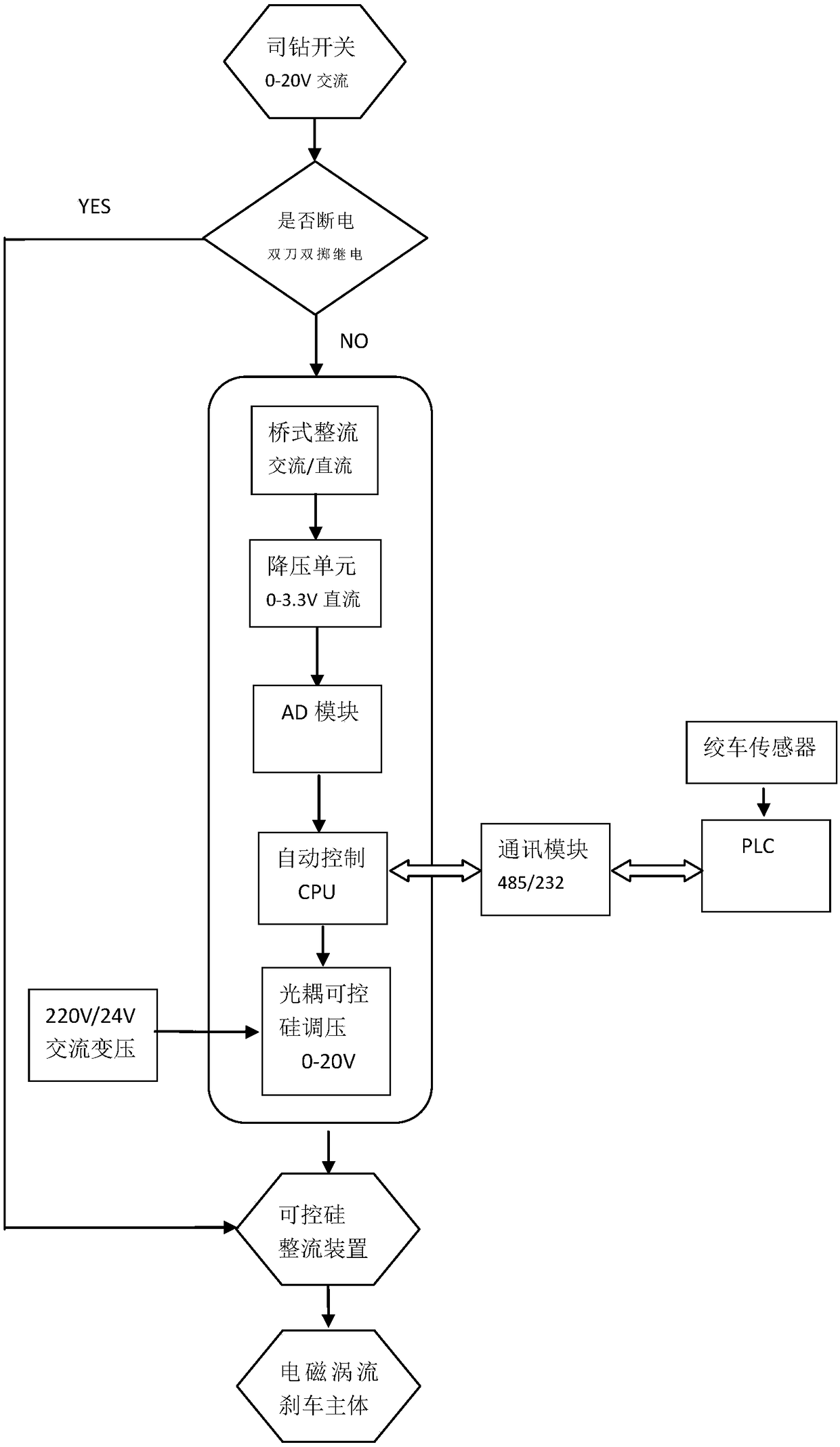

[0028] see figure 1 , the oil drilling engineering drilling rig / traveling block anti-out-of-control control method of the present invention, in the existing drilling rig / traveling block control circuit, an adjustable automatic control template (by signal acquisition) is inserted between the driller's switch and the silicon controlled rectifier device unit, processing unit and thyristor voltage regulating unit) to realize the safety control of drilling rig / cruise intervention:

[0029] 1) The signal acquisition unit collects the low-voltage AC signal output by the driller's switch in real time, and transmits it to the processing unit after rectification and step-down processing. The processing unit detects and analyzes the voltage signal after rectification and step-down processing in real time, and controls the controllable signal according to the instructions of the PLC. The silicon voltage regulating unit modulates and outputs a 0-20V AC voltage signal to the thyristor recti...

Embodiment 2

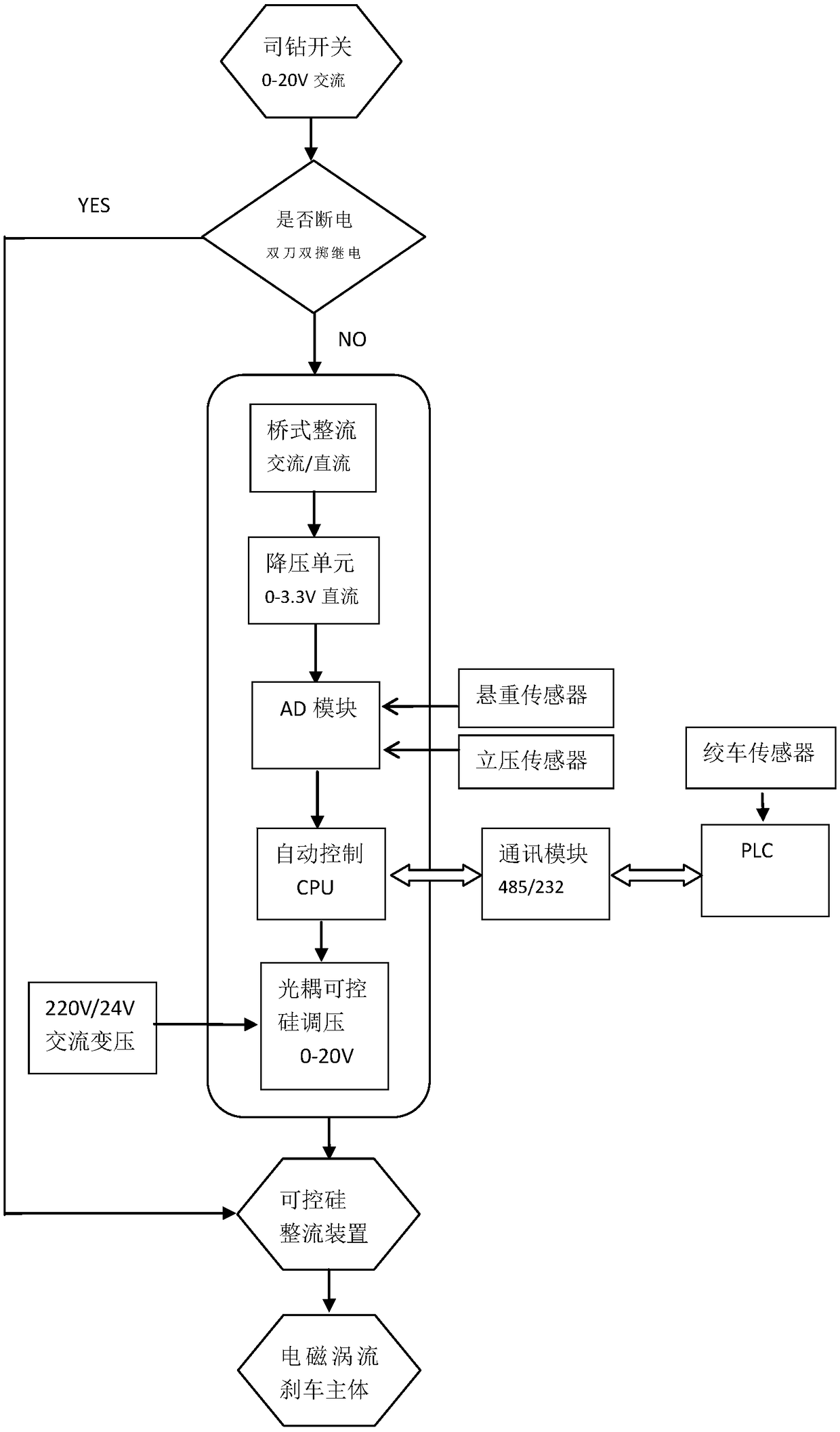

[0032] In oil drilling engineering, when drilling, the driller must operate the driller's switch to activate the electromagnetic eddy current brake to slow down the traveling car at different positions, so as to prevent the traveling car from overspeeding or out of control; the oil drilling rig / cruising car in this embodiment The anti-runaway control method is different from Embodiment 1 in that further, according to this characteristic, the travel distance of the traveling train is divided into N intervals from top to bottom, N is a natural number greater than or equal to 1, and each interval is set There are traveling car height value H, speed value S and matching voltage signal value V;

[0033] PLC real-time detection and analysis of the traveling vehicle height value h, speed value s and voltage signal value v, and real-time comparison with the traveling vehicle height value H, speed value S and voltage signal value V of each interval set;

[0034] 1) If the traveling block...

Embodiment 3

[0038] see Figure 4 , the oil drilling engineering rig / traveling vehicle anti-out-of-control control method of the present embodiment is different from Embodiment 2 in that: when the traveling vehicle is in an out-of-control state, the PLC starts the electromagnetic eddy current brake to slow down the traveling vehicle, and also activates the disc brake interlocking device Send an instruction to make the two-position five-way solenoid valve in the device work immediately, cut off the normally open air circuit A connecting the main clutch and high and low speeds, and open the normally closed air circuit B to supply air to the pneumatic disc brake to achieve the purpose of braking .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com