Weather-resistant fluorocarbon powdery coating, and preparation method and application thereof

A powder coating and weather resistance technology, applied in powder coatings, polyester coatings, coatings, etc., can solve the problem that the weather resistance of the coating surface such as acid resistance, alkali resistance and aging resistance cannot be improved, and the adhesion of powder coatings , poor impact resistance, reduced weather resistance of the coating film, etc., to achieve the effect of saving manpower and material resources, beautiful touch, and soft appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The present invention provides a kind of weather-resistant fluorocarbon powder coating, comprising A component and B component compounded by weight ratio 1:3-3:1, wherein,

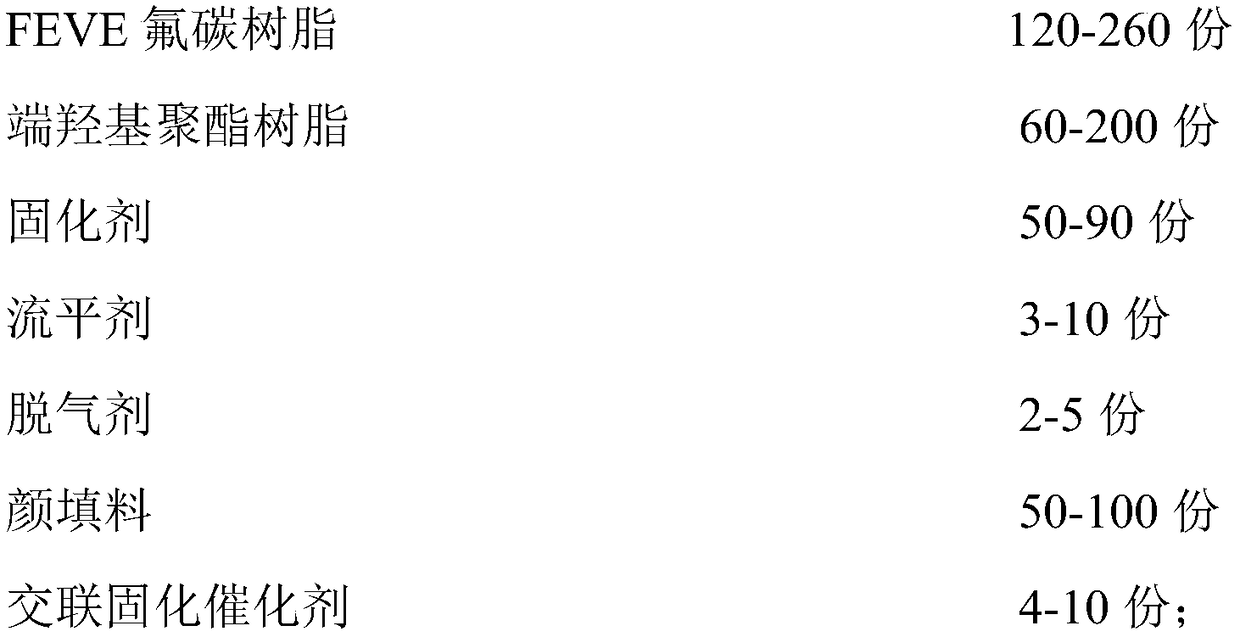

[0029] The A component includes the following raw materials in parts by weight:

[0030]

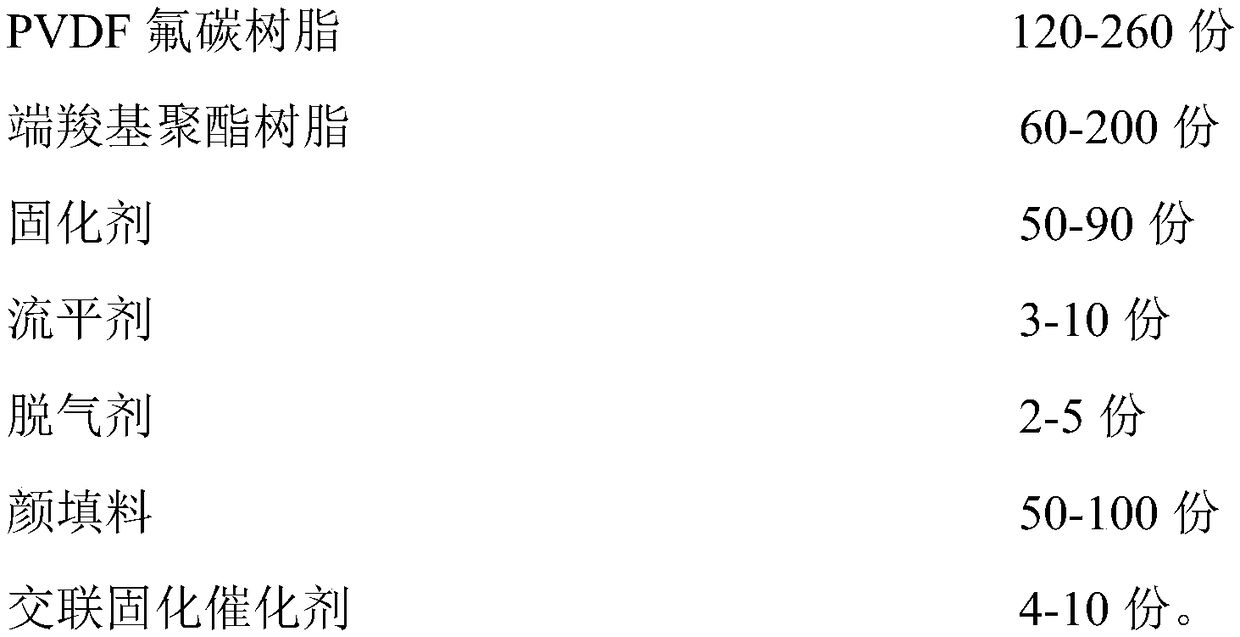

[0031] The B component includes the following raw materials in parts by weight:

[0032]

[0033]

[0034] The hydroxyl value of the hydroxyl-terminated polyester resin is 30-40 mgKOH / g, the melt rotation viscosity is 4000-8000 mPa·s / 200°C, and the glass transition temperature is 62-68°C.

[0035] The acid value of the carboxyl-terminated polyester resin is 30-55 mgKOH / g, the melt rotation viscosity is 3500-9000 mPa·s / 200°C, and the glass transition temperature is 50-60°C.

[0036] The curing agent is isophorone diisocyanate polymer blocked by caprolactam.

[0037] The leveling agent is polysiloxane or polyester modified polyether.

[0038] The degassing agent is benzoin.

[0039] The crosslinking...

Embodiment 2

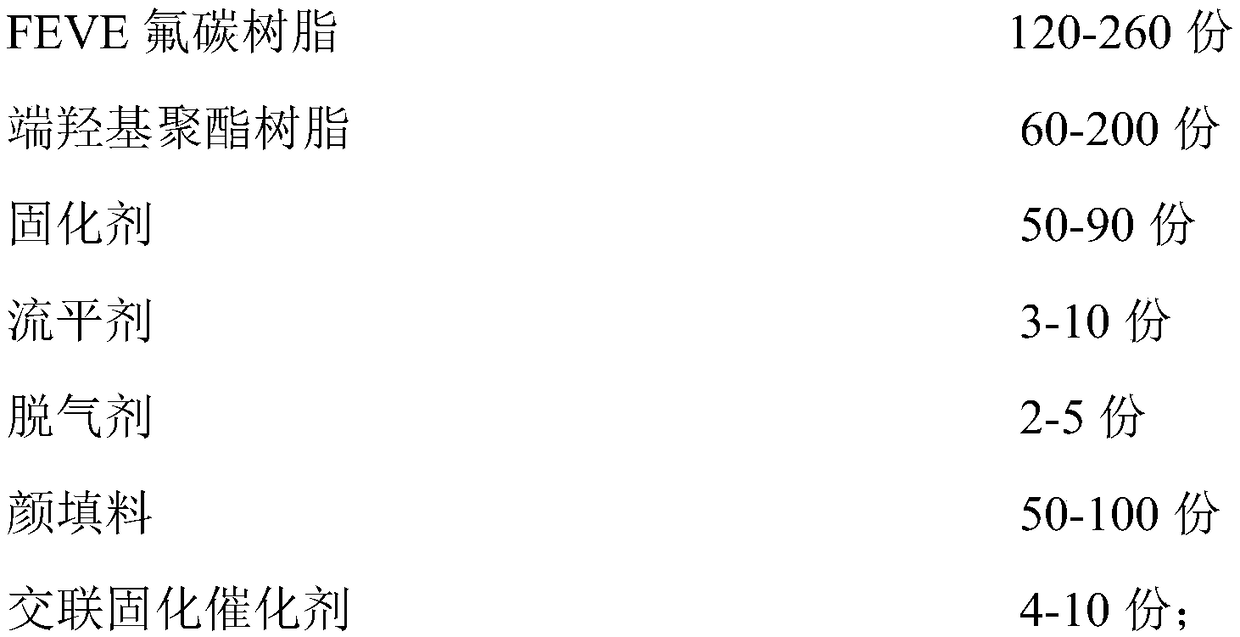

[0049] On the basis of Example 1, this Example 2 is a preferred example of weather-resistant fluorocarbon powder coatings, including A component and B component, and the A component includes the following raw materials in proportions by weight:

[0050]

[0051] The B component includes the following raw materials in parts by weight:

[0052]

[0053]

[0054] Wherein, the pigment and filler are a mixture of carbon black and titanium dioxide in a weight ratio of 1:1.

[0055] The preparation method of described weather resistance fluorocarbon powder coating, comprises the following steps:

[0056] (1) Preparation of component A: Put the FEVE fluorocarbon resin, hydroxyl-terminated polyester resin, curing agent, leveling agent, degassing agent, pigments and fillers and cross-linking curing agent into the mixing tank according to the corresponding proportion , after stirring and mixing at a speed of 130r / min for 6 minutes, set aside;

[0057] (2) Preparation of componen...

Embodiment 3

[0061] On the basis of Example 2, this Example 2 is a preferred example of weather-resistant fluorocarbon powder coatings, including component A and component B compounded at a weight ratio of 1:3-3:1, wherein,

[0062] The A component includes the following raw materials in parts by weight:

[0063]

[0064]

[0065] The B component includes the following raw materials in parts by weight:

[0066]

[0067] Wherein, the pigment and filler is a mixture of titanium dioxide, iron red powder and iron blue in a weight ratio of 3:2:2.

[0068] The preparation method of the powder coating adopts the preparation method in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com