Novel low-carbon and environment-friendly plate extruder

A low-carbon, environmentally-friendly, extruder technology, applied in the field of extruders, can solve the problems that the conveyor belt is easily damaged by heat, easy to generate excessive air bubbles, and increase the quality of low-carbon and environmentally-friendly sheets, so as to prevent easy damage by heat, The effect of increasing the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

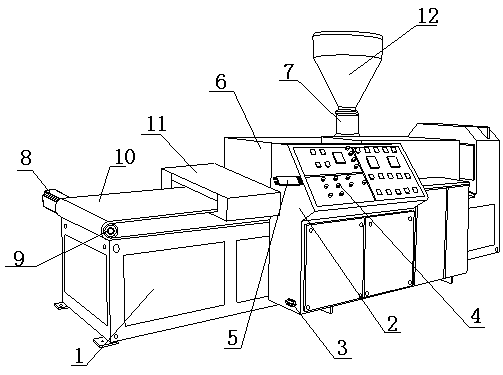

[0028] In this technical solution:

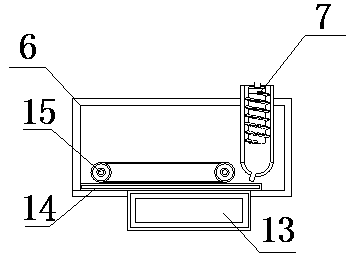

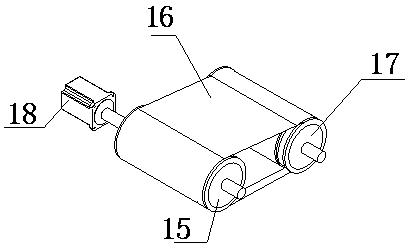

[0029] Extrusion device 7, outer tube 71, semicircle-arc extrusion head 72, third motor 73, conical cover 74, rotating shaft 75, auger 76, cooling device 11, concave shell 111, cooling plate 112, conduit 113, water pump 114, copper sheet 115, and roller 116 contain substantial innovative components for the present invention.

[0030] Case 1, control box 2, power socket 3, control switch 4, single chip microcomputer 5, working box 6, first motor 8, first roller 9, conveyor belt 10, hopper 12, heater 13, processing tank 14, second The second roller 15, the plastic transmission belt 16, the third roller 17 and the second motor 18 are the indispensable connecting components for realizing the technical solution of the present invention.

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying draw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com