Feeding machine with barometric columns and lift-drop control mechanism

A lift control and feeder technology, applied in the field of feeders, can solve the problems of having to open the box for cleaning, affecting the survival of abalone, and existing errors, and achieve the effect of consistent and accurate feeding amount, clean and fast delivery, and accurate measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present application will be further described in detail through the following embodiments in conjunction with the accompanying drawings. Apparently, the described embodiments are only part of the embodiments of the present application.

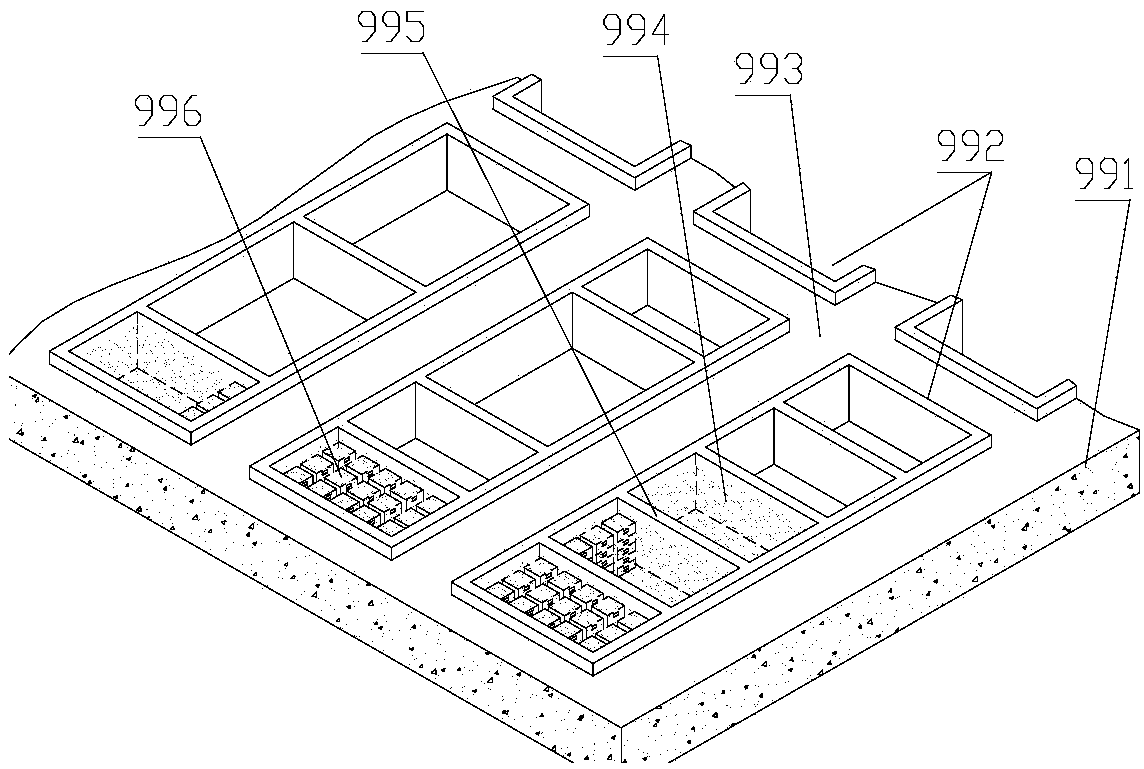

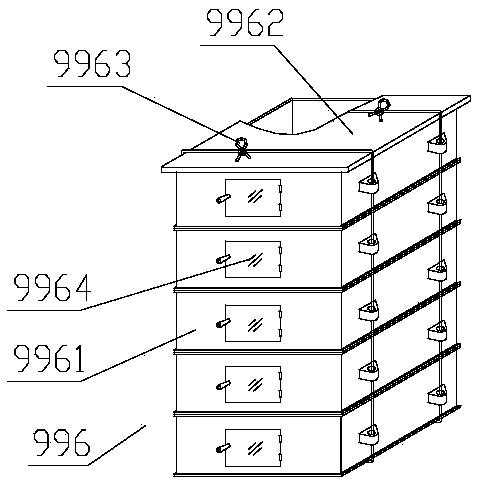

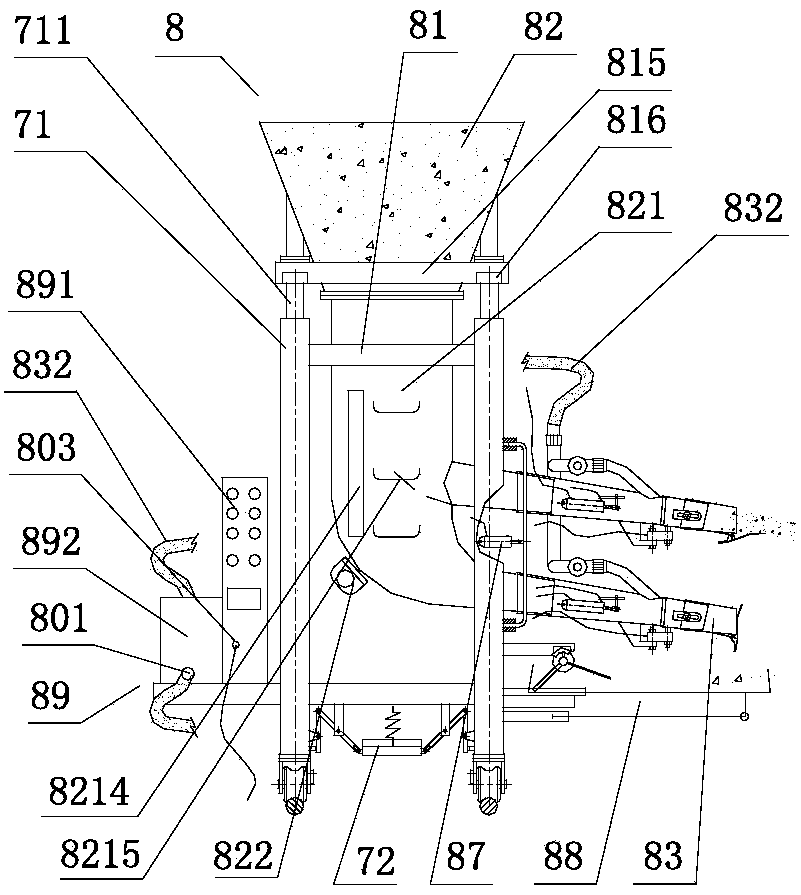

[0036] Such as image 3 , Figure 4 , Figure 5 As shown, it is a front view, a side view, and a partial enlarged view of a feeder with a pneumatic column and a lifting control mechanism according to the first embodiment of the application. The feeder 8 includes a frame 81, a silo 82, and a hopper. 821, material spraying pipe 83, material spraying pipe lateral adjustment device 87, leaking material receiving device 88, lifting control mechanism 72, weighing system 80, control system 89; said frame 81 is provided with air pressure column 71, said air pressure The column can control the expansion and contraction of the piston rod 711 on the air pressure column through the internal high-pressure gas, thereby...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com