A nitrogen oxide tail gas treatment system

A technology for exhaust gas treatment and nitrogen oxides, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation. , the effect of high absorption efficiency and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

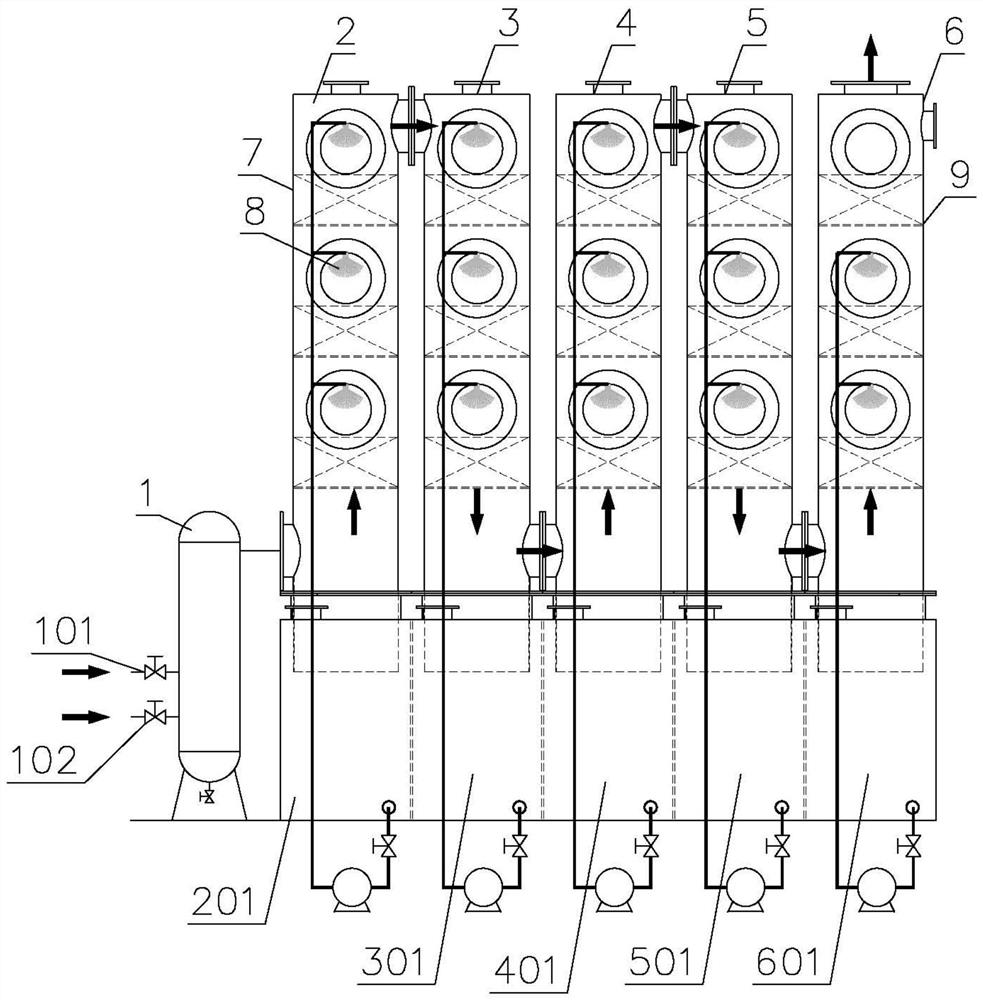

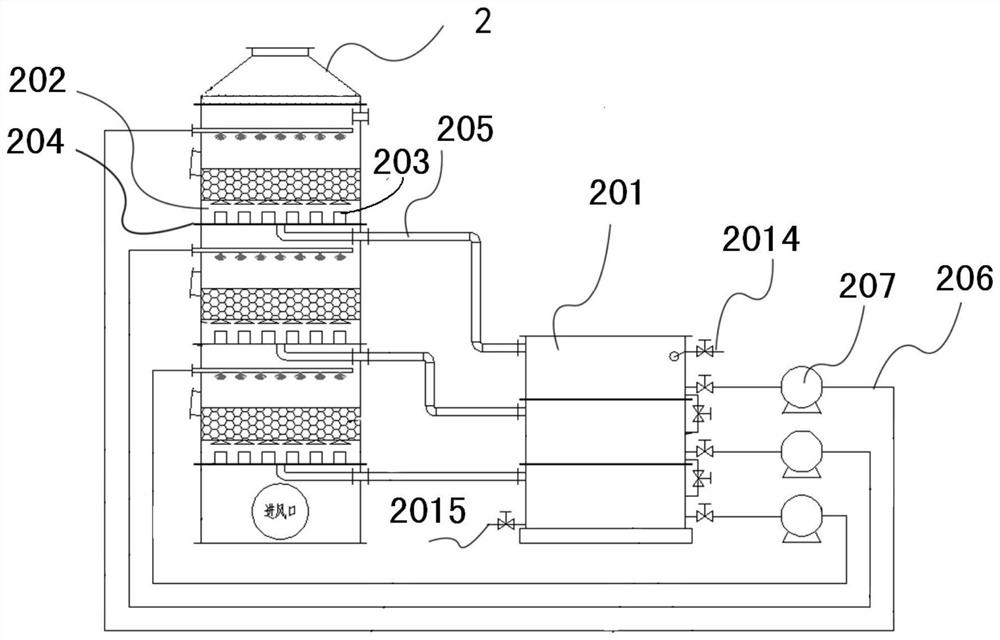

[0056] An embodiment of the tail gas treatment system containing nitrogen oxides in the present invention, the tail gas treatment system containing nitrogen oxides in this embodiment includes a buffer tank 1, a first spray tower 2, a second spray tower 3, a third spray tower Spray tower 4, the 4th spray tower 5 and the 5th spray tower 6, described first spray tower 2, the second spray tower 3, the 3rd spray tower 4, the 4th spray tower 5 and the 5th spray tower Five spray towers 6 all comprise three layers of packing layers 7, and above the packing layers of the first spray tower 2, the second spray tower 3, the third spray tower 4 and the fourth spray tower 5, spraying Spraying device 8; above the bottom two packing layers of the fifth spraying tower 6, there are spraying devices, and the top packing layer is a defogging packing layer 9, which is located at the top air outlet for removing water vapor in the gas.

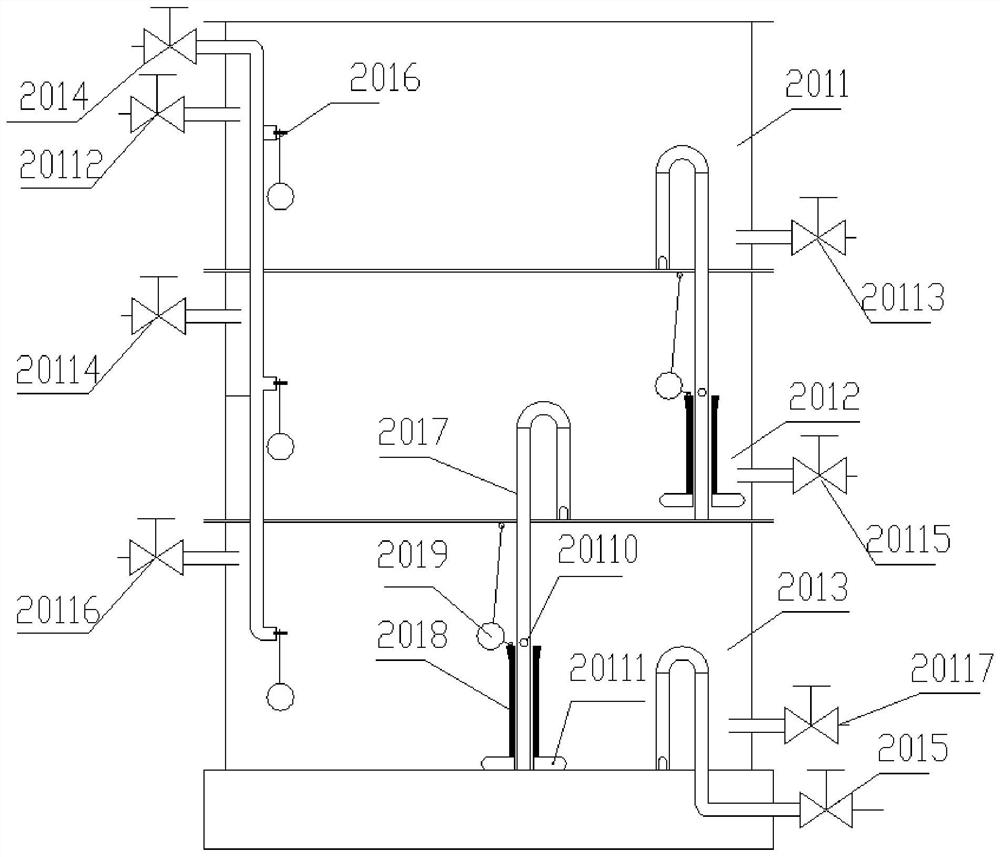

[0057] The bottom of the first spray tower 2 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com