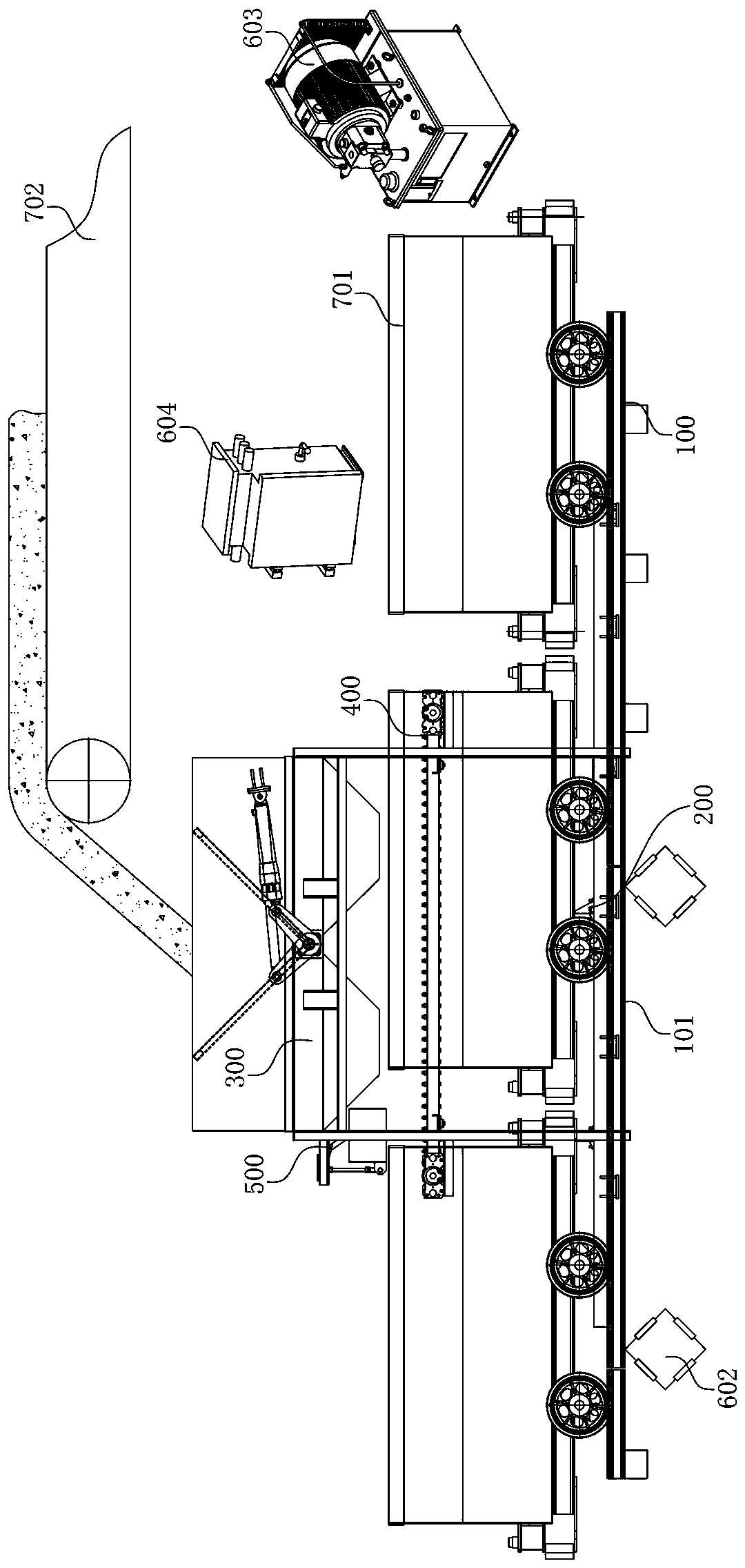

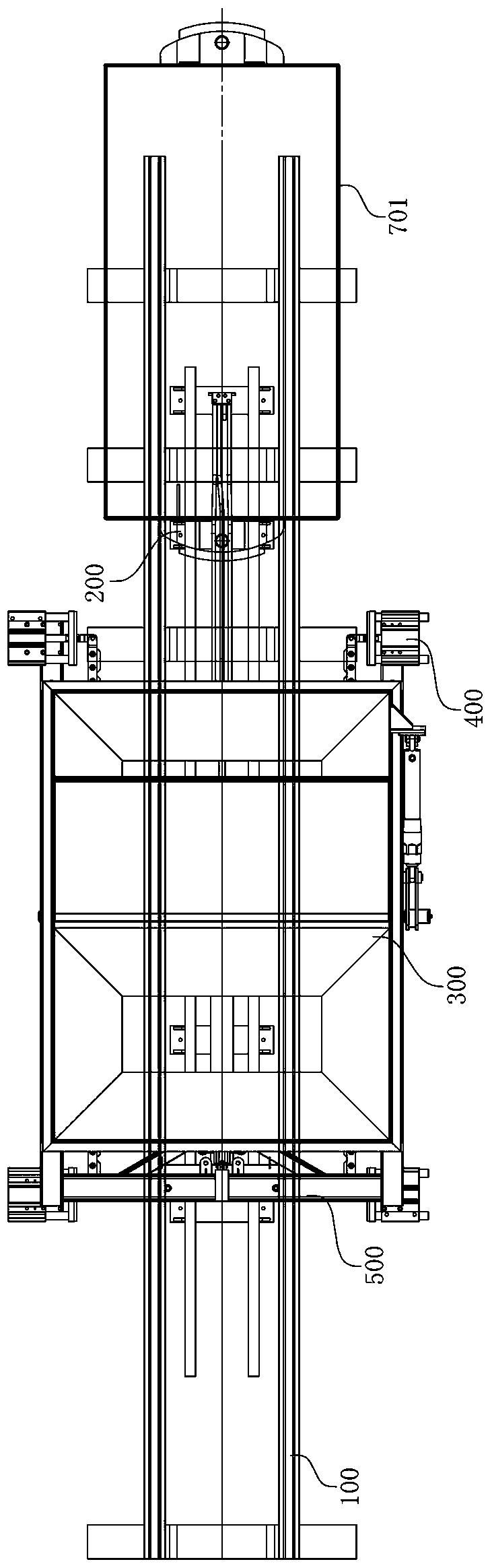

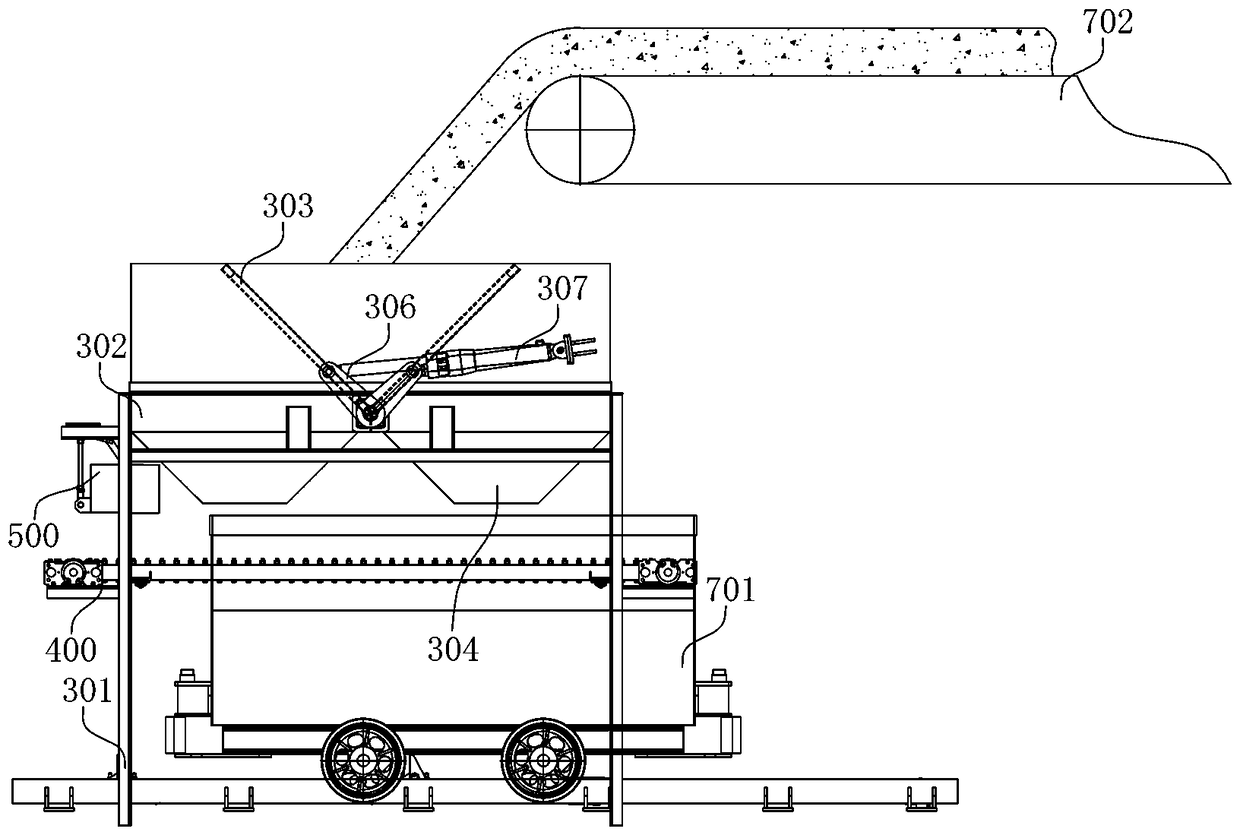

Continuous automatic gangue loading system and method for tramcars

A mine car, automatic technology, applied in the field of mine car continuous automatic loading and unloading system, can solve the problems of unautomated operation and loading and unloading, intermittent stop of conveyor belt, impact on work efficiency, etc., to improve the level of automatic operation, stable operation, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0067] As a kind of specific implementation mode, the charging step of mine car continuous automatic loading gangue method is as follows:

[0068] 1. The mine car enters the working area, the position sensor detects the mine car, and the car blocking component blocks the mine car to locate the mine car.

[0069] 2. Turn over the action, select the first discharge port for discharge.

[0070] 3. The coal gangue conveyor belt is started for gangue loading.

[0071] 4. The mine cart pushing component pushes the mine cart forward so that the mine cart reaches the position of the second feeding port.

[0072] 5. Turn over the action, switch the second discharge port to discharge the material for the mine car to continue loading.

[0073] 6. When one-third of the material in the mine car is loaded, the mine car push component pushes the mine car forward, and the mine car stays in the middle position.

[0074] 7. When two-thirds of the material in the mine car is loaded, the mine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com