Polyimide film and preparation method thereof

A polyimide film and polyamic acid technology, which is applied in the field of polyimide film and its preparation, can solve the problems of easy brittle cracking of polyimide film formation, decrease in mechanical properties such as toughness, decrease in toughness of a substrate, and the like. Achieve the effect of promoting thermal conductivity improvement, reducing the number of microcracks, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A kind of polyimide film of the present invention, this polyimide film is made after casting, imidization stretching by polyamic acid solution composition, and polyamic acid solution composition mainly consists of the following components by weight Mix it up:

[0056] Polyamic acid resin 178.76g,

[0057] Dimethyl phthalate 10g,

[0058] Erucamide 10g,

[0059] Thermally conductive paste 124.77g.

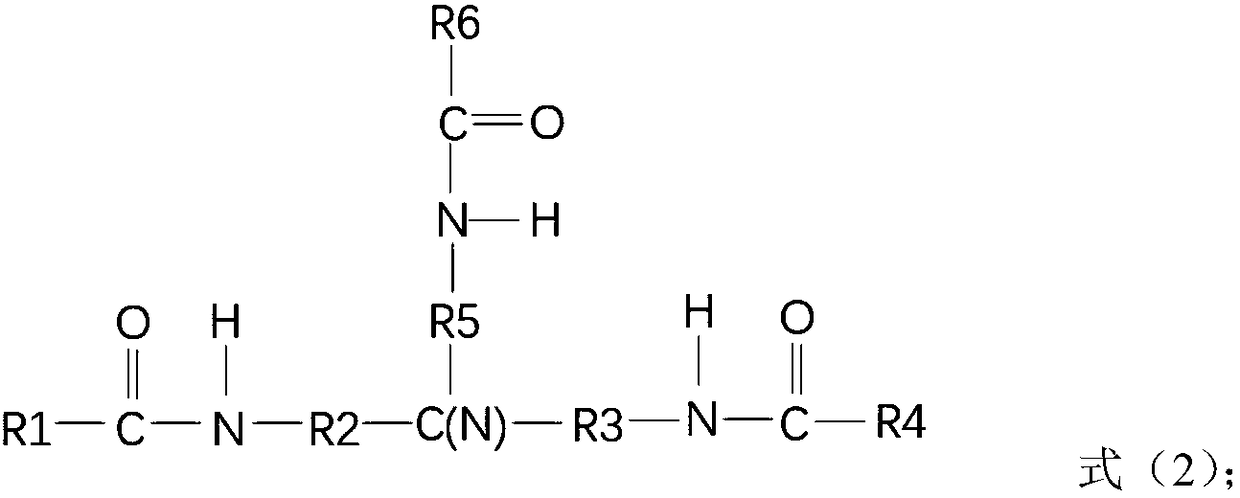

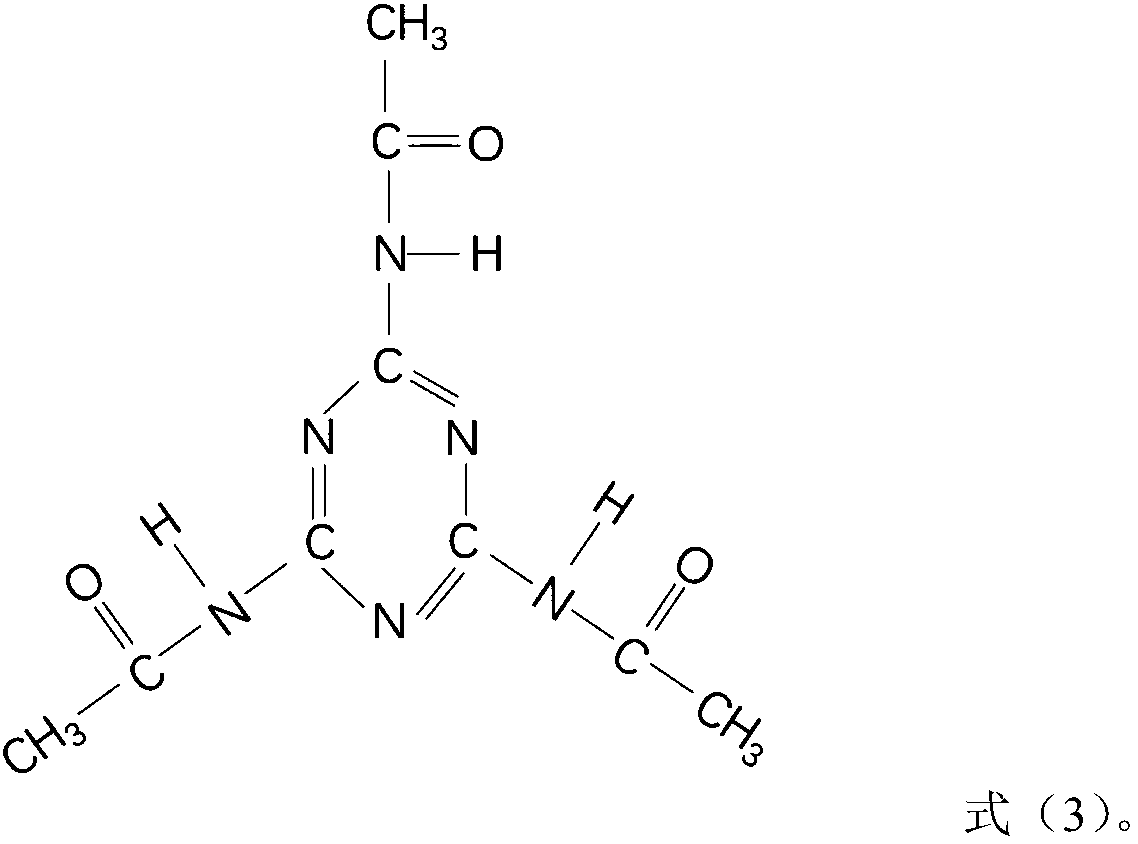

[0060] Among them, 20.02g (0.10mol) of polyamic acid 4,4'-diaminodiphenyl ether and 21.81g (0.10mol) of pyromellitic dianhydride were successively added to 136.93g of N,N-dimethylformamide for polymerization Formed; the thermally conductive paste is composed of 22.51g of alumina with a particle size of 1 μm, 1.13g of 4-aminopropylmethyldimethoxysilane, 1.13g of N-methylpyrrolidone solution of modified urea and 100g of N,N- Dimethylformamide mixed.

[0061] A kind of preparation method of polyimide film of the present invention, comprises the following steps:

[0062] (1...

Embodiment 2

[0066] A kind of polyimide film of the present invention, this polyimide film is made after casting, imidization stretching by polyamic acid solution composition, and polyamic acid solution composition mainly consists of the following components by weight Mix it up:

[0067] Polyamic acid resin 240.15g,

[0068] Dimethyl phthalate 10g,

[0069] Erucamide 10g,

[0070] Thermally conductive paste 130.20g.

[0071] Among them, polyamic acid is successively added to 189.11 by 20.02g (0.10mol) 4,4'-diaminodiphenyl ether and 31.02g (0.10mol) 2,3',3,4'-diphenyl ether tetracarboxylic dianhydride It is polymerized in gN,N-dimethylformamide; the thermally conductive paste is composed of 27.46g of alumina with a particle size of 1μm, 1.37g of 4-aminopropylmethyldimethoxysilane, and 1.37g of modified urea N -Methylpyrrolidone solution mixed with 100g N,N-dimethylformamide.

[0072] Example 2 Compared with Example 1, only the type of dianhydride was changed, and the same method as Exa...

Embodiment 3

[0078] A kind of polyimide film of the present invention, this polyimide film is made after casting, imidization stretching by polyamic acid solution composition, and polyamic acid solution composition mainly consists of the following components by weight Mix it up:

[0079] Polyamic acid resin 178.76g,

[0080] Dimethyl phthalate 15g,

[0081] Erucamide 15g,

[0082] Thermally conductive paste 124.77g.

[0083] Among them, polyamic acid is successively added to 136.93g N,N-dimethylformamide from 20.02g (0.10mol) 4,4'-diaminodiphenyl ether and 21.81g (0.10mol) pyromellitic dianhydride It is polymerized; the thermal conductive paste is composed of 22.51g of alumina with a particle size of 1μm, 1.13g of 4-aminopropylmethyldimethoxysilane, 1.13g of N-methylpyrrolidone solution of modified urea and 100g of N,N - Mixed with dimethylformamide.

[0084] Compared with Example 1, Example 3 only changed the amount of plasticizer and slip agent, and adopted the same method as Exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com