A kind of domestication method of industrial saccharomyces cerevisiae

A technology for Saccharomyces cerevisiae and Saccharomyces cerevisiae, which is applied in the fields of bioengineering and microorganisms, can solve the problems of inability to improve the high-concentration ethanol tolerance of yeast strains, limited domestication and cultivation time, etc., and achieves strong wine-producing ability, good reproducibility, The effect of rapid growth and reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

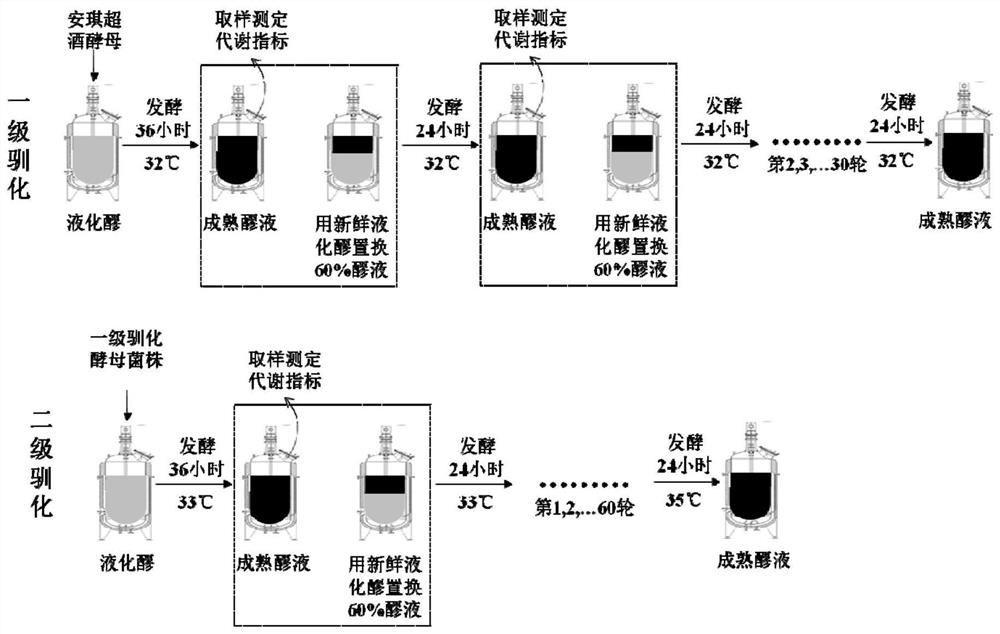

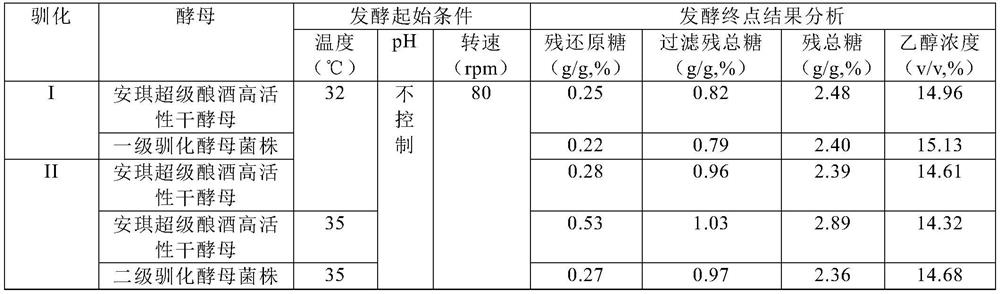

Embodiment 1

[0086] Angel super brewing highly active dry yeast (production batch number: cy80081) was purchased from Angel Yeast Co., Ltd. The substrate used in the domestication process and brewer's culture was corn flour liquefied mash, and the dry solid was 30wt%. The acclimation process was carried out in a benchtop fermenter (Shanghai Baoxing, BIOTECH 2JG) with a total volume of 3 L.

[0087] Liquefied corn mash is to mix corn flour with water in a mass ratio of 1:2 into a uniform slurry and pre-cook the temperature to make the starch swell by water absorption, heat it to 85±1 °C, stay for 30 minutes, add amylase at the temperature It was obtained by liquefaction at 85°C for 3 hours. The liquefied corn mash contained 125,000 U / kg (mash) saccharification enzyme, 03,500 U / kg (mash) acid protease and 3 ppm penicillin.

[0088] (1) Weigh 10g of Angel Super Brew high-activity dry yeast and add it to 200mL of sterile water, activate at 30°C for 30 minutes.

[0089] (2) Press 1.3-1.5×10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com