Water-based intumescent flame-retardant paint based on modified boron nitride and preparation method thereof

A technology of fire retardant coating and boron nitride, applied in the direction of fire retardant coating, coating, etc., can solve the problem that the performance of water-based intumescent fire retardant coating is not good enough, and achieve excellent antifouling performance, good compatibility, high efficiency fire resistance and flame retardant performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

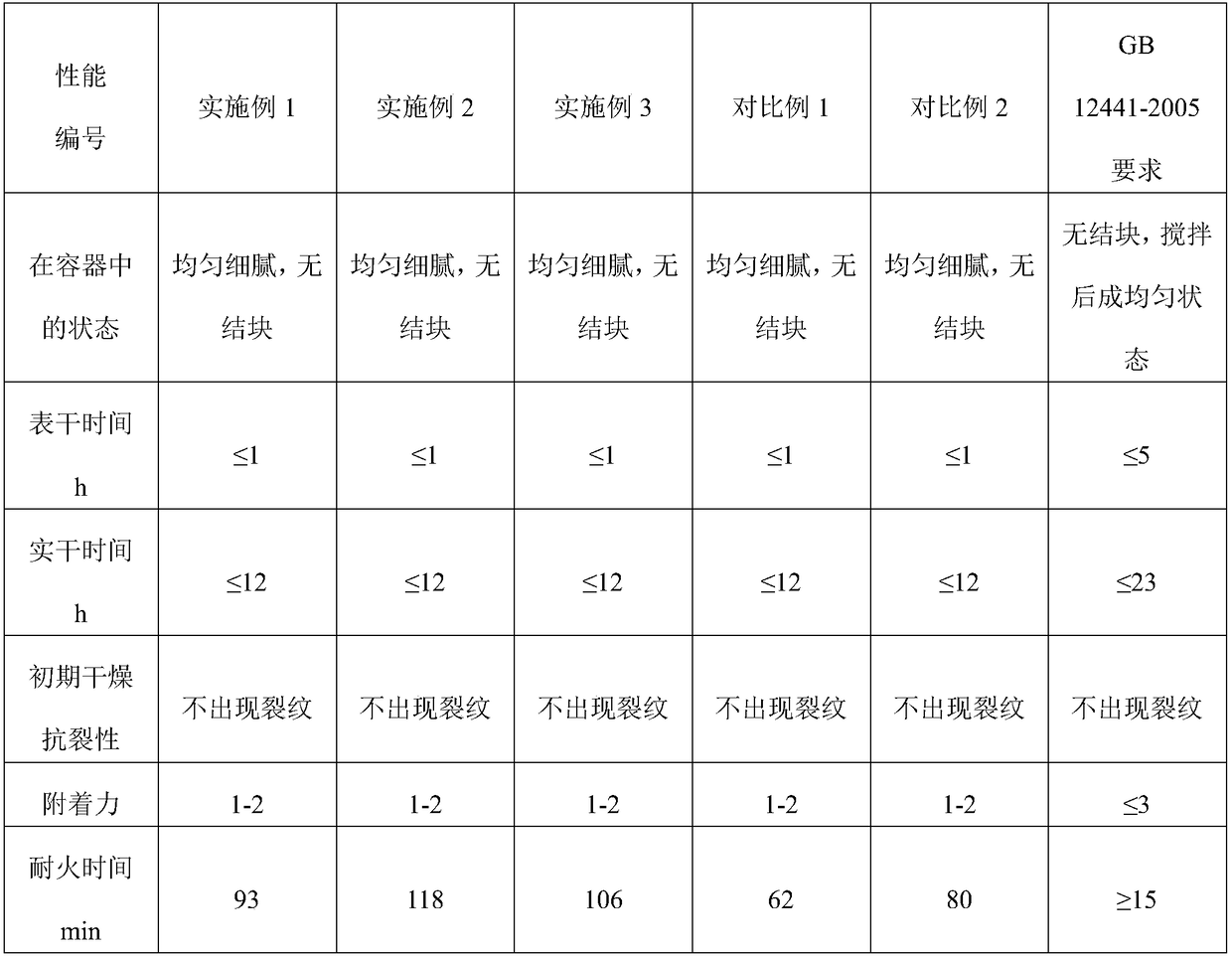

Embodiment 1

[0031] A water-based intumescent fireproof coating based on modified boron nitride, its composition is as follows (mass percentage): 2% of modified boron nitride, 36% of ammonium polyphosphate, 17% of pentaerythritol, 12% of melamine, water-based styrene-acrylic core-shell Emulsion 20%, hydroxyethyl cellulose 0.5%, dispersant 0.5%, defoamer 0.5%, n-octanol 0.5%, water 11%.

[0032] The preparation method of the water-based intumescent fireproof coating is as follows: prepare materials according to the above-mentioned ratio; mix and grind the weighed ammonium polyphosphate, pentaerythritol, melamine, and modified boron nitride into powder, then add water and continue to grind to make it evenly mixed , then add hydroxyethyl cellulose, defoamer and dispersant to continue grinding, and finally add water-based styrene-acrylic core-shell emulsion and n-octanol, grind thoroughly for the third time and mix well.

Embodiment 2

[0034] A water-based intumescent fireproof coating based on modified boron nitride, its composition is as follows (mass percentage): 6% of modified boron nitride, 34% of ammonium polyphosphate, 13% of pentaerythritol, 12% of melamine, water-based styrene-acrylic core-shell Emulsion 20%, hydroxyethyl cellulose 0.5%, dispersant 0.5%, defoamer 0.5%, n-octanol 0.5%, water 13%. The preparation method of the water-based intumescent fireproof coating is the same as that of Example 1.

Embodiment 3

[0036] A water-based intumescent fireproof coating based on modified boron nitride, its composition is as follows (mass percentage): 10% of modified boron nitride, 30% of ammonium polyphosphate, 12% of pentaerythritol, 11% of melamine, water-based styrene-acrylic core-shell Emulsion 20%, hydroxyethyl cellulose 0.5%, dispersant 0.5%, defoamer 0.5%, n-octanol 0.5%, water 15%. The preparation method of the water-based intumescent fireproof coating is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com