Efficient nano catalyst to convert CO2 into cyclocarbonate and preparation method thereof

A nano-catalyst, cyclic carbonate technology, applied in physical/chemical process catalysts, chemical instruments and methods, organic chemistry and other directions, can solve the problems of high catalyst cost, harsh catalytic conditions, poor stability, etc., to achieve high product yield, The preparation method is simple and the effect is not easy to decompose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention provides a CO 2 The preparation method that is converted into the efficient nano-catalyst of cyclic carbonate, comprises the following steps:

[0033] (1) crushing and screening natural attapulgite ore to remove impurities to obtain attapulgite powder;

[0034] (2) Disperse the attapulgite powder into the first solvent, add a modifier, stir and react, then centrifuge, wash, and dry to obtain the high-efficiency nano-catalyst.

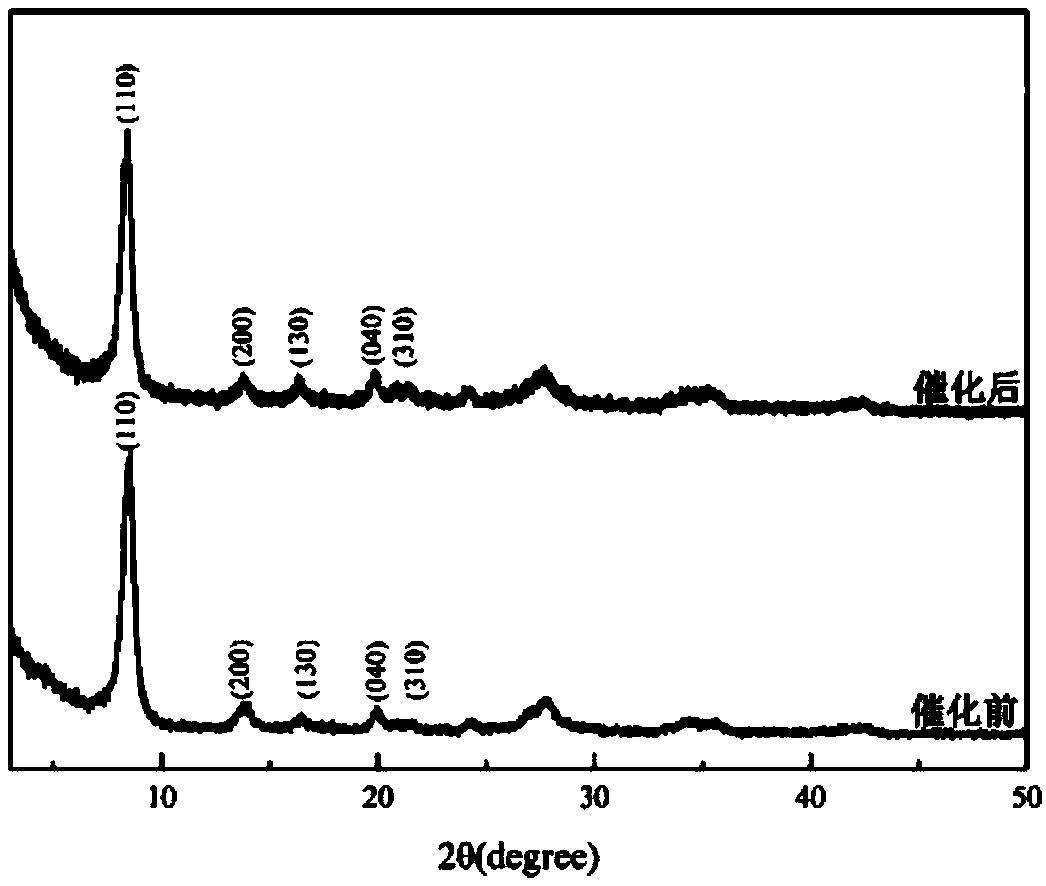

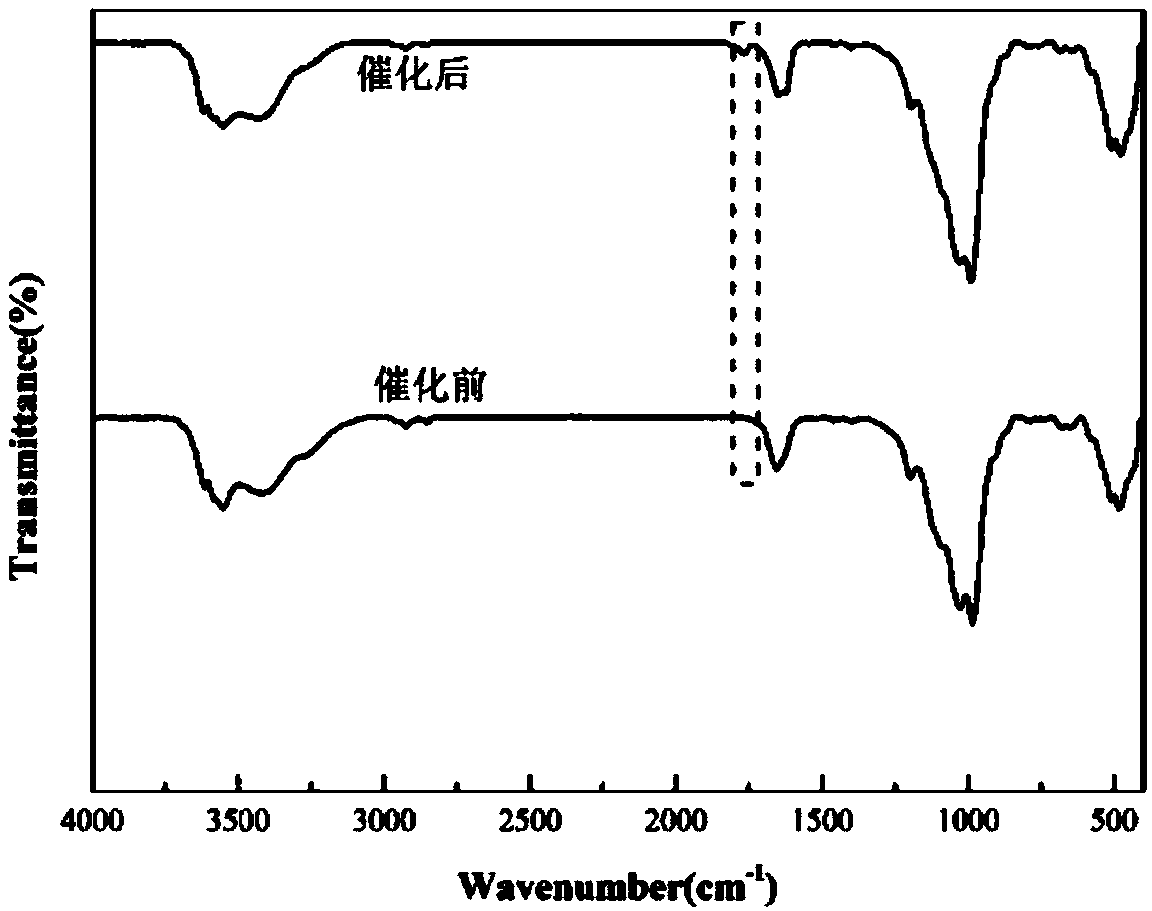

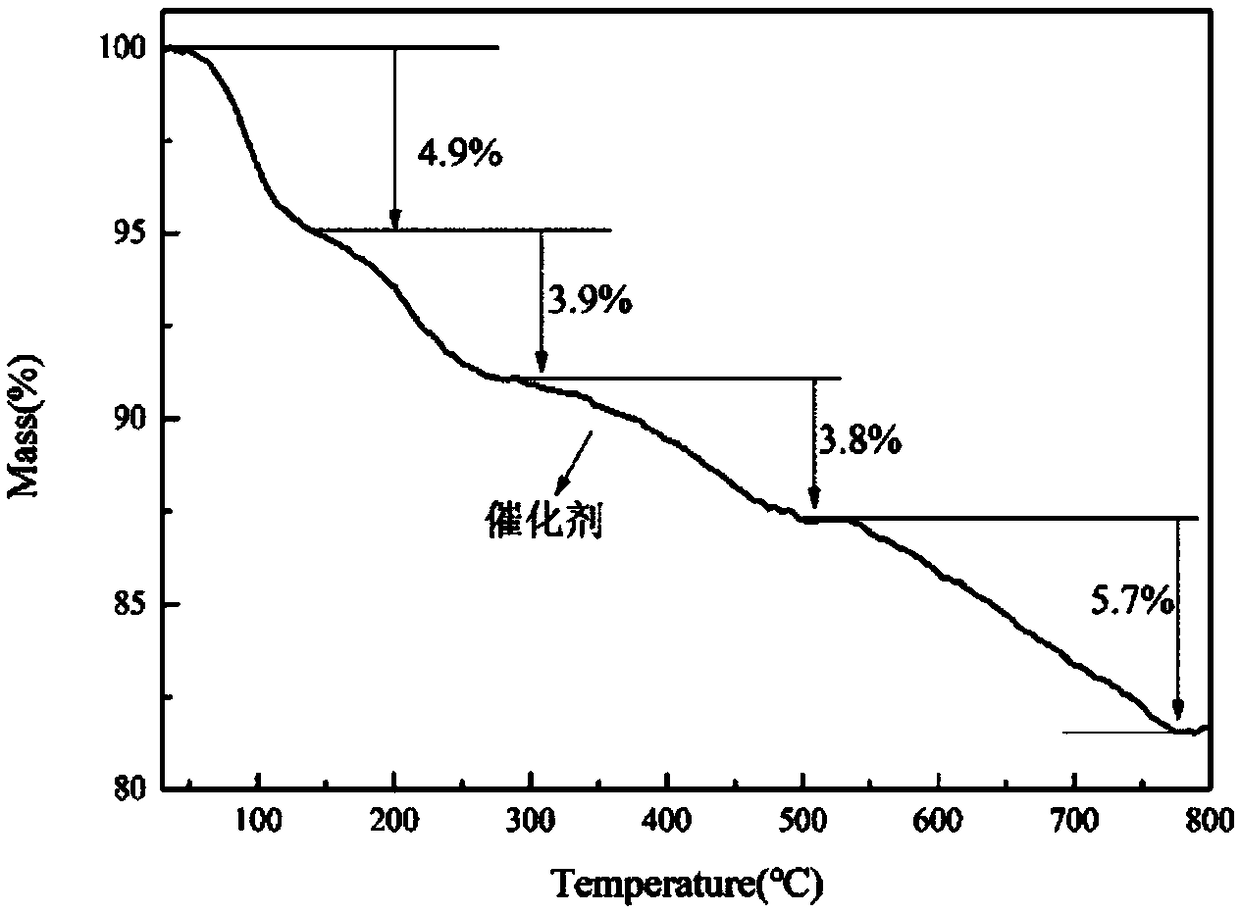

[0035] The attapulgite powder described in the present invention is a natural one-dimensional nanomaterial with good chemical stability and thermal stability, and its structure is a water-containing magnesium-aluminum-silicon powder with a 2:1 type chain layer structure Salt clay minerals, metals in its structure can be replaced to obtain catalysts with different properties. Attapulgite powder has good characteristics such as unique pore structure, high temperature resistance, salt-alkali resistance and large specific surf...

Embodiment 1

[0050] a CO 2 The preparation method that is converted into the efficient nano-catalyst of cyclic carbonate, comprises the following steps:

[0051] S1: The natural attapulgite ore is crushed and screened to remove impurities to obtain attapulgite powder;

[0052] S2: Put 30g of attapulgite powder into a 500ml two-necked bottle equipped with a mechanical stirring device, add 250ml of deionized water as a solvent, and then add 0.6g of NaBF 4 As a modifying agent: control the temperature at 35-55° C., react for 2 hours, and after the reaction is completed, lower the temperature to room temperature, then centrifuge the product, wash it, and dry it to obtain the high-efficiency nano-catalyst.

Embodiment 2

[0054] As the efficient nano-catalyst prepared in Example 1, obtain 0.5g, be dispersed in 50ml ultrapure water, add 0.5mmol Zn(NO 3 ) 2 , 0.1mmol Co(NO 3 ) 2 and 0.1mmol of Ni(NO 3 ) 2 Dissolve it completely, ultrasonically disperse it for 5 minutes, then place it in a constant temperature reactor at 60°C, keep it warm for 30 days, centrifuge, wash and dry the product to obtain the catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com