Preparation method of vinyl acetate sand fixing emulsion with damping capacity

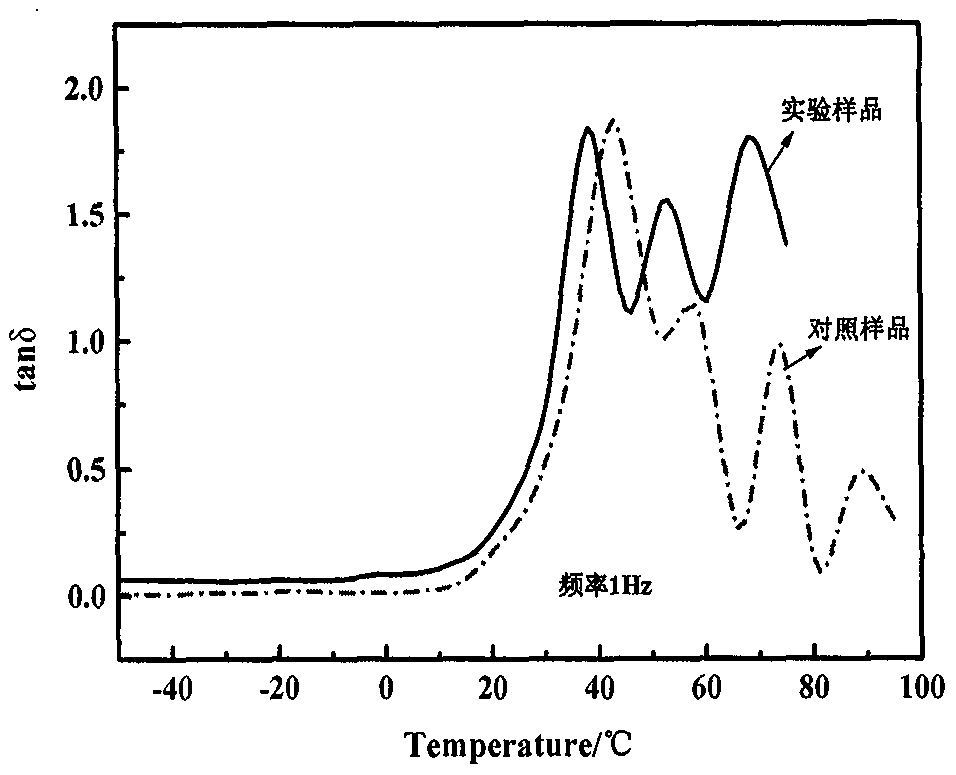

A vinyl acetate, sand-fixing emulsion technology, applied in chemical instruments and methods, organic fertilizers, applications, etc., can solve the problems of poor wind erosion resistance, short service period, long wind period, etc., achieve excellent damping performance, and enhance water retention. , the effect of speeding up the wind

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]Mix and disperse 0.3 parts of ammonium lauryl ether sulfate, 0.3 parts of polyethylene glycol 400 monolaurate, 0.3 parts of Span 85 and 40 parts of deionized water, then add 30 parts of vinyl acetate and 5 parts of methacrylic acid Methyl ester and 5 parts of lauryl methacrylate monomer were ultrasonically dispersed for 3 minutes to obtain a pre-emulsion. Dissolve 0.15 parts of potassium persulfate in 14 parts of deionized water and set aside. Add 16 parts of deionized water, 0.1 part of ammonium lauryl ether sulfate, 0.1 part of polyethylene glycol 400 monolaurate, and 0.1 part of Span 85 into the reaction kettle, heat and stir to raise the temperature to 80°C, and react for 15 minutes. Add 1 / 5 (mass fraction of the total weight of potassium persulfate) potassium persulfate solution, keep warm for 10 min, then slowly add 3 / 5 (mass fraction of the total weight of potassium persulfate) dropwise with a constant pressure dropping funnel Initiator and ultrasonic pre-emulsio...

Embodiment 2

[0044] Mix and disperse 0.4 parts of ammonium lauryl ether sulfate, 0.4 parts of polyethylene glycol 400 monolaurate, 0.4 parts of Span 85 and 40 parts of deionized water, then add 24 parts of vinyl acetate and 3 parts of methacrylic acid Methyl ester and 5 parts of lauryl methacrylate monomer were ultrasonically dispersed for 3 minutes to obtain a pre-emulsion. Dissolve 0.2 parts of potassium persulfate in 14 parts of deionized water and set aside. Add 16 parts of deionized water, 0.1 part of ammonium lauryl ether sulfate, 0.1 part of polyethylene glycol 400 monolaurate, and 0.1 part of Span 85 into the reaction kettle, heat and stir to raise the temperature to 80°C, and react for 15 minutes. Add 1 / 5 (mass fraction of the total weight of potassium persulfate) potassium persulfate solution, keep warm for 10 min, then slowly add 3 / 5 (mass fraction of the total weight of potassium persulfate) dropwise with a constant pressure dropping funnel Initiator and ultrasonic pre-emulsio...

Embodiment 3

[0046] Mix and disperse 0.2 parts of ammonium lauryl ether sulfate, 0.4 parts of polyethylene glycol 400 monolaurate, 0.3 parts of Span 85 and 40 parts of deionized water, then add 30 parts of vinyl acetate and 3 parts of methacrylic acid Methyl ester and 7 parts of lauryl methacrylate monomer were ultrasonically dispersed for 5 minutes to obtain a pre-emulsion. Dissolve 0.2 parts of potassium persulfate in 14 parts of deionized water and set aside. Add 16 parts of deionized water, 0.1 part of ammonium lauryl ether sulfate, 0.1 part of polyethylene glycol 400 monolaurate, and 0.1 part of Span 85 into the reaction kettle, heat and stir to raise the temperature to 80°C, and react for 15 minutes. Add 1 / 5 (mass fraction of the total weight of potassium persulfate) potassium persulfate solution, keep warm for 10 min, then slowly add 3 / 5 (mass fraction of the total weight of potassium persulfate) dropwise with a constant pressure dropping funnel Initiator and supersonic pre-emulsio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com