Ultrasonic impact surface modification auxiliary titanium alloy diffusion connection method

A technology of ultrasonic impact and diffusion connection, applied in the field of diffusion connection, can solve the problems of complex process, poor applicability, complicated operation, etc., and achieve the effect of simple structure, convenient operation, and accelerated diffusion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

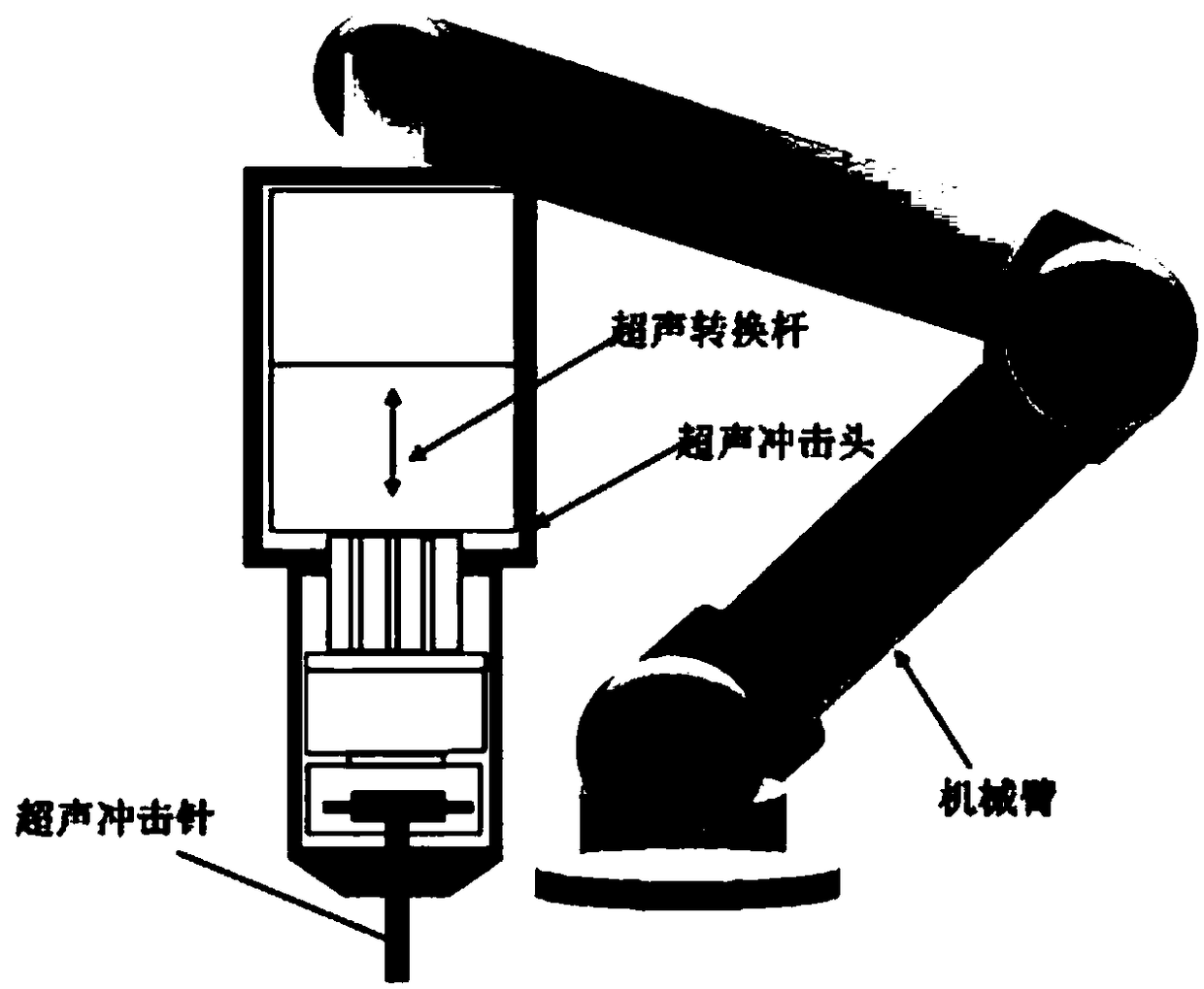

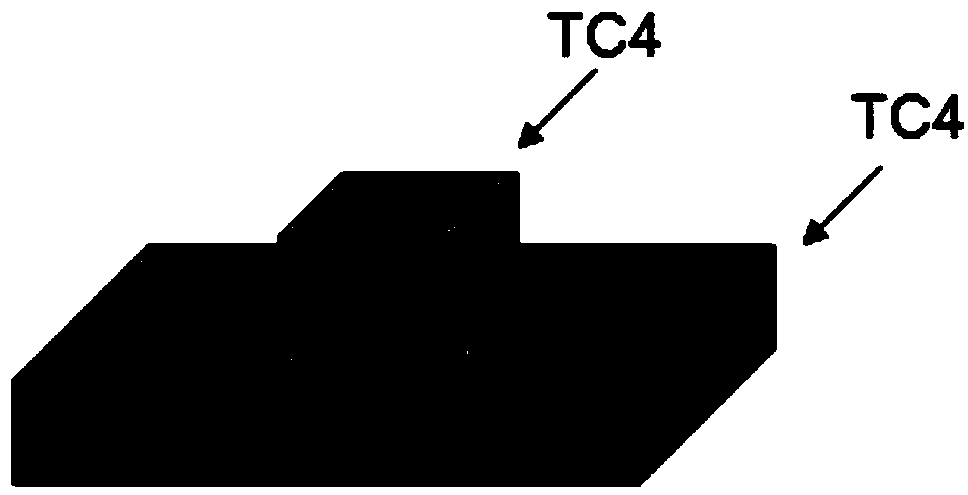

[0026] use attached figure 1 The ultrasonic impact equipment shown is for ultrasonic impact of titanium alloy. It is preferable to use a spherical impact head or a needle-shaped impact head with the same material as the titanium alloy. The ultrasonic impact equipment is selected as the full-wavelength type. Equipment to realize the movement and control of the ultrasonic impact head in three dimensions. as attached figure 2 As shown in Fig. 1, the titanium alloy surface after ultrasonic shock was bonded for diffusion bonding.

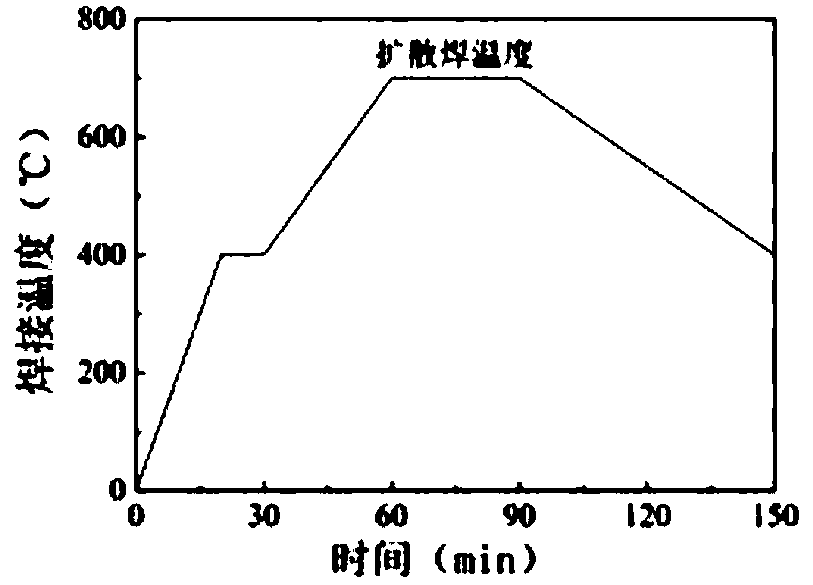

[0027] In this example, the ultrasonic shock frequency of TC4 plate is 17.7kHz, the current is set to 3A, the amplitude is 40μm, the diameter of the ultrasonic shock needle is 4mm, the walking speed is 1mm / s, and the number of shocks is 1 pass. for surface modification. Then process the plate into small pieces of 5mm×5m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com