Nondestructive friction-induced nano-processing method

A technology of friction induction and nano-processing, applied in the field of nano-processing, can solve the problems of a large number of inorganic reactants being powerless, achieve the effect of shortening the etching time, simple method, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The damage-free friction-induced nanofabrication method of this embodiment includes the following steps:

[0030] S1, the monocrystalline silicon sample was ultrasonically cleaned with acetone, absolute ethanol and secondary deionized water for 5 minutes;

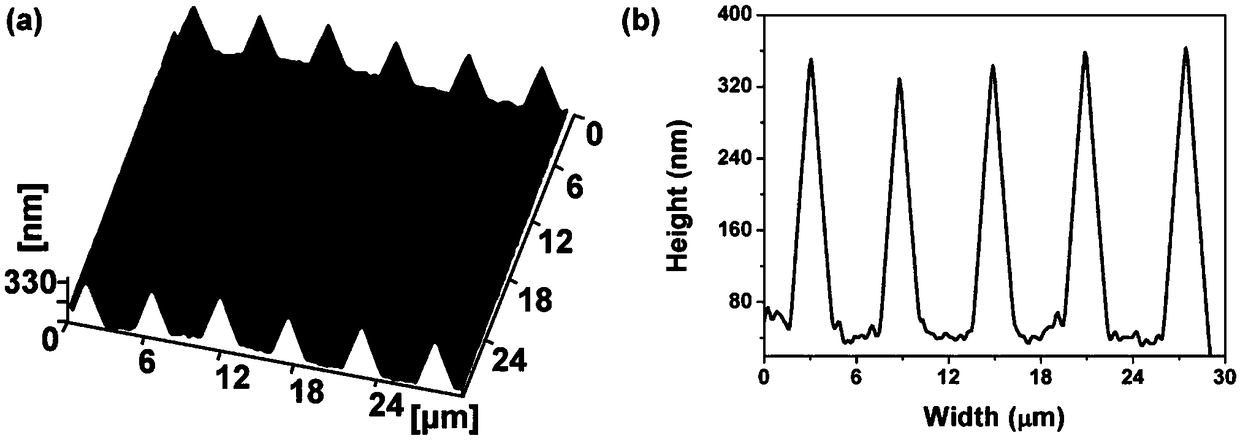

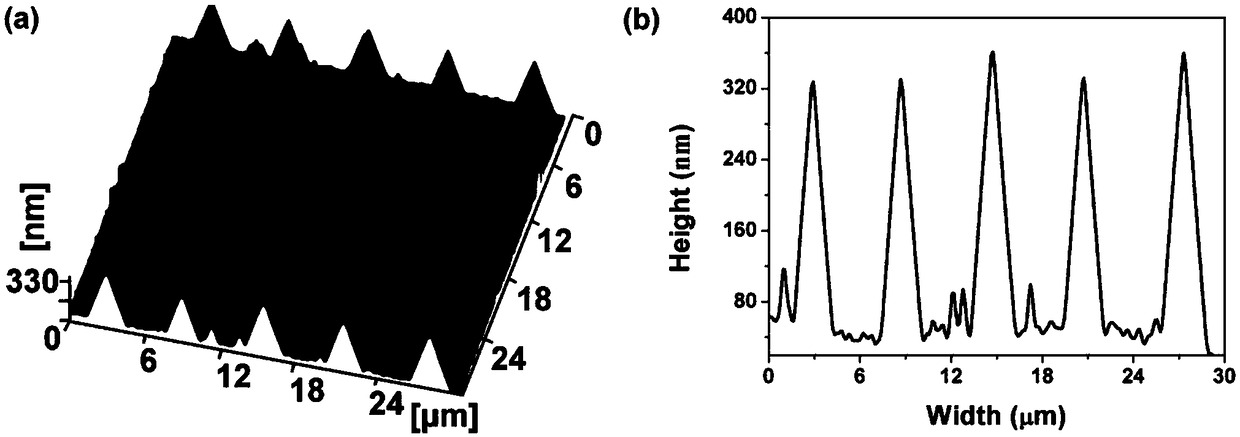

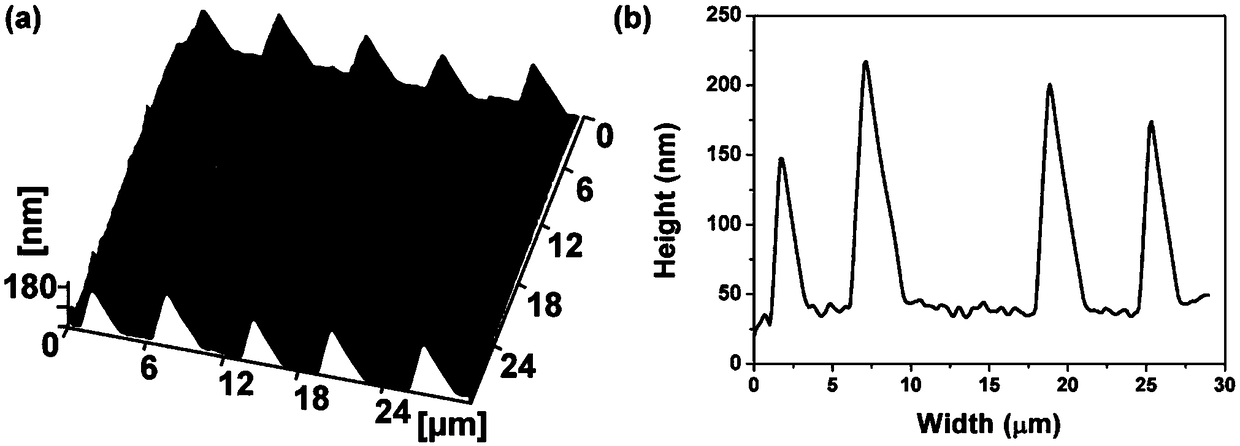

[0031] S2. Place the single crystal silicon sample cleaned in step S1 on a multi-probe nano-processing device, and use the diamond probe to perform scanning processing on the surface of the single crystal silicon sample according to the set processing parameters;

[0032] S3, configure a mixed solution of KOH solution and isopropanol with a mass concentration of 20%, the volume ratio of KOH solution and isopropanol is 5:1, and place the plastic beaker containing the solution in a heat-collecting magnetic stirrer The water bath is heated and kept at a constant temperature of about 25°C, and the rotational speed of the modulated rotor is 350 rpm and kept constant;

[0033] S4. Rinse the monocrystalline silicon sample ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com