Semiconductor laser diode with low threshold current

A technology of laser diodes and semiconductors, applied in semiconductor lasers, optical waveguide semiconductor structures, lasers, etc., can solve the problems of laser diode threshold current reduction, affecting hole injection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention provides an active region of a semiconductor laser diode (eg, III-nitride-based laser light emitting diode). The active region may include two quantum well regions, wherein the quantum well closest to the n-side semiconductor has an increased bandgap compared to the quantum well closest to the p-side semiconductor. Devices including multiple quantum well structures for active regions can provide low threshold currents, long lifetimes, and high socket conversion efficiencies.

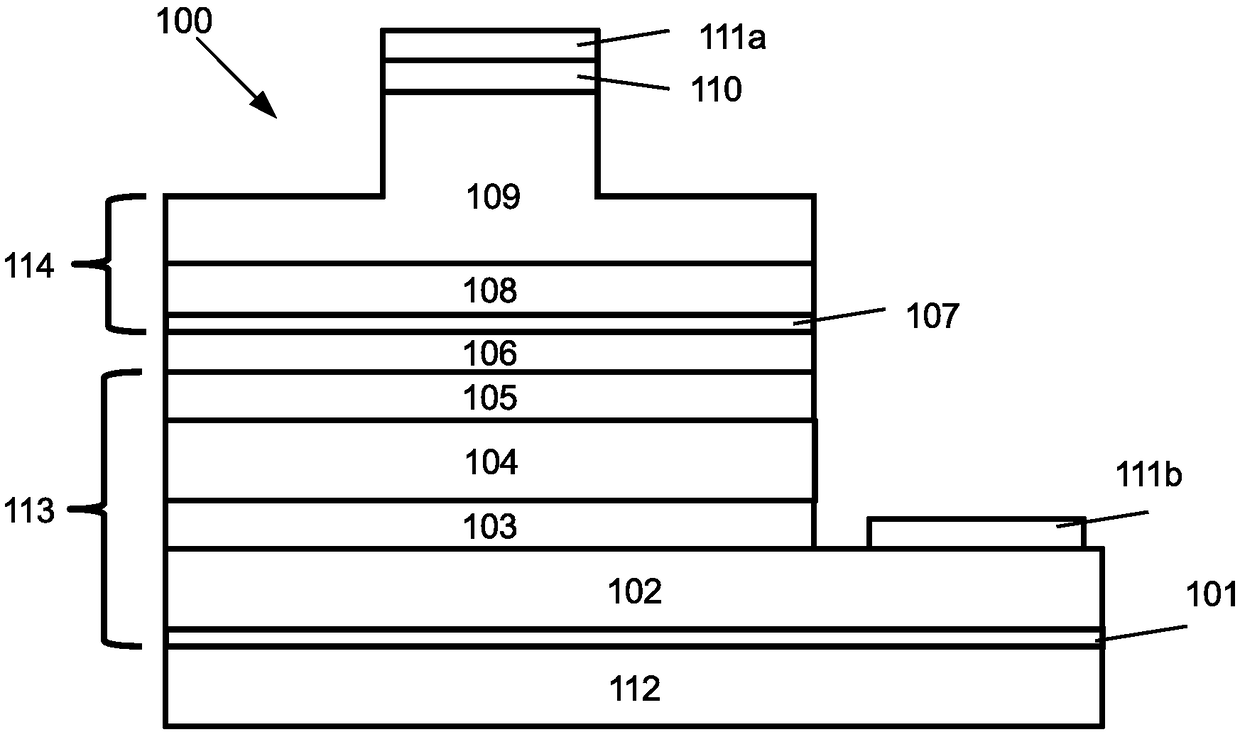

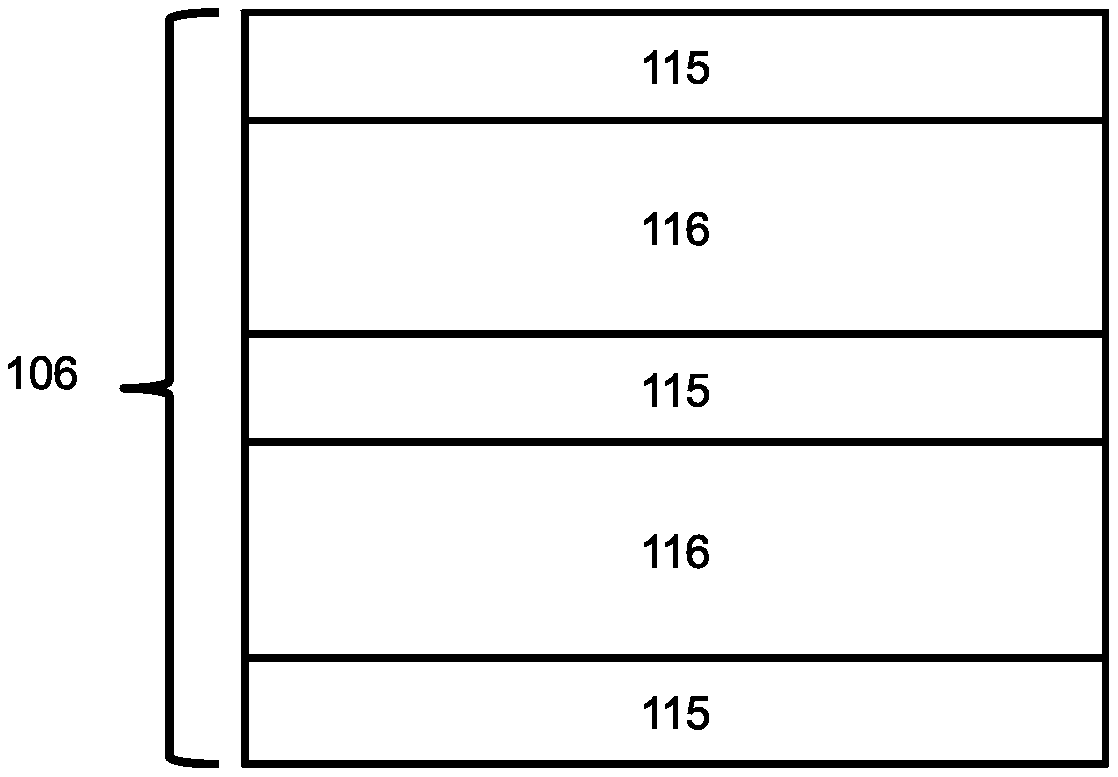

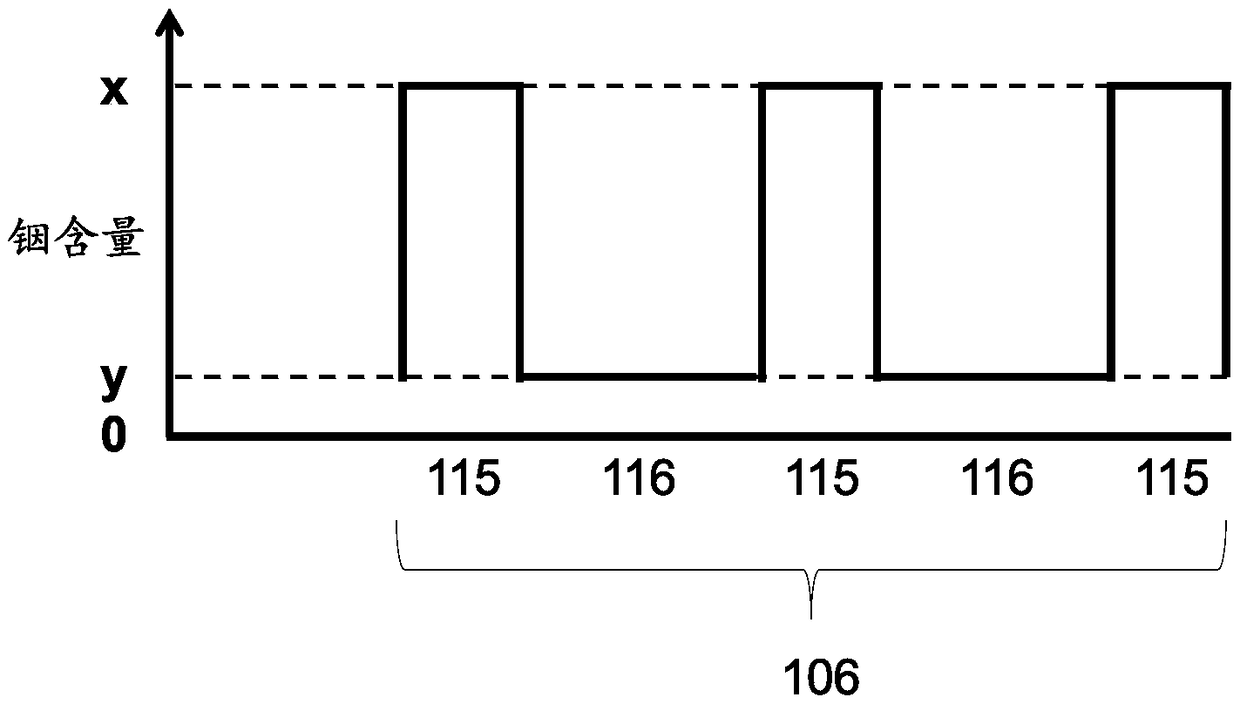

[0059] now refer to Figure 2A and Figure 2B , 200 illustrates an exemplary embodiment of a semiconductor laser diode (eg, Ill-nitride-based laser light emitting diode) device including an active region. The III-nitride-based laser light-emitting diode device includes an n-side (III-nitride-based) semiconductor region 212, a p-side (III-group nitride-based) semiconductor region 213, and a p-side semiconductor region 213 and n (Ill-nitride based) active region 204 between ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com