Combined method for recycling flue gas desulfurization and fuel gas deamination pollutants and treating waste by using waste

A technology for treating waste and pollutants with waste, applied in the direction of chemical instruments and methods, separation methods, educts, etc., can solve problems such as secondary pollution with negative benefits, and achieve reliable operation, mature technology, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

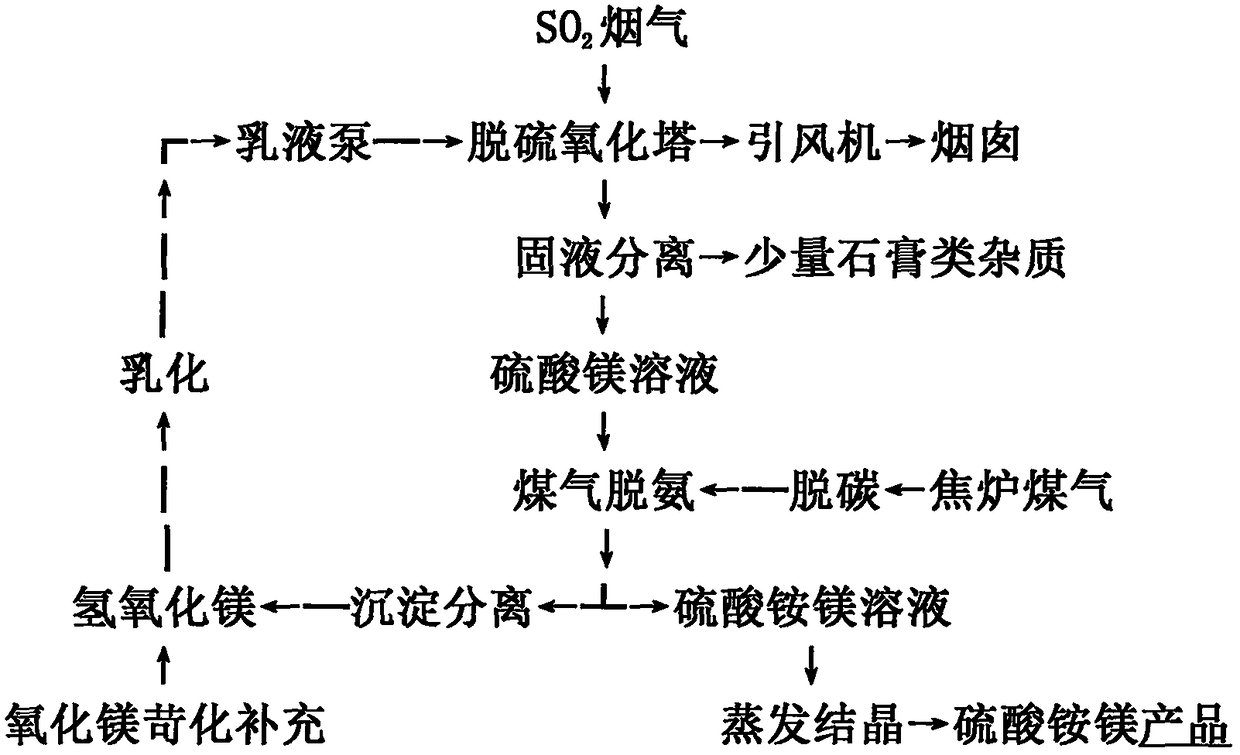

[0088] This embodiment provides a combined method for recycling flue gas desulfurization and gas deammoniation pollutants to waste treatment, including the following steps:

[0089] (1) Pass the sulfur dioxide-containing flue gas and oxidizing air to be treated from the bottom of the desulfurization oxidation tower and go up at a low speed, and fully react with the magnesium hydroxide emulsion sprayed on the top of the tower in an oxidizing atmosphere to generate magnesium sulfite and calcium sulfite , and then oxidized to magnesium sulfate and calcium sulfate;

[0090] The magnesium hydroxide emulsion is obtained through hydrolysis and emulsification processing in an emulsification tank with magnesium oxide as a raw material;

[0091] (2) the reaction product obtained in step (1) is subjected to solid-liquid separation to obtain magnesium sulfate solution and a small amount of gypsum impurities;

[0092] (3) The magnesium sulfate solution obtained in step (2) is sent to the ...

Embodiment 2

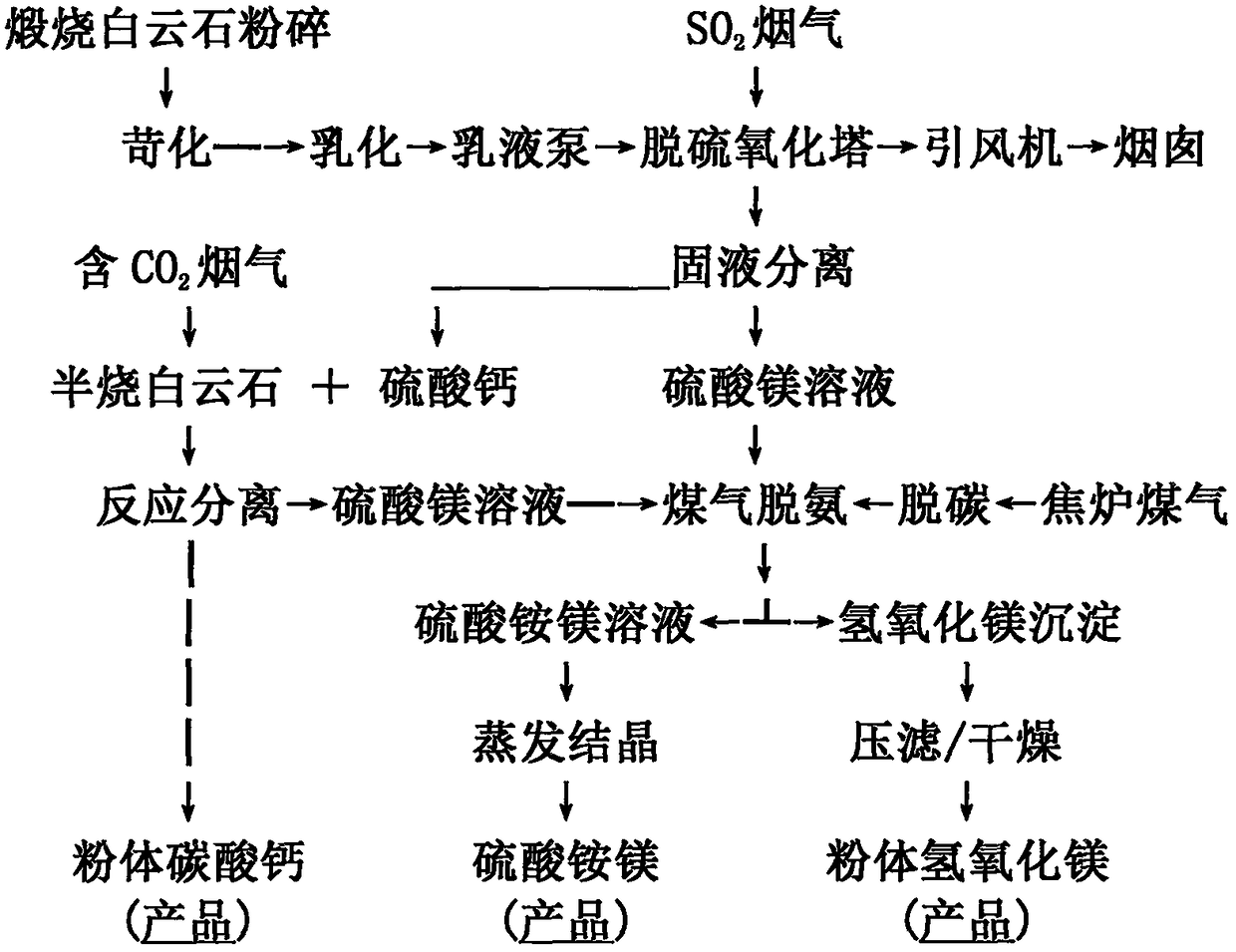

[0097] This embodiment provides a combined method for resource utilization of flue gas desulfurization and gas deammoniation pollutants to waste treatment, specifically:

[0098] (1) Pass the sulfur dioxide-containing flue gas and oxidizing air to be treated from the bottom of the desulfurization oxidation tower and go up at a low speed, and fully react with the mixed emulsion of magnesium hydroxide and calcium carbonate sprayed on the top of the tower to generate magnesium sulfite and calcium sulfite , and then oxidized to magnesium sulfate and calcium sulfate;

[0099] The mixed emulsion of magnesium hydroxide and calcium carbonate is obtained by processing dolomite powder as raw material after hydrolysis and emulsification;

[0100] (2) carrying out solid-liquid separation with the easily water-soluble magnesium sulfate of step (1) gained reaction product and the insoluble calcium sulfate, obtain magnesium sulfate solution and powder calcium sulfate;

[0101] (3) The magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com