Method for in-situ exploitation of oil shale

An in-situ mining and oil shale technology, which is applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of unsuitability for oil shale production, kerogen needs to be improved, and electric heating time is long. Achieve the effect of economical and efficient mining, small size and improved conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0037] According to one embodiment, the proppant containing magnetic nano-catalyst is prepared by the following method:

[0038] a. Contact the mixed solution of ferric salt and ferrous salt with alkaline aqueous solution to form Fe through hydrolysis and crystallization 3 o 4 particle;

[0039] b. Fe 3 o 4 Particles as carriers, in the Fe 3 o 4 supporting the transition metal on the particles to prepare supported catalyst particles;

[0040] c. ultrasonically stirring the supported catalyst particles in water for 0.5-2 hours, so that the particles are evenly dispersed in water to obtain the first dispersion system;

[0041] d. Mix the first dispersion system with the proppant, and ultrasonically stir for 0.5-2 hours to obtain the second dispersion system;

[0042] e. Centrifuge the second dispersion system, and heat the solid obtained after centrifugation at 150-200° C. for 5-10 hours to obtain the proppant containing the magnetic nano-catalyst.

[0043]In step a, the...

Embodiment

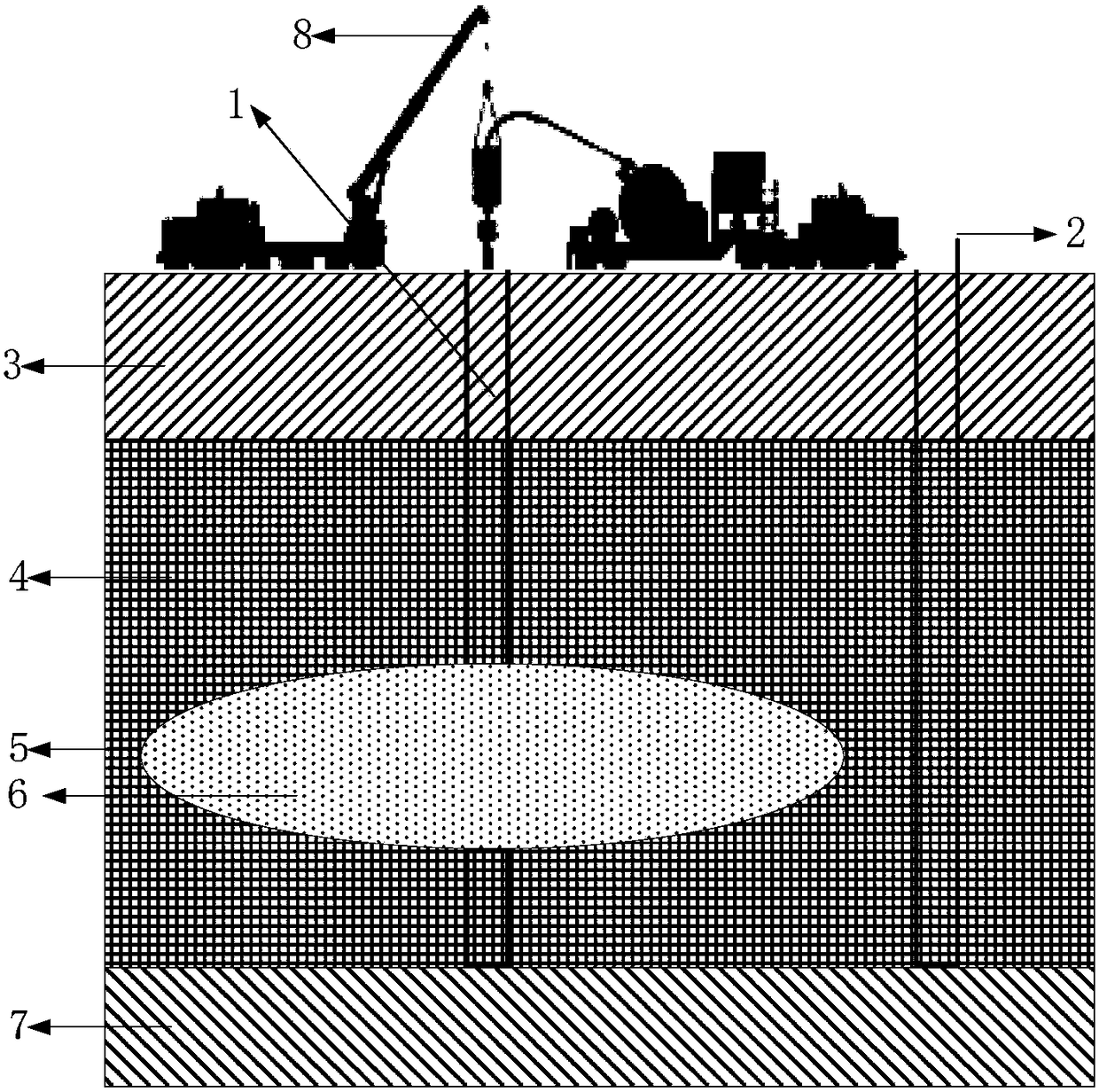

[0054] The method for in-situ mining of oil shale in this embodiment is as follows: figure 1 shown.

[0055] The oil shale in a certain place is deeply buried, generally 300-500m, and must be exploited underground. The average thickness of the oil shale reservoir 4 is about 26m, the average oil content is as high as 13%, and the total water content is 4%. The method specifically includes:

[0056] (1) Drill two vertical wells from the surface of the oil shale distribution area to penetrate the oil shale reservoir 4: one is a heating well 1 and the other is a production well 2, and the spacing between the wells is about 50m, and they are completed with casing;

[0057] (2) Preparation of magnetic nanoparticles by hydrolysis: ferric salt (Fe 3+ ) and ferrous salt (Fe 2+ ) is directly added to ammonia water, and the iron salt is instantly hydrolyzed and crystallized to form Fe 3 o 4 Nanoparticles (average particle size is 250nm);

[0058] (3) with the Fe 3 o 4 Nanoparticl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Pyrolysis temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com