Tail gas washing device and method applicable to cyclone drying process of PVC resin

A PVC resin, drying process technology, applied in the direction of combination device, separation method, chemical instrument and method, etc., can solve the problems of inability to remove impurity gas, reduced tail gas separation effect, large load of packing system, etc., achieves simple structure, convenient industrial The effect of promotion and reduction of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

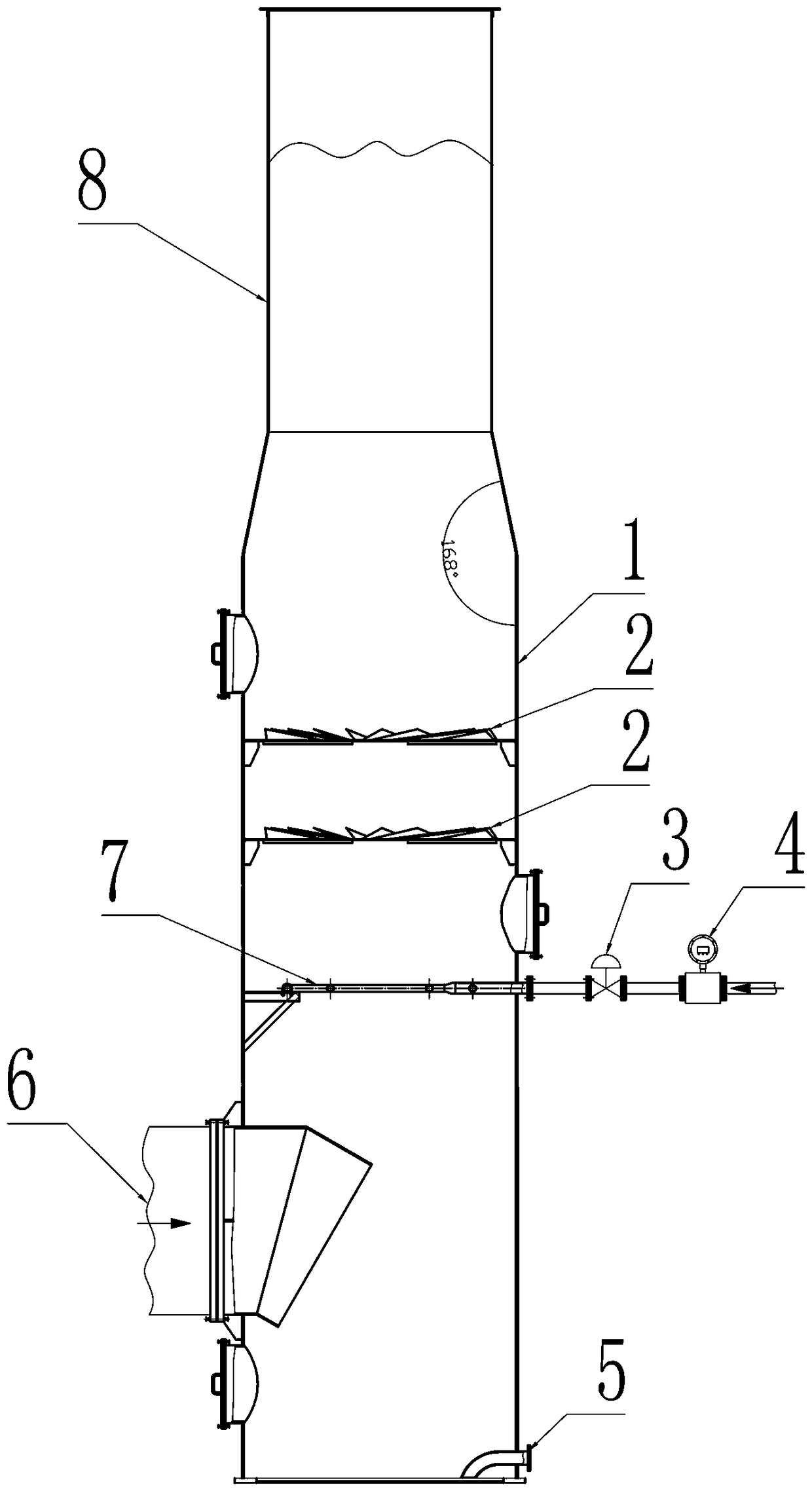

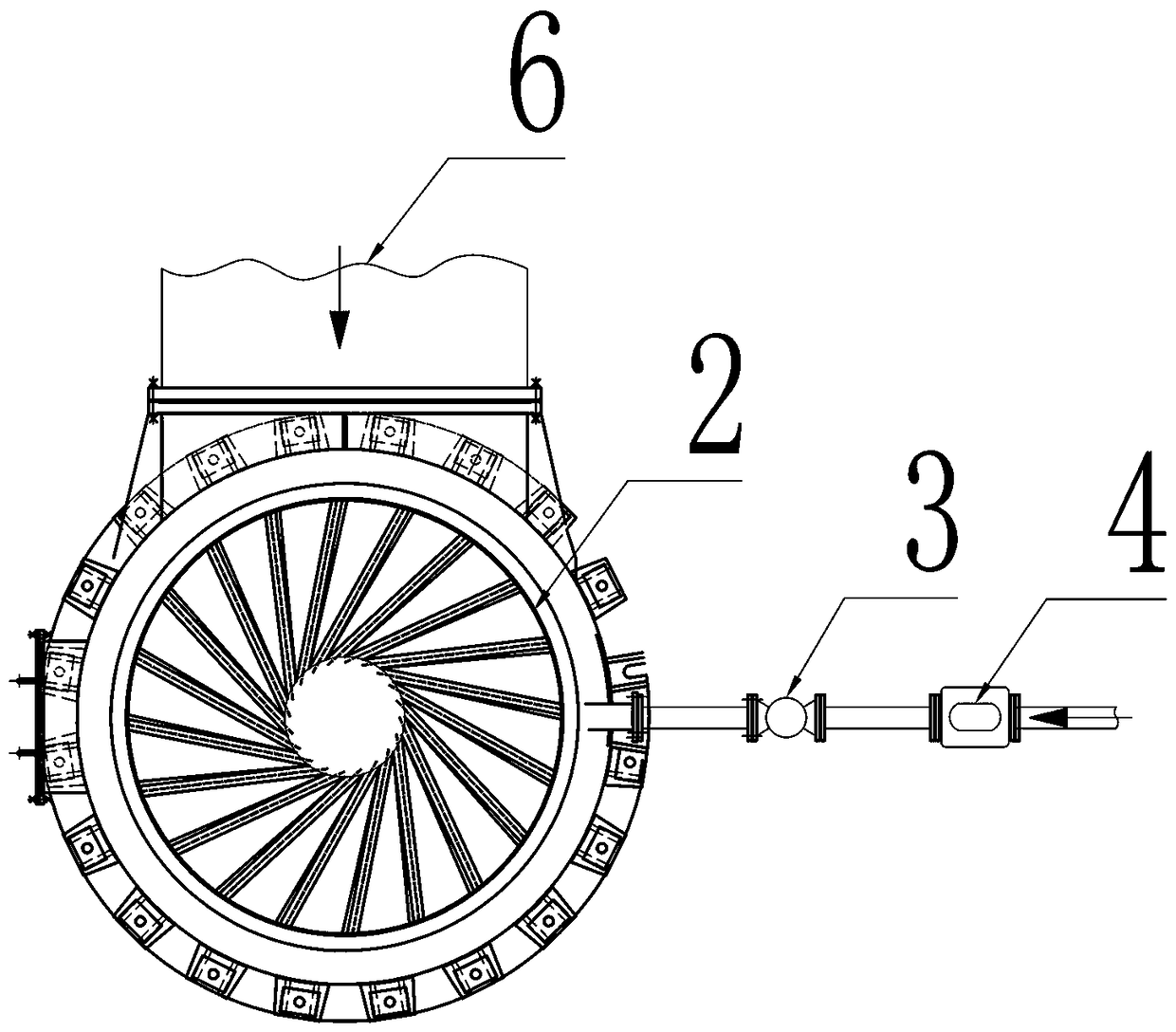

[0041] 1) After the PVC resin drying system is started, firstly adjust the air intake of the tail gas scrubber to 80,000m³ / h, and adjust the temperature of the PVC resin drying system to the process control value. At this time, the inlet temperature of the tail gas scrubber is 35°C, and the exhaust gas The dust content in it is 0mg / m³. The dust-laden exhaust gas enters the body of the scrubber from the air inlet, and flows upward evenly from the bottom of the exhaust scrubber after being deflected by the elbow at the inlet.

[0042] 2) The spray water of the spray coil of the tail gas scrubber is cut to the primary water, and the water temperature of the primary water is adjusted to 25°C. The suspended solids are washed down, and the washed tail gas continues to rise after passing through the spray coil and reaches the position of the swirl plate.

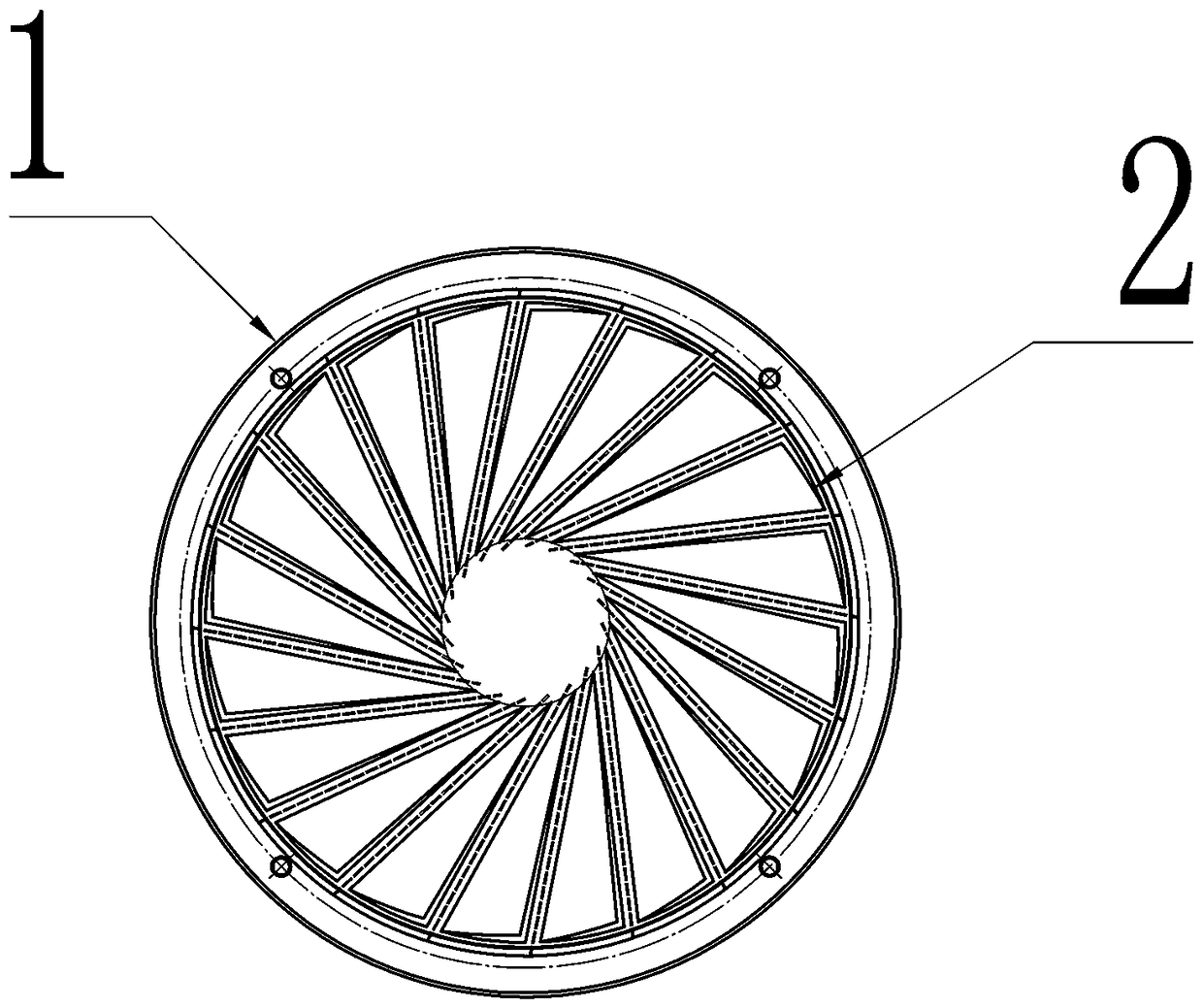

[0043]3) The remaining solid suspended solids and water vapor mixture in the dusty tail gas are guided and separated by the swir...

Embodiment 2

[0045] 1) After the PVC resin drying system is started, firstly adjust the air intake of the tail gas scrubber to 80,000m³ / h, and adjust the temperature of the PVC resin drying system to the process control value. At this time, the inlet temperature of the tail gas scrubber is 75°C, and the exhaust gas The dust content in the container is 25mg / m³. The dust-laden exhaust gas enters the body of the scrubber from the air inlet, and flows upward evenly from the bottom of the exhaust scrubber after being deflected by the elbow at the inlet.

[0046] 2) The spray water of the spray coil of the tail gas scrubber is cut to the primary water, and the water temperature of the primary water is adjusted to 25°C. The suspended solids are washed down, and the washed tail gas continues to rise after passing through the spray coil and reaches the position of the swirl plate.

[0047] 3) The remaining solid suspended solids and water vapor mixture in the dusty tail gas are guided and separate...

Embodiment 3

[0049] 1) After the polyvinyl chloride resin drying system is started, firstly adjust the air intake of the tail gas scrubber to 80,000m³ / h, and adjust the temperature of the polyvinyl chloride resin drying system to the process control value. The dust content in it is 5mg / m³. The dust-laden exhaust gas enters the body of the scrubber from the air inlet, and flows upward evenly from the bottom of the exhaust scrubber after being deflected by the elbow at the inlet.

[0050] 2) The spray water of the spray coil of the tail gas scrubber is cut to the primary water, and the water temperature of the primary water is adjusted to 35°C. The suspended solids are washed down, and the washed tail gas continues to rise after passing through the spray coil and reaches the position of the swirl plate.

[0051] 3) The remaining solid suspended solids and water vapor mixture in the dusty tail gas are guided and separated by the swirl plate and then rotate along the tower wall and continue t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com