Permeable base layer and construction method thereof

A technology of permeable base and permeable layer, which is applied in the direction of roads, side ditch/curb, coagulation pavement laid on site, etc. The effect of increasing the rate, increasing the need for immediate drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

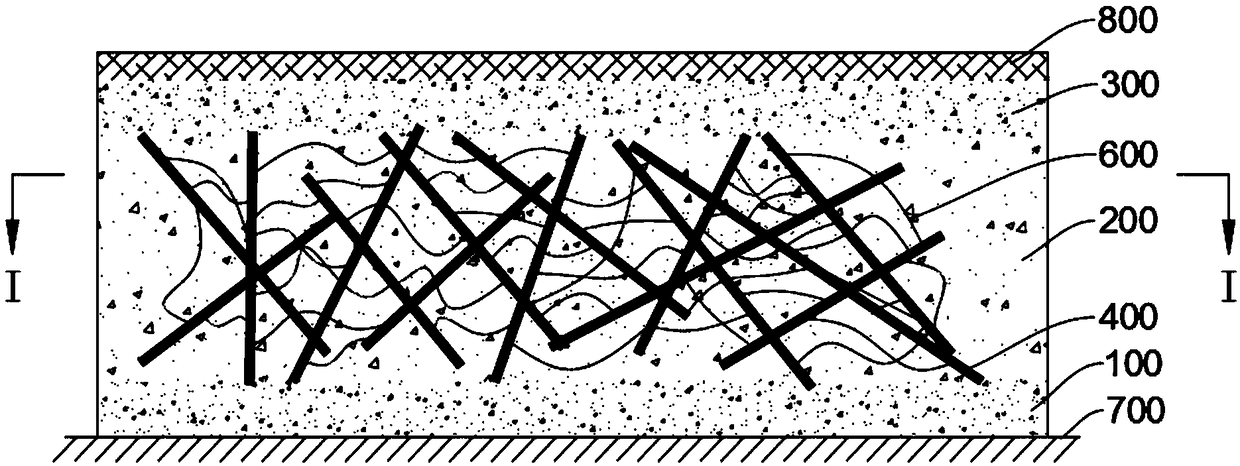

[0031] This embodiment provides a permeable base layer, which is arranged between the roadbed 700 of the permeable pavement 800 and the road surface 800, and is used to solve the problem of high porosity of the base layer and low structural strength when the water permeability is good. Water permeability and higher structural strength, when the water permeability is good, it can also have a better load-bearing capacity, and it is not prone to adverse conditions such as settlement and depression.

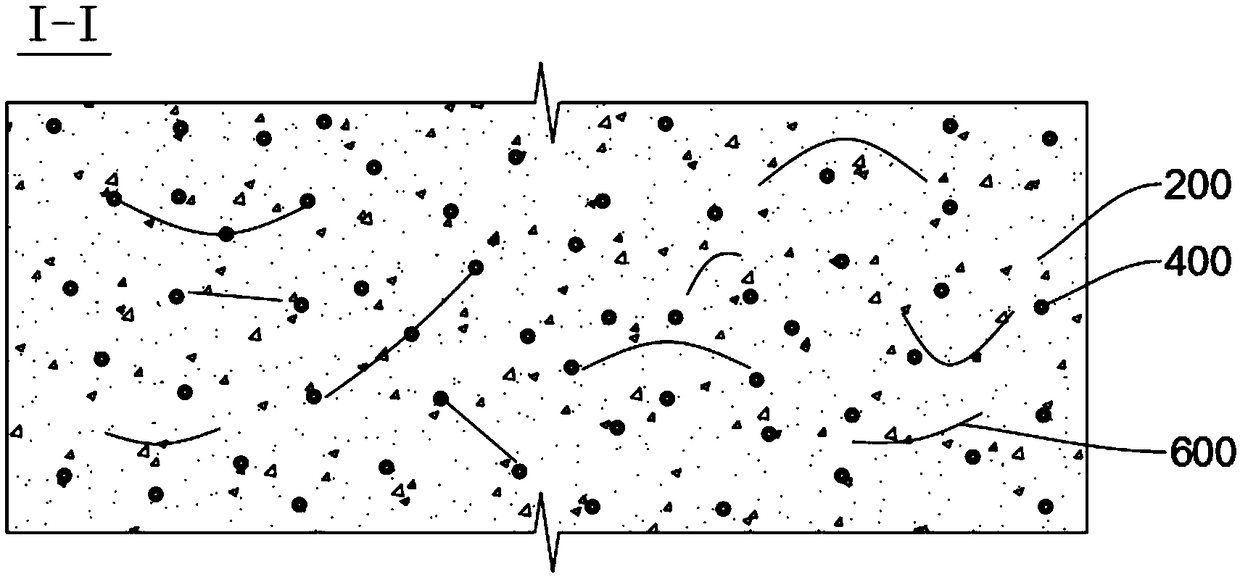

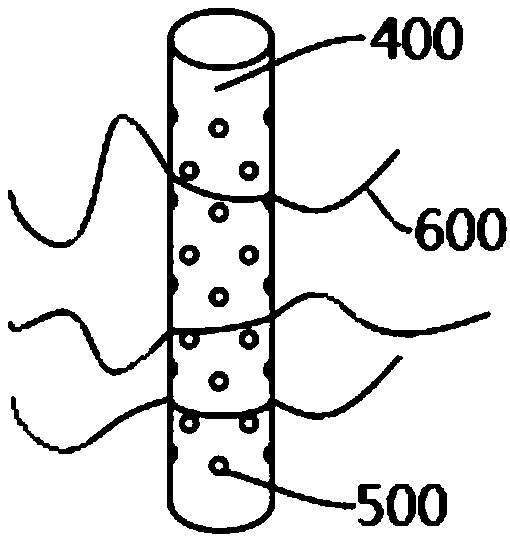

[0032] Attached figure 1 It is a schematic diagram of the cross-sectional structure of the permeable base of the road provided in this embodiment; figure 2 Yes figure 1 Section I-I taken from the stabilization layer 200 in the middle; attached image 3 It is a schematic diagram of the structure of the pipe body 400 provided in the stabilizing layer 200.

[0033] Please refer to the attached figure 1 As shown, the direction from the roadbed 700 to the road surface 800 of the above-mentione...

Embodiment 2

[0061] This embodiment provides a construction method for a permeable base layer, which includes the following steps.

[0062] Laying the first permeable layer 100: laying a gravel concrete layer on the roadbed 700, optionally making the first permeable layer 100 and the roadbed 700 approximately the same width, or optionally making the first permeable layer 100 slightly narrower than the first permeable layer 100, And level it.

[0063] In this embodiment, the width of the first water-permeable layer 100 is 4 m.

[0064] Set the stability layer 200:

[0065] Fixed tube 400

[0066] Before the first water-permeable layer 100 is solidified and formed, a plurality of pipe bodies 400 are obliquely inserted into the first water-permeable layer 100 at a predetermined angle greater than 0° and less than 180° to fix them, and fix the crossing parts of the pipe bodies 400, for example It is fixed by AB glue bonding, or welding, or tying, and the specific fixing method shall be subject to firm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com