Storage battery pole sealing method

A battery and pole technology, which is applied in the field of battery pole sealing, can solve problems such as liquid leakage, accidents, and electrical insulation failure, and achieve the effects of simple process, liquid leakage prevention, and improved liquid tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

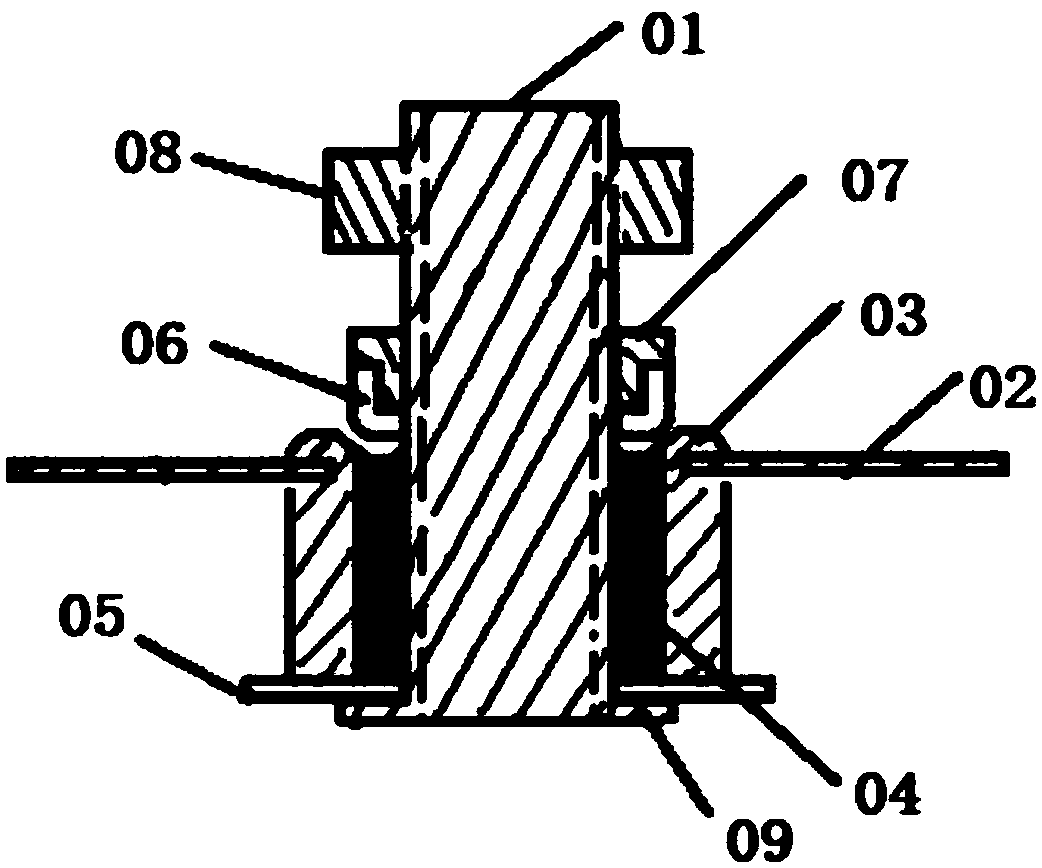

Method used

Image

Examples

Embodiment 1

[0023] (Embodiment 1): The present embodiment will be described with reference to packaging as a pole of a lithium ion storage battery.

[0024] A. Positive sheet production

[0025] The positive electrode material is scaled (LiCoO 2 :Super P:PVDF=93:4:3), mixed with NMP (NMP: weight of solid matter=810:1500), and the viscosity of the positive electrode slurry was controlled at 6000cps. The positive electrode slurry is evenly coated on the surface of the aluminum foil, and the positive electrode sheet is made by drying, rolling, and cutting to the designed process parameters.

[0026] B. Negative sheet production

[0027] Mix the negative electrode material in proportion (C:Super P:SBR:CMC=94:1:2.5:2.5), and mix with H 2 O(H 2 O: weight of solid matter=1600:1420) for mixing and stirring, and the viscosity of the negative electrode slurry is controlled at 5000-6000 cps. The negative electrode slurry is evenly coated on the surface of the copper foil, and the negative elect...

Embodiment 2

[0045] (Embodiment 2): This embodiment will be described with reference to the post package as a nickel-metal hydride storage battery.

[0046] A. Positive sheet production

[0047] The positive electrode material is mixed and stirred according to the ratio (nickel hydroxide:CoO:PTFE:HPMC=50:5:2:9), and the viscosity of the positive electrode slurry is controlled at 10000cps-12000cps. The positive electrode slurry is evenly coated on the surface of nickel foam, and the positive electrode sheet is made by drying, rolling, and cutting to the designed process parameters.

[0048] B. Negative sheet production

[0049] The negative electrode material is mixed and stirred according to the ratio (MH:acetylene black:PTFE:CMC=50:1:1:8), and the viscosity of the negative electrode slurry is controlled at 15000cps-16000cps. The negative electrode slurry is evenly coated on the surface of the perforated nickel-plated steel strip, and the negative electrode sheet is made by drying, rolli...

PUM

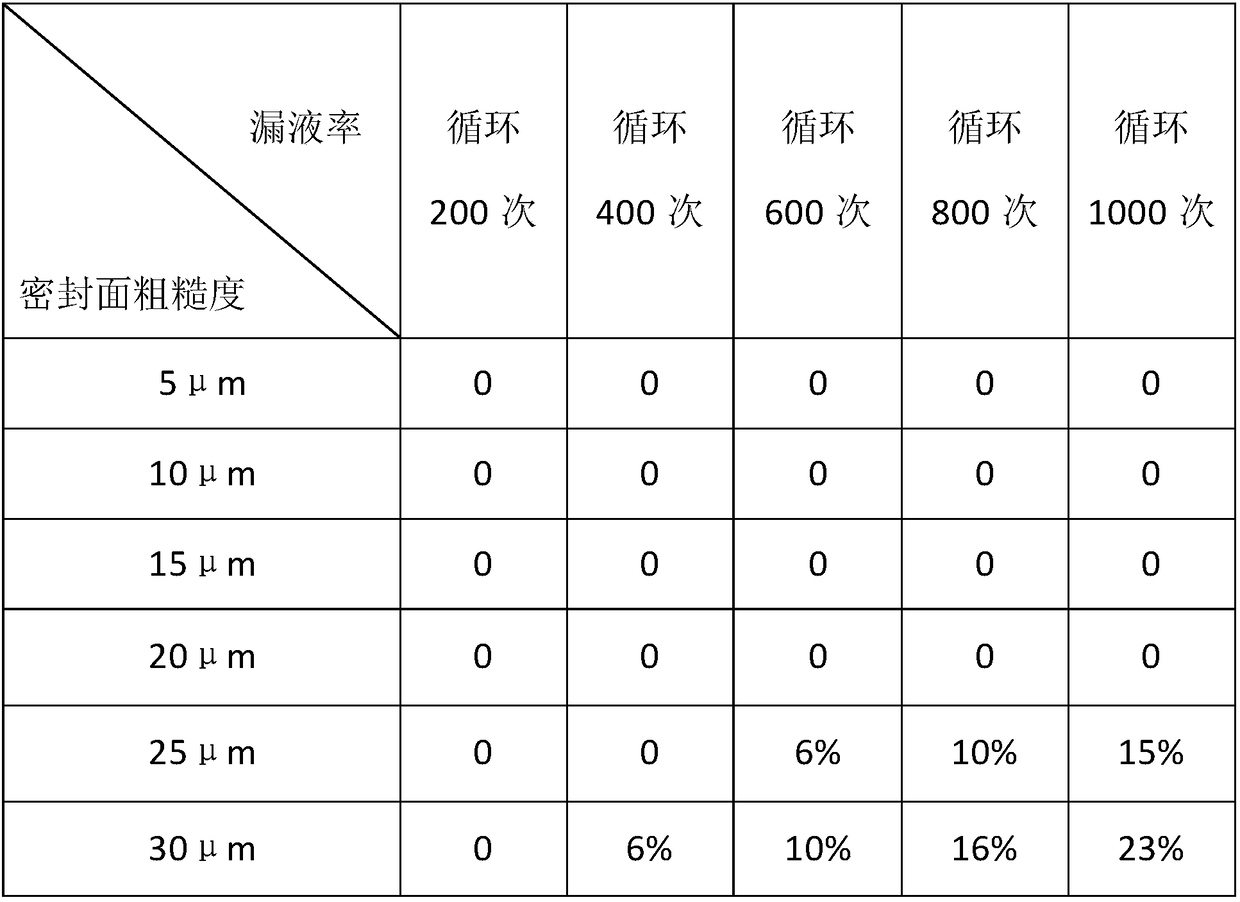

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com