A two-stage high temperature condensation heat recovery heat pump system

A high-temperature condensation and heat pump system technology, which is applied in the field of condensation heat recovery heat pump and double-stage high-temperature condensation heat recovery heat pump system, can solve the problems of large irreversible loss of the system, large temperature difference between cold and heat of the condensing evaporator, and poor adjustability. The contradiction between heat supply and demand, ensuring the heating temperature and the effect of heat supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

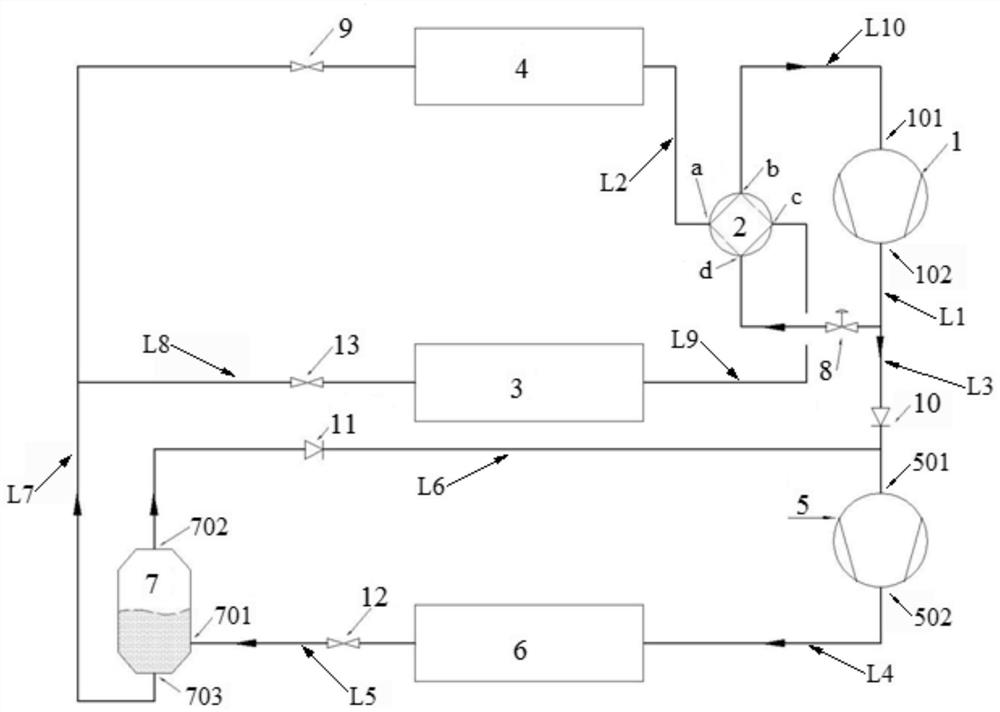

[0060] Such as figure 1 As shown, a two-stage high-temperature condensation heat recovery heat pump system includes a low-pressure compressor 1, a four-way valve 2, an indoor heat exchanger 3, an outdoor heat exchanger 4, a high-pressure compressor 5, a high-temperature water heater 6, and a gas-liquid Separator 7. Wherein, the first pipeline L1 drawn from the discharge port 102 of the low-pressure compressor 1 is connected to the port d of the four-way valve 2 . The a port of the four-way valve 2 is connected to one end of the outdoor heat exchanger 4 via the second pipeline L2. The third pipeline L3 branched from the first pipeline L1 is connected to the suction port 501 of the high-pressure compressor 5 . The exhaust port 502 of the high-pressure compressor 5 is connected to the inlet of the high-temperature water heater 6 via a fourth pipeline L4. The fifth pipeline L5 drawn from the outlet of the high-temperature water heater 6 is connected to the inlet 701 of the gas-...

Embodiment 2

[0072] Under summer working conditions, the two-stage high-temperature condensation heat recovery heat pump system of the present invention is used as a summer refrigeration cycle system to realize partial high-temperature condensation heat recovery working conditions: the first throttle valve 9 is fully open, the normally open solenoid valve 8 is not powered, and the low-pressure compressor One way of the exhaust gas of 1 flows to the outdoor heat exchanger 4 to condense through the solenoid valve 8, the d end of the four-way valve 2, and the a end of the four-way valve 2; the other way flows through the first one-way valve 10 to the high-pressure compressor Compressed again in 5, the exhaust gas from high-pressure compressor 5 is condensed in high-temperature water heater 6, and the liquid working medium discharged from high-temperature water heater 6 is throttled by second throttle valve 12, flashed and separated in gas-liquid separator 7, and saturated The gas working medium ...

Embodiment 3

[0074] In summer working conditions, the two-stage high-temperature condensation heat recovery heat pump system of the present invention is used as a summer refrigeration cycle system to realize full-heat high-temperature condensation heat recovery working conditions: the normally open solenoid valve 8 is energized and closed, the first throttle valve 9 is closed, and the low-pressure compressor The exhaust of 1 flows through the first one-way valve 10 to the high-pressure compressor 5 to be compressed again, the exhaust of the high-pressure compressor 5 is condensed in the high-temperature water heater 6, and the liquid working medium discharged from the high-temperature water heater 6 passes through the second throttle valve 12 After throttling, it flashes and separates in the gas-liquid separator 7, and the saturated gas working medium flows through the second check valve 11 and returns to the high-pressure compressor 5, and the saturated liquid working medium is throttled by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com