Wear-resistant super-hydrophobic paper and preparation method thereof

A super-hydrophobic and super-hydrophobic modification technology, applied in the fields of special functional paper and nanotechnology, can solve the problems of poor super-hydrophobic stability, complicated preparation process, no additional properties, etc., achieve good hydrophobic properties, simple preparation method, and improve additional performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A wear-resistant super-hydrophobic paper, prepared according to the following steps:

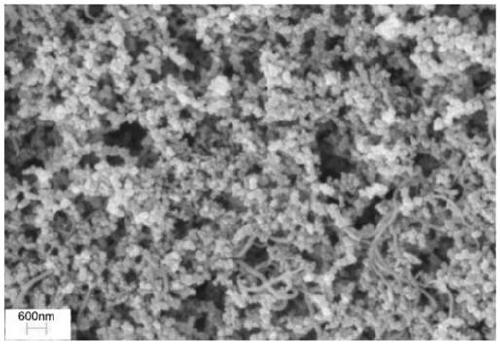

[0037] (1) First mix 5mL of ammonia water and 65mL of ethanol solution into the Erlenmeyer flask; another 5mL of tetraethyl silicate is dissolved in 25mL of ethanol, so that tetraethyl silicate is fully dispersed in the ethanol solution, and the obtained silicic acid Add the tetraethyl ester solution into the Erlenmeyer flask mentioned above, and continuously magnetically stir it to make it fully react for 12 hours, and the magnetic stirring speed is 300r / min; The supernatant was removed after centrifugation at 8000r / min, and the resulting lower sediment was vacuum-dried for 5 hours to obtain nano-silica particles. figure 1 .

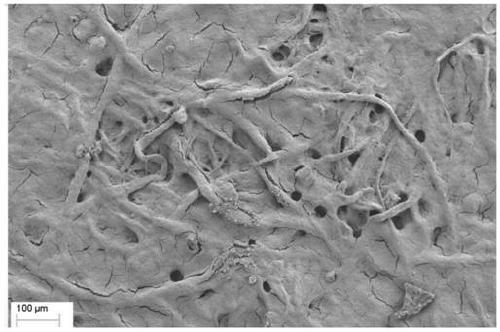

[0038] (2) Take by weighing 5 g of nano-silica prepared in step (1) and mix hydroxylated carbon nanotubes with a quality of 6 mg in 50 mL of toluene, ultrasonically disperse for 30 min, then add vinyltriethoxysilane, and carry out Superhydrophobic modificatio...

Embodiment 2

[0044] A wear-resistant super-hydrophobic paper, prepared according to the following steps:

[0045] (1) First mix 5mL of ammonia water and 65mL of ethanol solution into the Erlenmeyer flask; another 5mL of tetraethyl silicate is dissolved in 25mL of ethanol to fully disperse it in the ethanol solution, and the resulting tetraethyl silicate solution Add it into the Erlenmeyer flask mentioned above, and continuously magnetically stir to make it fully react for 12h, the magnetic stirring speed is 300r / min; after the reaction is completed, the obtained suspension is centrifuged, the centrifugation time is 3h, and the centrifugal speed is 8000r / min , after centrifugation, the supernatant was removed, and the obtained lower sediment was vacuum-dried for 5 hours to obtain nano-silica particles.

[0046] (2) Take by weighing 5 g of nano-silica prepared in step (1) and mix hydroxylated carbon nanotubes with a quality of 10 mg in 50 mL of toluene, ultrasonically disperse for 30 min, th...

Embodiment 3

[0052] A wear-resistant super-hydrophobic paper, prepared according to the following steps:

[0053] (1) First mix 5mL of ammonia water and 65mL of ethanol solution into the Erlenmeyer flask; another 5mL of tetraethyl silicate is dissolved in 25mL of ethanol to fully disperse it in the ethanol solution, and the resulting tetraethyl silicate solution Add it into the Erlenmeyer flask mentioned above, and continuously magnetically stir it to make it fully react for 12 hours, and the magnetic stirring speed is 300r / min; , after centrifugation, the supernatant was removed, and the obtained lower sediment was vacuum-dried for 5 hours to obtain nano-silica particles.

[0054] (2) Take by weighing 5 g of nano silicon dioxide prepared in step (1) and mix it with hydroxylated carbon nanotubes of 20 mg in 50 mL of toluene, ultrasonically disperse for 30 min, then add vinyltriethoxysilane, and carry out superhydrophobic modification.

[0055] (3) AKD is dissolved in the heptane solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com