Ionic liquid-based efficient flocculating agent for drilling fluid

A technology of ionic liquid and water-based drilling fluid, which is applied in the field of oil and gas drilling, can solve the problems of poor flocculation effect of submicron cuttings and inferior soil, and the inability to efficiently remove submicron cuttings and inferior soil, so as to promote reuse , resource utilization long-term, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

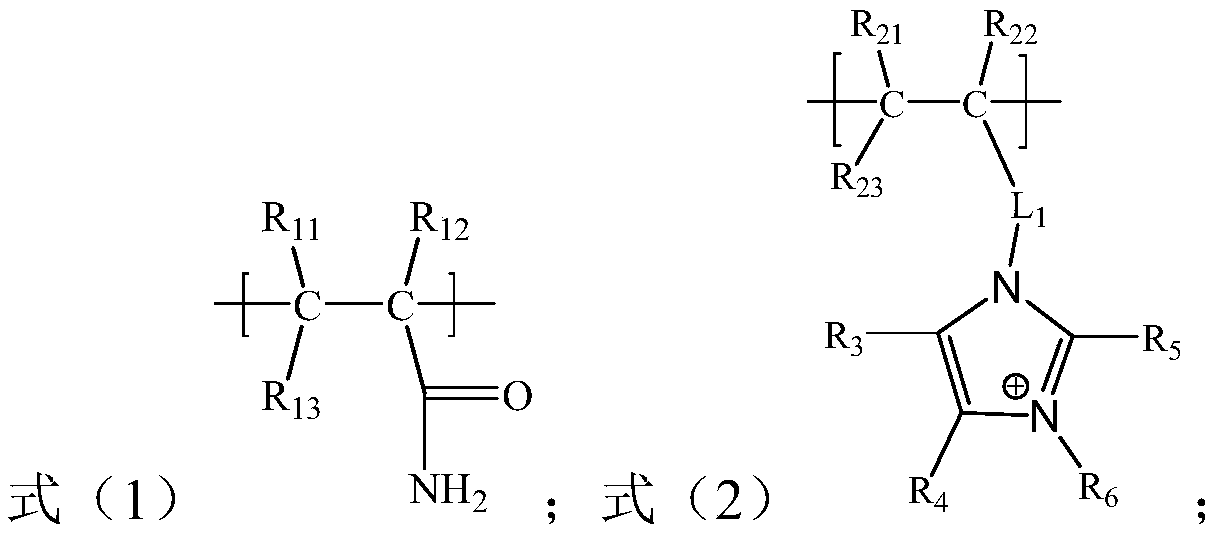

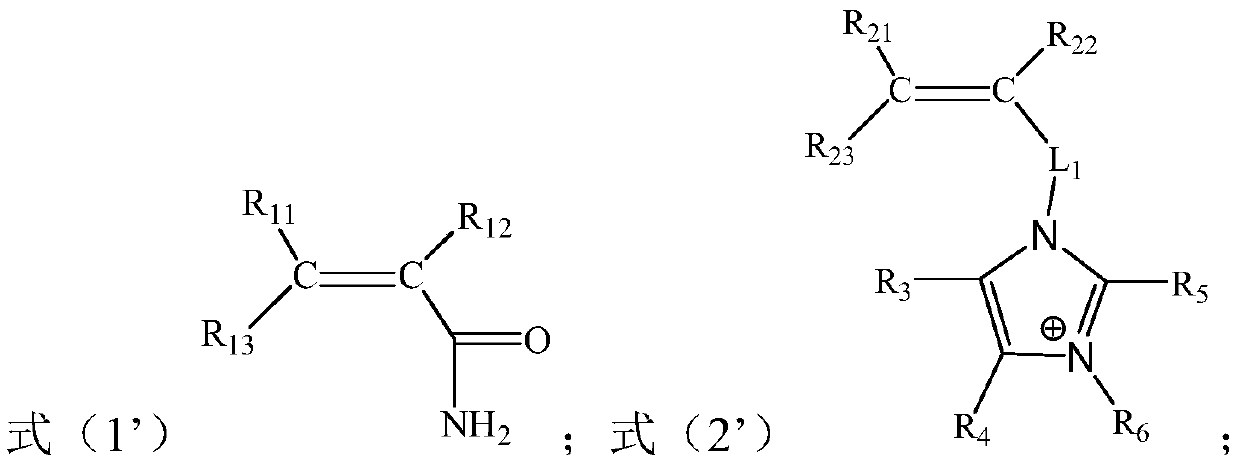

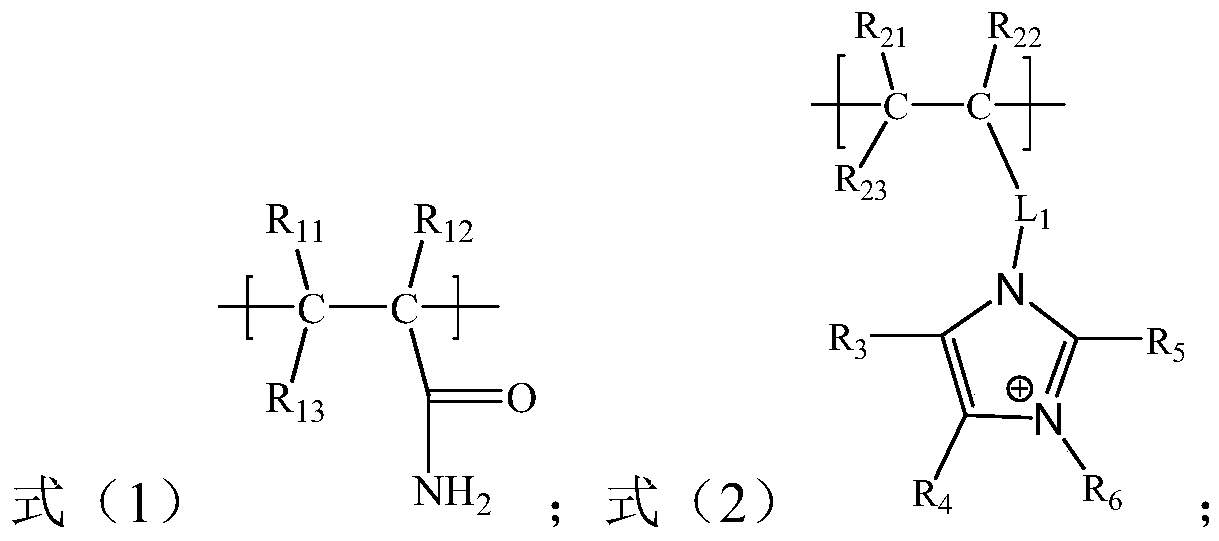

[0039] The second aspect of the present invention provides a method for preparing an acrylamide copolymer suitable for use as a flocculant or its hydrolyzate, the method comprising: in the presence of an initiator, in an aqueous solvent, the The monomer and the imidazole ionic liquid carry out a copolymerization reaction; the cationic part of the imidazole ionic liquid has a structure shown in formula (2');

[0040]

[0041] Among them, R 11 -R 13 , R 21 -R 23 and R 3 -R 5 each independently selected from H and C1-C6 alkyl; R 6 Alkyl selected from C1-C6; L 1 is a link or a C1-C6 alkylene group.

[0042] According to the present invention, R 11 -R 13 , R 21 -R 23 , R 3 -R 5 and L 1 As introduced above, details will not be repeated here.

[0043] According to the present invention, the monomer represented by the formula (1') will provide the structural unit represented by the formula (1) described above for the obtained acrylamide copolymer, and the cationic pa...

Embodiment 1

[0074] This example is used to illustrate the acrylamide copolymer of the present invention and its preparation method.

[0075] Add 282mmol of acrylamide and 29mmol of vinylimidazole ionic liquid VM1 (purchased from Lanzhou Zhongke Kite Technology Industry and Trade Co., Ltd.) into 100mL of deionized water, and stir for 10 minutes to dissolve. Nitrogen gas was slowly introduced for 10 minutes, followed by adding 0.35 mmol of potassium persulfate and 0.35 mmol of sodium bisulfite, and reacted at 60°C for 5 hours to obtain a gel-like product, which was then dried and ground to obtain acrylamides Copolymer as flocculant PAV-1.

[0076] The weight average molecular weight of the acrylamide-based copolymer was 2.6 million g / mol.

Embodiment 2

[0078] This example is used to illustrate the acrylamide copolymer of the present invention and its preparation method.

[0079] Add 211mmol of acrylamide and 58mmol of vinylimidazole ionic liquid VM1 (purchased from Lanzhou Zhongke Kite Technology Industry and Trade Co., Ltd.) into 100mL of deionized water, and stir for 10 minutes to dissolve. Nitrogen gas was slowly introduced for 10 minutes, followed by adding 0.37mmol of potassium persulfate and 0.48mmol of sodium bisulfite, and reacted at 50°C for 6h to obtain a gel-like product, which was then dried and ground to obtain acrylamides Copolymer as flocculant PAV-2.

[0080] The weight average molecular weight of the acrylamide copolymer is 3.5 million g / mol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com