Novel fin evaporator leak detection line

A finned evaporator and leak detection technology, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the secondary pollution of products, low drainage efficiency, and inconvenient water replacement and other problems, to achieve the effect of good water saving effect, high leak detection efficiency, economical and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

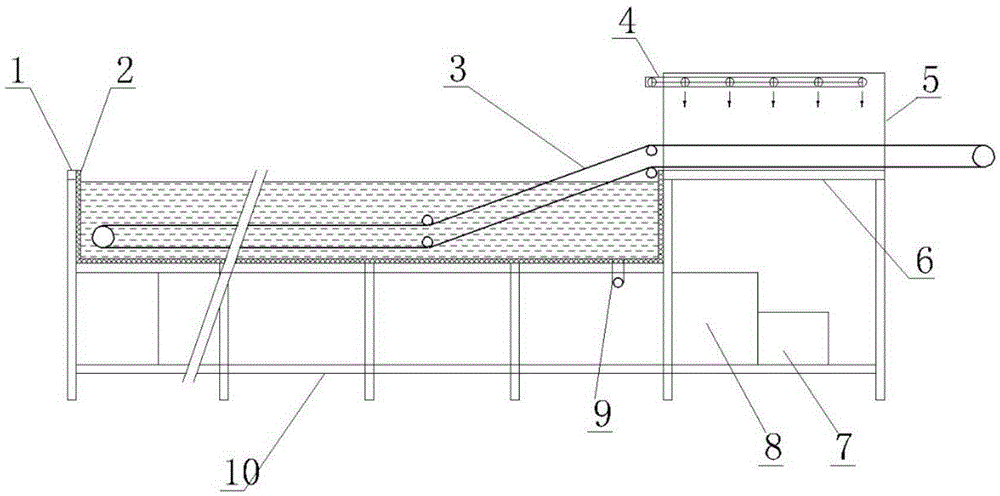

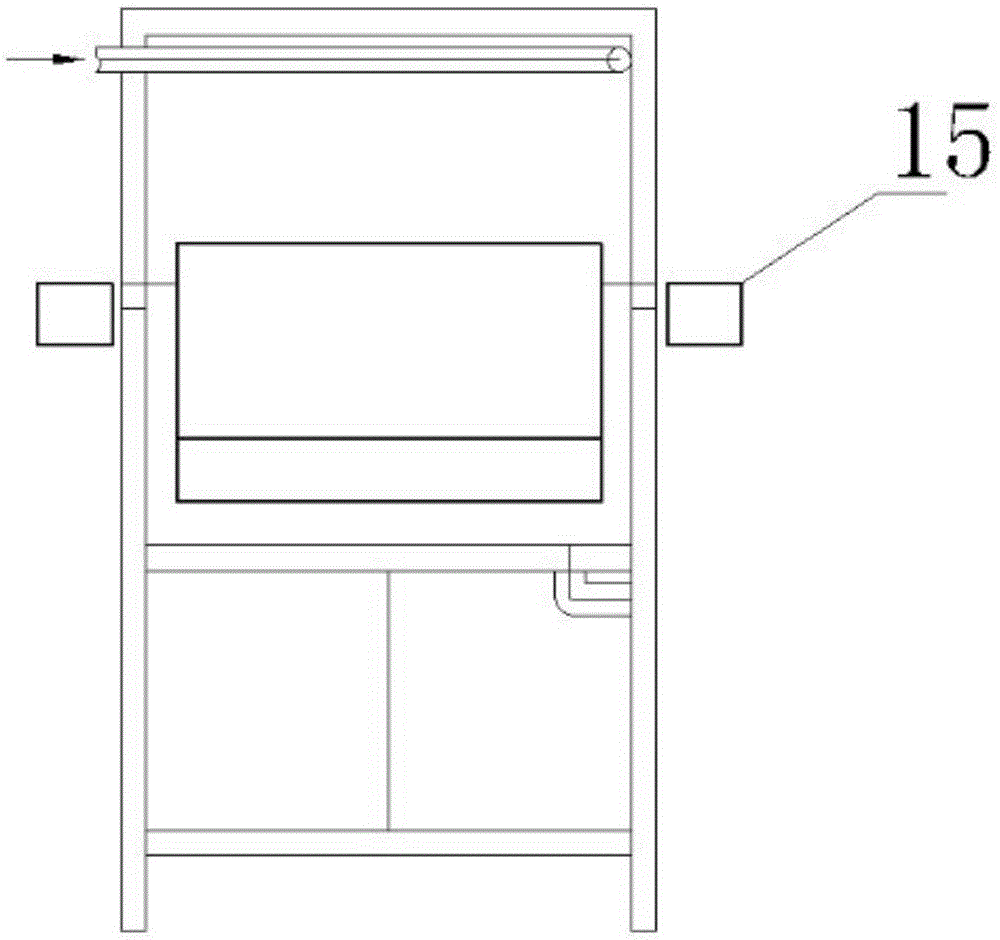

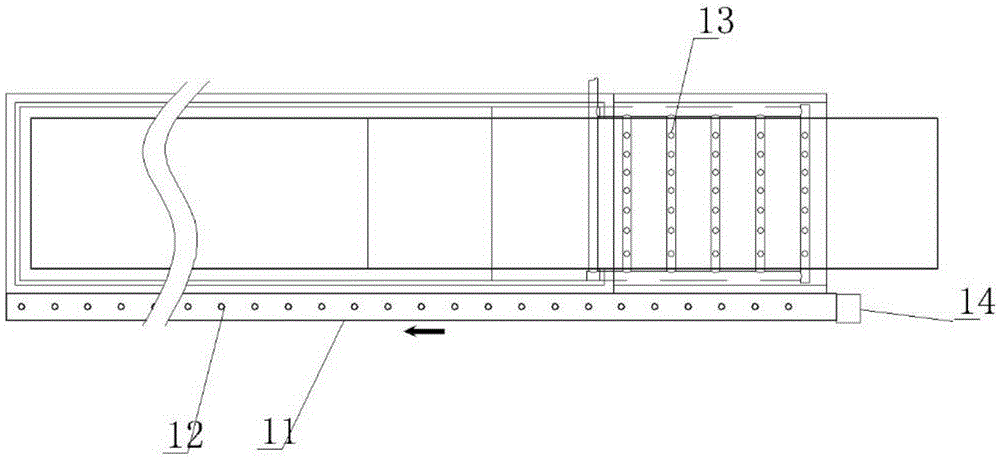

[0016] See accompanying drawing: a kind of novel finned evaporator leak detection line, comprises water tank 1, blower platform 5, conveyer belt 3, quick connector conveying chain 11, stand 10, it is characterized in that described water tank 1 adopts transparent glass to make, and water tank 1 has a drain valve 9 at the bottom, and the bottom of the tank 1 is inclined toward the drain valve 9 with a certain slope. Double-pipe explosion-proof lighting lamps 15 are installed on both sides of the tank 1, and the entire tank 1 is fixed on the stand 10. The device (4, 7, 8) and the water receiving device 6, the moisture collected by the water receiving device 6 can be returned to the water tank 1, the conveyor belt 3 is connected to the water tank 1 and the blowing platform 5, and the transition section from the water tank 1 to the blowing platform 5 is ∠20°±0.2° rises, the quick joint conveyor chain 11 and the conveyor belt 3 share a frequency conversion motor drive, the platform ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com