Waterborne interference type pearly flashing paint for automobile and preparation method of waterborne interference type pearly flashing paint

An interference type, flash paint technology, used in coatings, anti-corrosion coatings, etc., can solve problems such as insufficient corrosion resistance, paint film loss, graining, etc., to promote solvent evaporation, gorgeous and soft gloss, and promote directional alignment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 The preparation of self-thickening acrylic acid emulsion

[0039] (1) Take 2g of sodium dodecylbenzenesulfonate, dissolve it in 20g of deionized water, and add 55g of methyl methacrylate and 23g of butyl acrylate dropwise under stirring at a speed of 1000rpm. Stir for 1 h after the addition to obtain a core layer pre-emulsion;

[0040] (2) Get 2g of sodium dodecylbenzene sulfonate, dissolve it in 20g of deionized water, and add dropwise 12g of methacrylic acid, 40g of hydroxyethyl methacrylate and 26g of butyl acrylate under stirring at a speed of 1000rpm Esters, after 0.5h dropwise, stir for 1h after the dropwise addition, to obtain the shell layer pre-emulsion;

[0041] (3) Add 40g of deionized water and 0.2g of sodium dodecylbenzenesulfonate under nitrogen protection into a four-necked flask equipped with an agitator, a condenser, and a two-port connecting pipe, stir well, and place in a constant temperature water bath Heating to 80° C., adding dropwis...

Embodiment 2

[0044] Embodiment 2 The preparation of self-thickening acrylic acid emulsion

[0045] (1) Take 3g of sodium dodecylbenzenesulfonate, dissolve it in 30g of deionized water, and add 45g of methyl methacrylate and 22g of butyl acrylate dropwise under stirring at a speed of 800rpm. Stir for 1 h after the addition to obtain a core layer pre-emulsion;

[0046] (2) Get 3g of sodium dodecylbenzenesulfonate, dissolve it in 30g of deionized water, and add dropwise 6g of methacrylic acid, 40g of hydroxyethyl methacrylate and 21g of butyl acrylate under stirring at 800rpm Esters, after 0.5h dropwise, stir for 1h after the dropwise addition, to obtain the shell layer pre-emulsion;

[0047] (3) Add 30g of deionized water and 0.3g of sodium dodecylbenzenesulfonate under nitrogen protection into a four-necked flask equipped with an agitator, condenser, and two-port connecting pipe, stir well, and place in a constant temperature water bath Heating to 85° C., adding dropwise 65 g of the core ...

Embodiment 3

[0050] Embodiment 3 Preparation of self-thickening acrylic acid emulsion

[0051] (1) Take 5g of sodium dodecylbenzene sulfonate, dissolve it in 25g of deionized water, and add 55g of methyl methacrylate and 15g of butyl acrylate dropwise under stirring at a speed of 1500rpm. Stir for 1 h after the addition to obtain a core layer pre-emulsion;

[0052] (2) Get 5g of sodium dodecylbenzene sulfonate, dissolve it in 25g of deionized water, stir with 1500rpm rotating speed, add dropwise the methacrylic acid of 8g, the hydroxyethyl methacrylate of 32g and the butyl acrylate of 30g Esters, after 0.5h dropwise, stir for 1h after the dropwise addition, to obtain the shell layer pre-emulsion;

[0053] (3) Add 55g deionized water and 0.4g sodium dodecylbenzenesulfonate under the protection of nitrogen in a four-necked flask equipped with a stirrer, a condenser tube, and a two-port connecting pipe, stir well, and place in a constant temperature water bath Heating to 80° C., dropwise ad...

PUM

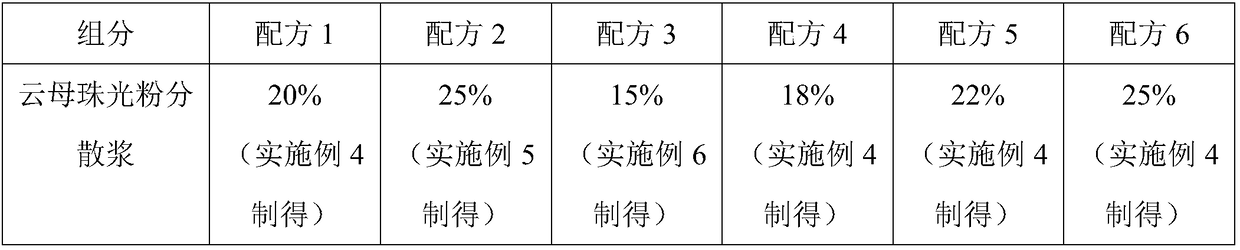

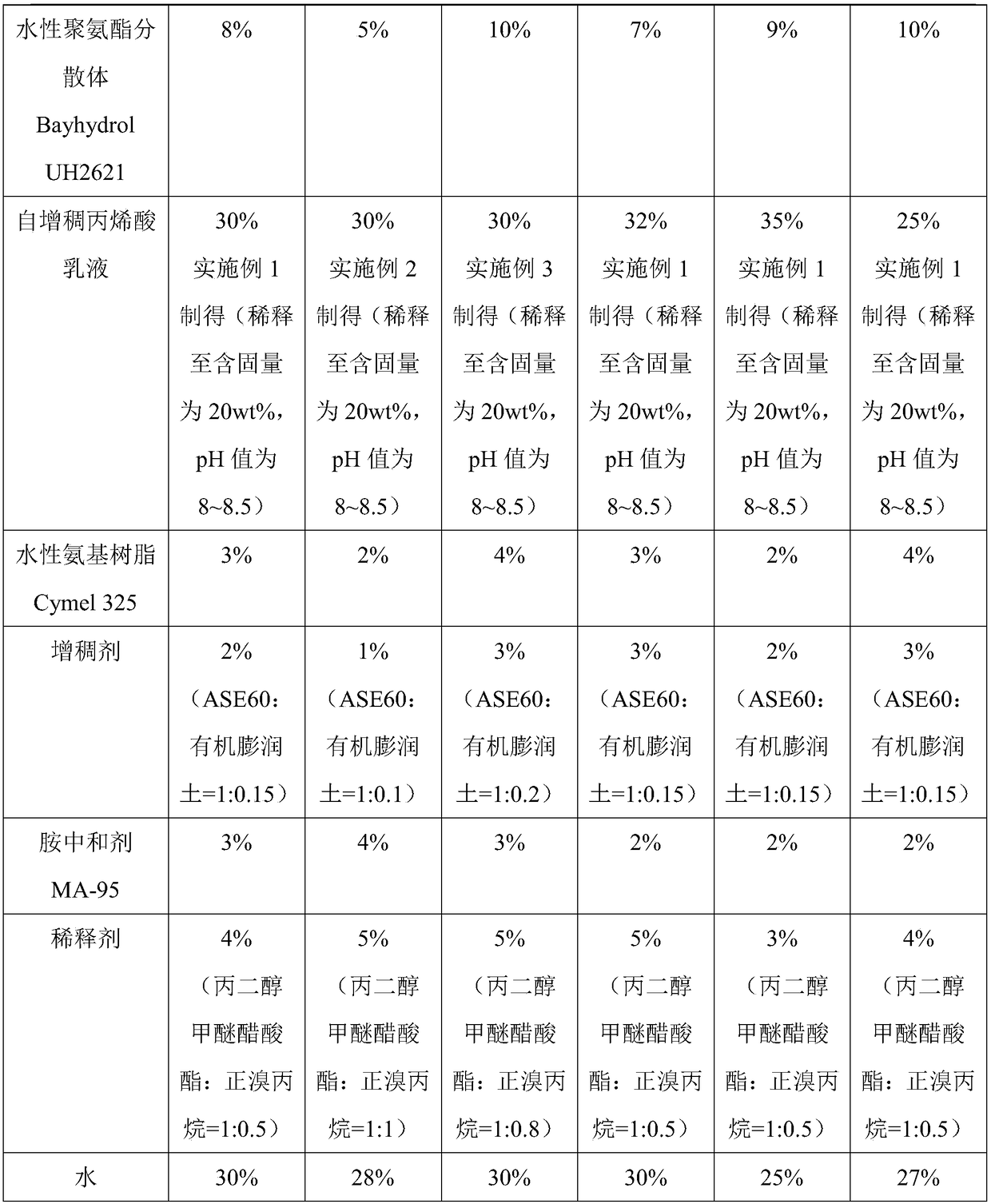

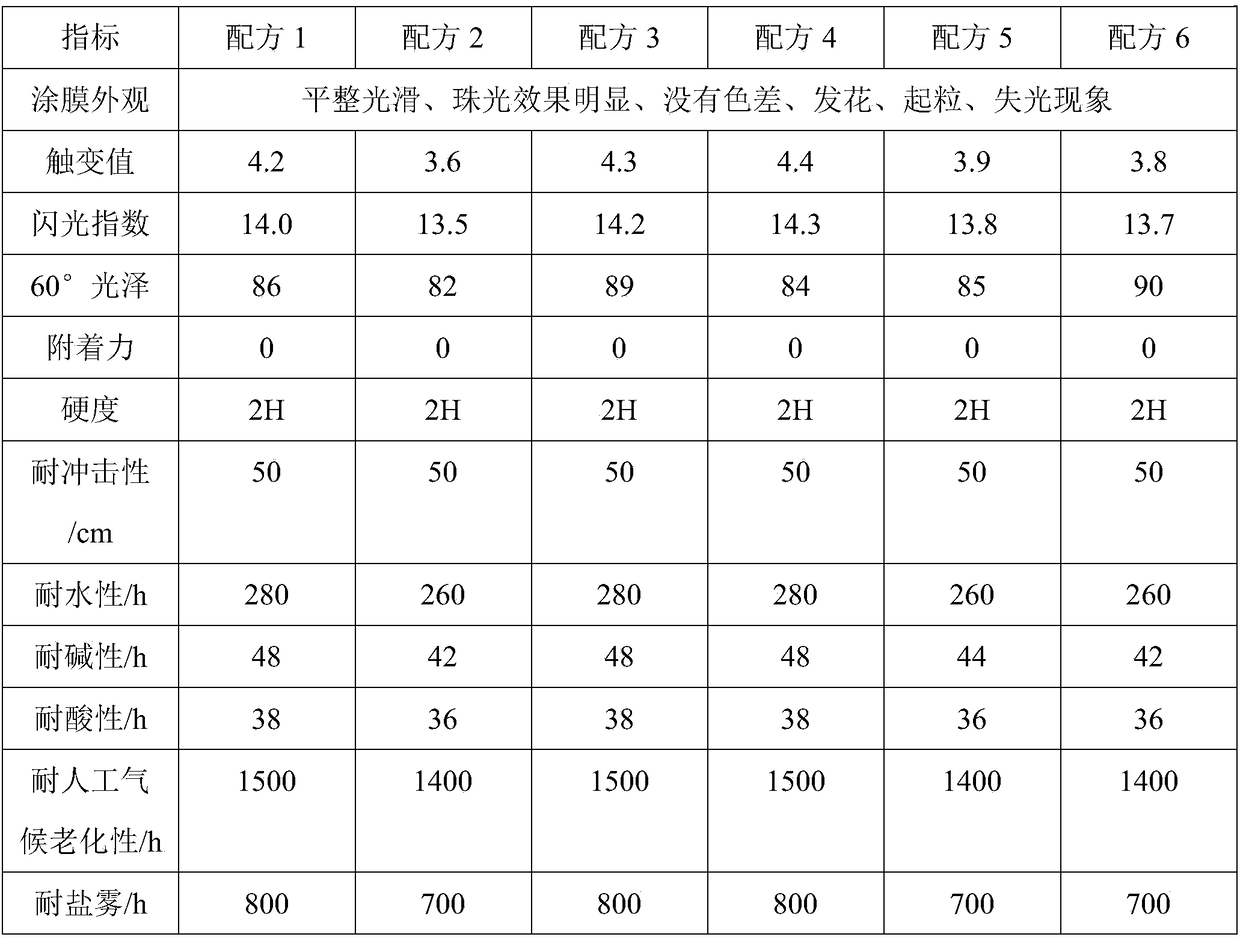

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com