Formula and preparation method of one-component aromatic polyurea coating

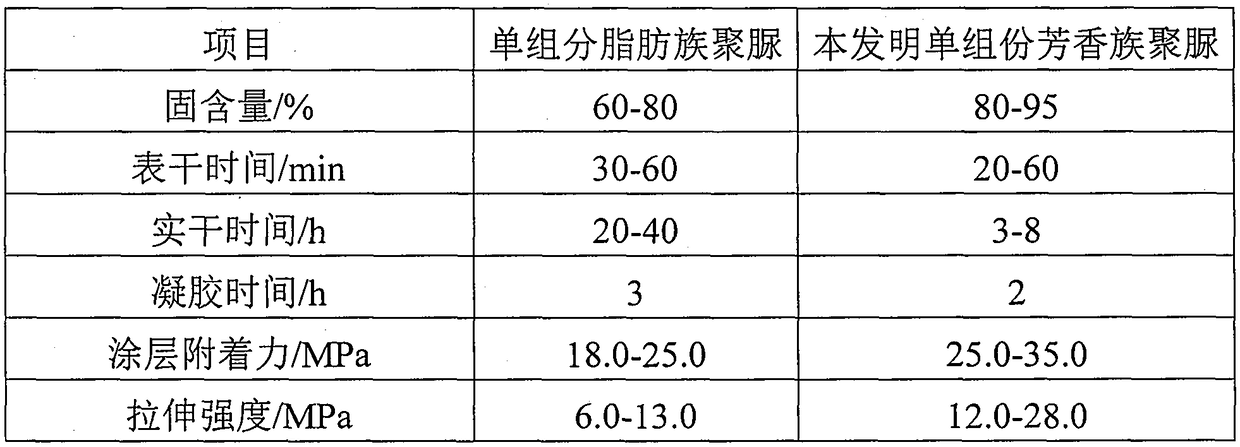

An aromatic, one-component technology, used in polyurea/polyurethane coatings, fire-retardant coatings, coatings, etc., can solve the problems of poor storage stability, low tensile strength and elongation, limited application areas, etc., and achieve stable performance. , the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A single-component aromatic polyurea coating formula and its preparation method In the formula described in the formula, unless otherwise specified, the percentages in the present invention are all mass percentages.

[0052] Toluene diisocyanate / diphenylmethane diisocyanate 20-40%, adipic acid polyester diol (molecular weight 2000) 15-25%, trifunctional polyether diol 5-10% (molecular weight 400), poly Tetrahydrofuran dibasic ether (molecular weight 1000) 20-25%; 1,4-butanediol 3-5%; JH-306 ketimine (molecular weight 320) 10-15%; dibutyltin dilaurate 0.1-0.5% , Aromatic oil 5-20%.

[0053] S1, first put 13.2g adipic acid polyester diol (molecular weight 2000), 2.6g trifunctional polyether diol (molecular weight 400) and 29.7g polytetrahydrofuran divalent ether (molecular weight 1000) into the stirring In a four-necked flask reactor including a reactor, a thermometer, a dropping funnel, and a reflux condenser. Turn on the vacuum pump to vacuumize the four-neck flask reactor...

Embodiment 2

[0063] Naphthalene diisocyanate (molecular weight 210) 20-40%, isophthalic acid diol (molecular weight 2000) 10-20%, trifunctional polyether diol 5-10% (molecular weight 400), polytetrahydrofuran binary Ether (molecular weight 1000) 20-40%; 1,4-butanediol 3-5%; ketimine JH-306 (molecular weight 320) 10-15%; dibutyltin dilaurate 0.1-0.5%, aromatic oil 5-20%.

[0064] S1, first put 9.4g isophthalic diol (molecular weight 2000), 2.4g trifunctional polyether diol (molecular weight 400) and 29.7g polytetrahydrofuran dihydric ether (molecular weight 1000) into the mixer , Thermometer, dropping funnel, reflux condenser tube in a four-necked flask reactor. Turn on the vacuum pump to vacuumize the four-neck flask reactor, and maintain the vacuum degree of the four-neck flask reactor above -0.095MPa. Use oil bath or water bath heating method to heat the materials in the four-neck flask reactor to 110°C and keep the temperature between 110-120°C, vacuum and keep the temperature for 2h. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

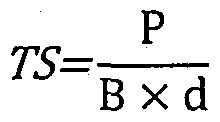

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com