Thermosensitive conducting hydrogel with enhanced metal ion coordination and preparation method thereof

A technology of conductive hydrogel and metal ions is applied in the field of temperature-sensitive conductive hydrogel and its preparation, which can solve the problems of cumbersome preparation method, single application field, lack of fast and effective response mechanism for high-strength hydrogel, etc. To achieve the effect of simple preparation method, avoiding uneven force, and adjustable mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

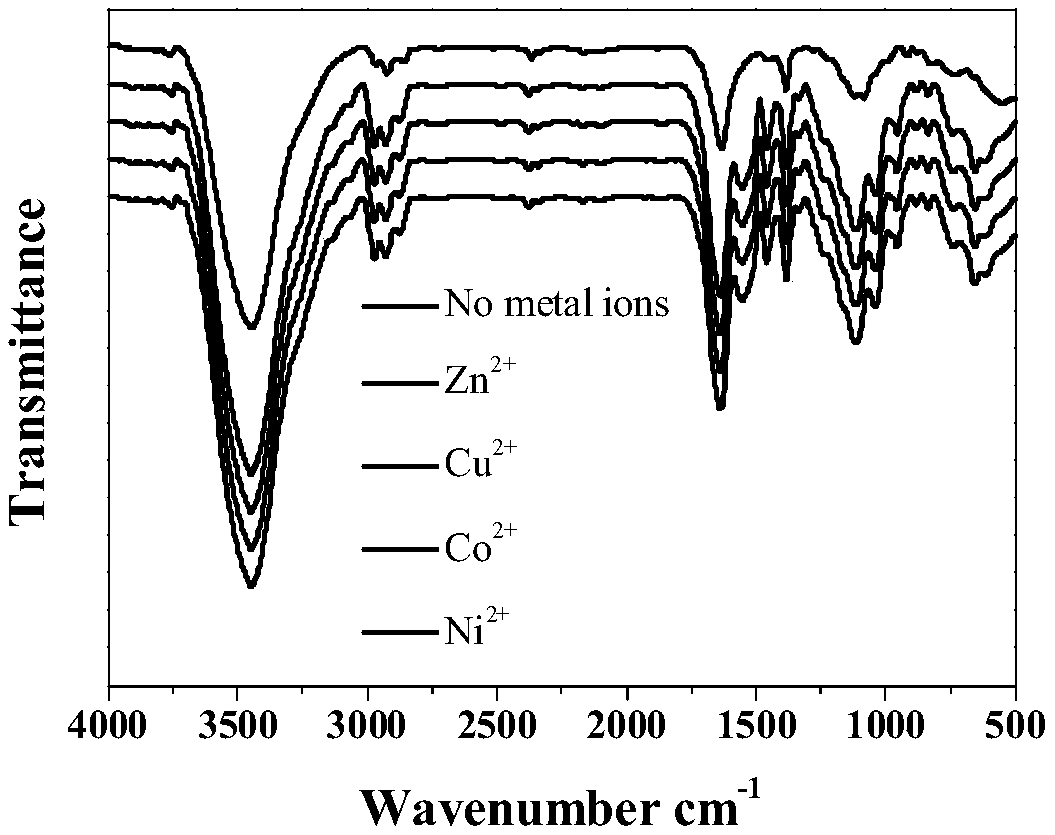

Image

Examples

Embodiment 1

[0051] 1. Purification of N-isopropylacrylamide: Weigh 5g of N-isopropylacrylamide, add it to 8ml of toluene, heat to 50°C to dissolve, add 25ml of n-hexane, and put the filtrate at -20°C after suction filtration Two hours later, white crystals were obtained by suction filtration, and this was repeated three times. The obtained product was vacuum-dried at 30°C, sealed and placed in a refrigerator at 5°C for later use.

[0052] 2. A method for preparing a temperature-sensitive conductive hydrogel coordinated by metal ions, comprising the steps of:

[0053] (1) The N-isopropylacrylamide purified in this example and the monomer vinylimidazole were dissolved in deionized water at a mass ratio of 2:5, with a solid content of 30% and a chemical crosslinking degree of 0.3%. , then add the crosslinking agent N,N'-methylenebisacrylamide according to 0.3% of the total monomer mole fraction, add the initiator ammonium persulfate and accelerator N,N according to 1.0% of the total monomer ...

Embodiment 2

[0059] A method for preparing a temperature-sensitive conductive hydrogel coordinated by a metal ion, comprising the steps of:

[0060] (1) Dissolve N-isopropylacrylamide and monomer vinylimidazole purified in this example in deionized water at a mass ratio of 1:1, with a solid content of 40% and a chemical crosslinking degree of 0.4%, and then Add cross-linking agent N,N'-methylenebisacrylamide at 0.2% of the total molar fraction of monomers, add initiator ammonium persulfate and accelerator N,N,N' at 1.0% of total monomer molar fraction , N'-tetramethylethylenediamine, dissolved and mixed evenly, reacted at 30°C for 20 hours for pre-polymerization, and after the reaction was complete, a chemically cross-linked hydrogel precursor was obtained;

[0061] (2) Take out the hydrogel precursor prepared in step (1), soak it in an aqueous solution with a concentration of 10mM cobalt chloride for 6h for coordination (temperature 30°C), and then soak it in water at 30°C for 6h to remov...

Embodiment 3

[0063] A method for preparing a temperature-sensitive conductive hydrogel coordinated by a metal ion, comprising the steps of:

[0064] (1) Dissolve N-isopropylacrylamide and monomer vinylimidazole purified in this example in deionized water at a mass ratio of 3:2, with a solid content of 20% and a chemical crosslinking degree of 0.2%, and then Add crosslinking agent N,N'-methylenebisacrylamide at 2.0% of the total molar fraction of monomers, add initiator ammonium persulfate and accelerator N,N,N' at 3.0% of total monomer molar fraction , N'-tetramethylethylenediamine, dissolved and mixed evenly, reacted at 20°C for 28 hours for pre-polymerization, and after the reaction was complete, a chemically cross-linked hydrogel precursor was obtained;

[0065] (2) Take out the hydrogel precursor prepared in step (1), soak in 90mM zinc nitrate aqueous solution for 10h for coordination (temperature 20°C), and then soak in 20°C water for 10h to remove excess uncrosslinked ligand The ion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com